[Shenzhen, China2025] — Jade Mago, a B2B manufacturer specializing in semi-precious stone processing, presented its newest scalable product line—the Crystal Mask—at China (Shenzhen) International Gifts and Home Products Fair, welcoming product teams, buyers, and brand owners to review a real-world “prototype-to-production” workflow. The showcase focused on what matters most after a show: whether a product can be sampled predictably, produced consistently, and delivered with controlled variance when natural materials are involved.

At the booth, visitors were able to evaluate the Crystal Mask across key procurement checkpoints: material selection, assembly stability, finishing consistency, and packaging readiness. Rather than positioning the product as a one-off display piece, Jade Mago introduced it as a repeatable SKU framework—with defined dimensions, verified assembly logic, and manufacturing controls designed for scale.

Table of Contents

Event Snapshot: What Buyers Came to Validate

Jade Mago’s presence at China (Shenzhen) International Gifts and Home Products Fair was designed around a simple question buyers ask after every meeting: “Can this go from a good sample to reliable production?” Across cross-border brands and studio buyers alike, the conversations were less about trend narratives and more about feasibility, lead time ranges, and how quality decisions are documented across batches.

The booth team included both sales and production-side support so visitors could speak about design feasibility in practical terms. Discussions covered target dimensions, edge finishing, comfort contact areas, stone variability, and how to structure sampling so that approval criteria remains stable when production volume increases.

What’s New This Year: The Crystal Mask Built for Stable Mass Production

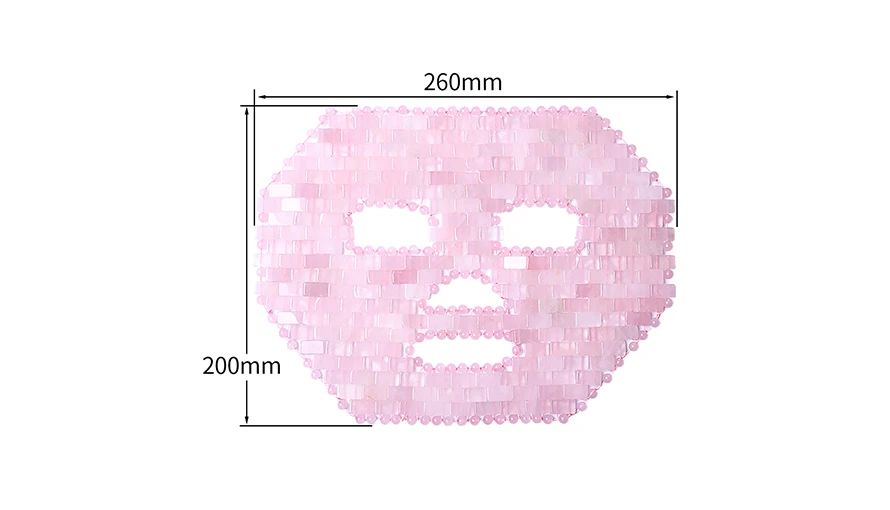

The Crystal Mask is a wearable cold-compress-style accessory designed for a cooling feel and comfort-fit coverage. It is built from multiple stone segments assembled into a flexible structure, supporting controlled drape over facial contours. This makes the product both visually premium and manufacturing-sensitive, because consistent comfort depends on consistent segment geometry and assembly spacing.

Jade Mago developed this product line with mass production in mind. That means the engineering focus is not only “how it looks on day one,” but also how the design performs across repeated cutting cycles, finishing, inspection, and packaging in day-to-day factory conditions.

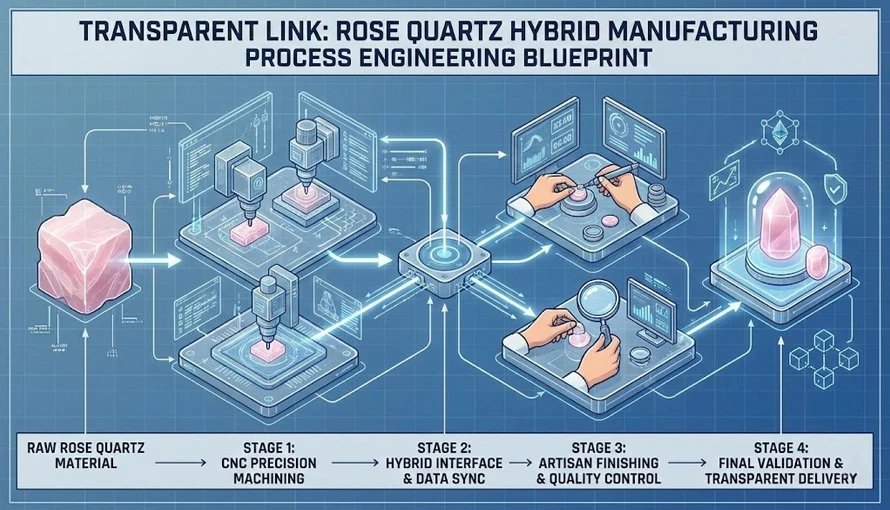

CNC Precision Cutting for Repeatable Segment Geometry

For scalable stone products, consistent geometry is a foundational requirement. Jade Mago’s approach begins with CNC-driven precision cutting for the repeating units used across the Crystal Mask structure. When segment geometry is stable, assembly becomes more predictable, and comfort-related features—such as smooth edges and consistent spacing—are easier to manage.

That said, natural stone is not a uniform industrial substrate. Even when geometry is consistent, final yield and surface behavior can vary based on internal structure, micro-fractures, or inclusions. For this reason, Jade Mago uses CNC as a repeatability tool and pairs it with inspection logic designed for natural material realities.

Hybrid Workflow: CNC + Finishing Controls for Wearable Comfort

Wearable stone products require more than dimensional accuracy. Edges, corner radii, and skin-contact surfaces must be managed carefully to achieve a comfortable feel and reduce sharpness risk. Jade Mago’s production plan for the Crystal Mask follows a hybrid workflow: CNC creates stable base geometry, and finishing controls refine contact surfaces and visual consistency.

This hybrid method also creates clear handoff checkpoints. Each checkpoint is a risk-control point where surface condition and edge integrity can be evaluated before additional labor or polishing steps are applied. For buyers, this translates into clearer acceptance criteria and fewer surprises during scale-up.

Prototype-to-Production Support: Turning a Concept into a Scalable SKU

Many show visitors come with a moodboard rather than a complete technical package. Jade Mago supports scale-up through a structured feasibility process that turns early designs into production-ready specifications. For the Crystal Mask, that includes mapping the design into standardized segment formats, defining assembly logic, and documenting inspection criteria that can be used consistently by QC teams.

For brands and procurement teams, this feasibility support reduces the common failure mode of “a beautiful sample that can’t be repeated.” It also enables clearer quotation logic, because material choices, finishing expectations, and inspection intensity are defined before mass production begins.

Product Highlights: Crystal Mask as a Commercial-Ready Line, Not a One-Off

The Crystal Mask was introduced as a product line with a scalable manufacturing base. The core design is compatible with multiple stone options and finish directions, enabling private-label buyers to position the product within different price tiers and branding narratives. This is especially relevant for wellness and beauty accessory categories where brands often require both signature colorways and repeatable replenishment.

Below are the key attributes discussed most often at the booth, framed in buyer language rather than consumer hype.

Cooling Use Case: Designed for Cold-Compress Scenarios

The Crystal Mask supports cold-compress use by allowing the stones to be cooled (for example, via refrigeration) and then applied for a cooling sensation. Many visitors asked about “de-puffing” positioning. Jade Mago’s guidance is to keep language compliant and practical—describe the product as a cooling accessory and avoid medical claims or guaranteed outcomes.

For B2B buyers, the more important point is that the Crystal Mask structure is designed to maintain its assembly integrity and surface finish across repeated handling. A product that chips easily or varies heavily in fit becomes a returns risk, regardless of marketing claims.

Comfort-Fit Geometry: Where Wearable Stone Needs Extra QC

Unlike decorative carvings, wearable stone must be managed for contact comfort and fit perception. The Crystal Mask design uses a multi-segment structure that aims to drape rather than rigidly press. This reduces the feeling of “hard edges,” but it also increases the importance of consistent segment thickness and edge finishing.

Jade Mago highlighted comfort-related QC controls at the show, including edge smoothness checks, surface micro-chipping inspection, and assembly spacing verification. These are the types of controls that protect buyer brands at scale because comfort is difficult to “fix later” once the product is packaged and shipped.

A Stable Base for Customization: Color, Stone Type, and Branding

The product line can be developed in multiple stone options, such as rose quartz and other semi-precious stones depending on sourcing and design requirements. The brand can choose a consistent visual direction (soft, translucent, or higher-contrast looks) and pair it with packaging and messaging aligned to their market.

For OEM/ODM buyers, the key is not only the stone name but also the disclosure clarity and repeatability controls. Jade Mago recommends confirming stone type definitions, material disclosure expectations, and batch acceptance ranges early in development so that marketing language stays aligned with product reality.

Materials & Manufacturing Reality: Why “Same Design” Can Produce Different Outcomes

Natural stone introduces variability that must be managed rather than denied. Even within the same stone category, variations in translucency, internal structure, and inclusions can influence finishing response and yield. This is why mass production success depends on setting acceptance criteria and communicating variance expectations in measurable terms.

At the booth, Jade Mago aligned with buyers on a practical approach: define what must be consistent (dimension ranges, edge finish, assembly stability) and what can be allowed to vary (minor internal patterning, natural color movement within an approved window). This approach helps procurement teams protect their brands without overpaying for unrealistic constraints.

Rose Quartz and Visual Consistency Planning

Rose quartz is often selected for its soft color and gentle aesthetic. Buyers typically want consistency in tone and clarity, but in natural materials, “perfectly identical” is an unrealistic standard. Jade Mago recommends building a visual standard set: approved reference samples that represent the acceptable range for color and translucency.

This allows production to be controlled with an operational standard rather than a subjective one. It also helps brands create honest product listings and reduces disputes caused by mismatched expectations between marketing images and real shipped goods.

Yield, Chipping Risk, and Edge Controls

Wearable, thin-segment stone products can be sensitive to micro-chipping if edges are not managed properly. The Crystal Mask production plan therefore emphasizes edge control as a first-class requirement, not an afterthought. The goal is to reduce sharpness risk, reduce visible chipping rates, and keep the product visually premium at typical viewing distance.

Jade Mago discussed with visitors how inspection checkpoints and finishing choices impact yield. More aggressive polishing may improve feel but can expose weak points in certain stone pieces, while overly light finishing can leave edges that feel less refined. A balanced process tuned to the chosen material is part of making the product scalable.

Transparency & Disclosure: Protecting Buyer Brands in Cross-Border Markets

In international trade, compliance and disclosure are not optional. Buyers increasingly request clear material descriptions, consistent labeling language, and a practical approach to documentation. Jade Mago positioned transparency as a core part of the Crystal Mask’s scale-up strategy, because returns, listing disputes, and platform policy issues can cost more than the product margin.

This section became particularly relevant for brand buyers selling into markets with strict consumer protection rules. Rather than using blanket claims, Jade Mago recommends documentation and language that match the buyer’s market needs and the material realities of the specific batch.

Treatment Disclosure Without Over-Claiming

In the gemstone and stone accessories sector, confusion often arises between “natural origin,” “treated,” and “synthetic.” A product can be natural in origin and still have undergone treatments. The commercial risk is rarely the treatment itself—it is the lack of disclosure, inconsistent labeling, or overconfident claims that cannot be supported across batches.

Jade Mago’s approach is to align on buyer requirements early. If a buyer needs specific documentation or third-party testing for certain markets or retail channels, this should be planned during sampling, not after production has started.

Testing Strategy as a Buyer Option

Some buyers asked about test reports or verification methods. Jade Mago can support a structured approach where testing is selected based on risk level, channel requirements, and the buyer’s compliance policy. The key is to avoid implying absolute guarantees when testing scope is limited, and to clearly state what was tested and what was not.

For B2B buyers, this approach is a practical middle ground. It supports responsible sourcing communication while avoiding language that could become a liability later.

Booth Conversations: What Product Teams and Procurement Asked Most

Across discussions at China (Shenzhen) International Gifts and Home Products Fair, recurring questions followed a consistent pattern. Buyers were not only excited by the product concept, but also focused on risk points that can break a launch when scaling. Jade Mago used these questions to explain the Crystal Mask as a controllable manufacturing project rather than a decorative novelty.

Top Questions from Product Managers and Designers

Product teams asked how the mask could be adapted for different brand identities without destabilizing production. The most common customization requests included stone type changes, segment format adjustments, and packaging updates. Jade Mago’s answer was to keep structural geometry stable and shift brand identity through material selection, finish direction, and packaging language.

Designers also asked about comfort perception and how to avoid a “rigid” feel. The multi-segment assembly is designed to drape, but comfort depends on finishing and assembly quality. Jade Mago recommended building comfort checkpoints into the sampling plan so that fit feedback is captured before mass production.

Top Questions from Procurement and Sourcing Teams

Procurement teams asked about lead time ranges, sampling structure, and how to avoid batch inconsistency. Jade Mago’s guidance was to treat sampling as a process, not a single event: prototype confirms the concept, pilot confirms repeatability, and production confirms operational stability.

Buyers also asked what information is required for accurate quotations. Jade Mago recommended sending target dimensions, desired finish level, target order volume, preferred stone options, and market destination requirements. This allows the factory to propose a process plan with clear inspection checkpoints and realistic variance language.

Why This Launch Matters: A “Mass-Producible Wellness Accessory” Approach

The market is full of products that photograph well but fail during replenishment. Jade Mago’s Crystal Mask launch is positioned around the opposite promise: not “perfect in theory,” but “repeatable in practice.” By building manufacturing controls into the product line, the company aims to support brands that need consistent restocks rather than limited runs.

For cross-border brands, stable production is a competitive advantage. When a SKU can be replenished reliably, brands can invest more confidently in marketing, distribution, and customer support. When a SKU cannot be replenished, growth slows and buyer trust declines.

This is why Jade Mago focused on practical scale-up discussions at the show—tolerances as ranges, comfort as measurable criteria, and transparency as a risk control. The result is a product line designed to match the operational demands of B2B buyers.

Next Steps: How to Start a Crystal Mask OEM/ODM Project with Jade Mago

Jade Mago welcomes qualified buyers who want to develop or private-label the Crystal Mask line. To reduce back-and-forth and speed up evaluation, the team recommends preparing a short project brief that includes the information below. This makes it easier to provide a clear feasibility response and a realistic sampling plan.

For Product Teams & Designers: What to Send

Send a simple package containing target dimensions, reference images, desired finish direction, and any comfort-related priorities. If you already have a CAD file, include it, but it is not required for initial evaluation. A clear description of the intended market positioning helps the factory recommend the right material options and finishing level.

If your brand wants to differentiate through geometry changes, discuss those changes early. Some modifications can be made without destabilizing production, while others may require new tooling logic or introduce yield risk. Early feasibility review saves time and cost.

For Procurement: What We Align on First

Procurement teams typically want to confirm MOQs, lead time ranges, quality acceptance language, and packaging readiness. Jade Mago can propose a sampling path that matches your channel requirements and compliance expectations. If you sell in regulated markets or strict platforms, share those requirements during sampling so documentation can be aligned from the start.

Jade Mago also recommends defining a “reference sample set” once the pilot is approved. This set becomes the shared quality language between your team and the production line, reducing disputes and improving consistency across replenishment orders.

Call to Action

If you met Jade Mago at China (Shenzhen) International Gifts and Home Products Fair, you can continue the discussion by requesting a feasibility review or a sample evaluation. If you did not attend the show, you can still contact the team to receive the Crystal Mask product brief and discuss customization paths.

CTA options to place on the page:

- Request Crystal Mask sample set

- Submit your target specs for feasibility review

- Book a technical call (OEM/ODM evaluation)