Introduction

If you’re sourcing Chinese jade jewelry, you’ve probably heard two extreme claims: “CNC is the future—machines can do everything,” or “Only hand-carving is real quality.” In procurement reality, both statements are unhelpful. What matters is whether a supplier can deliver repeatable batches without letting natural stone risks blow up your lead time.

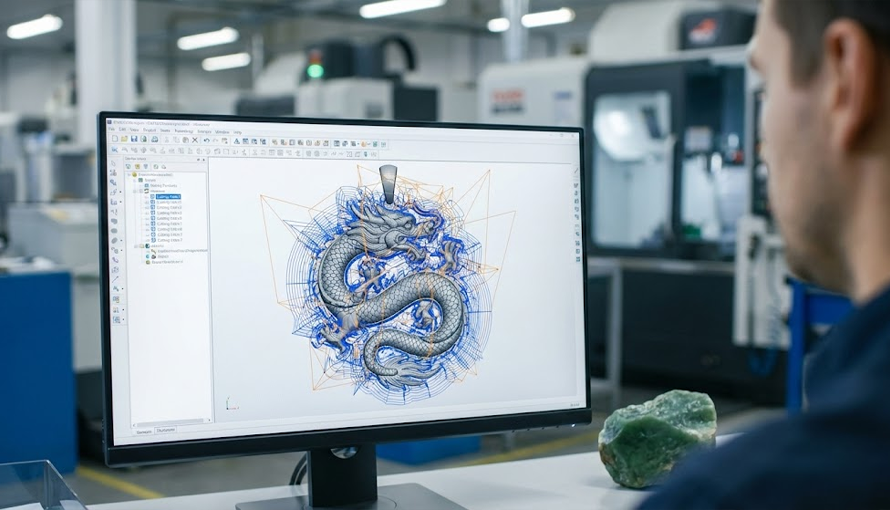

5-axis CNC is powerful for jade because it can control geometry, symmetry, and consistency—but it can’t “sense” what the stone is about to do. Jade may look stable on the surface and still contain internal stress lines or micro-cracks that only reveal themselves once cutting starts. That’s why experienced factories don’t treat CNC as an all-in-one solution. They treat it as one stage in a controlled workflow, and they define exactly where manual intervention is required to protect yield and finishing quality.

In this guide, we’ll map the real boundary: what 5-axis CNC can reliably achieve in complex Chinese motifs, where precision stops being the main problem, and which steps still need a master’s hand to keep production stable and auditable.

Table of Contents

The quick answer

CNC is Consistent, But Every Piece of Jade is a Wildcard

If you’re evaluating a supplier, the simplest truth is this: CNC repeats a toolpath, but natural jade doesn’t repeat its internal structure. CAD/CAM assumes homogeneous material; jade violates that assumption, so “same file, same result” is a myth in stone manufacturing.

That does not mean CNC is “bad.” It means CNC is excellent when your risk is mainly process variance, and less forgiving when your risk is material variance—especially hidden defects that only show up under stress.

The equilibrium you should look for in a factory audit

A professional factory doesn’t argue “machine-made vs handmade.” They run a hybrid workflow: CNC for roughing and controlled geometry, then manual refinement and finishing at defined handoff points, with inspection gates between stages.

In other words: automate what is predictable, and reserve judgment for what isn’t. That’s what stabilizes yield and delivery timelines for complex Chinese motifs (cloud patterns, openwork, deep relief, thin edges).

What “precision” means in Chinese jade jewelry (and what it doesn’t)

Dimensional precision vs artistic precision

In a procurement conversation, “precision” gets used as a single word, but you should split it into two ideas. Dimensional precision is about sizes, symmetry, hole positions, thickness targets, and repeatable geometry. Artistic precision is about how alive the relief feels, how the transitions behave under light, and how the surface finishing hides or reveals tool marks.

5-axis CNC is built for the first category. It can deliver strong repeatability because parameters and toolpaths are controlled digitally, and it scales well for standardized designs.

Why there is a real ceiling in jade

In jade, the ceiling is not only “machine resolution.” The real ceiling is that processing introduces stress (cutting forces, vibration, heat, stress redistribution), and that stress can reveal internal problems that had no surface expression before manufacturing started.

That’s why a piece can look visually clean at incoming inspection and still fail mid-process. From a physics perspective, the defect often existed already; processing simply triggered it, which is a material reality rather than proof of negligence by default.

Where 5-axis CNC is genuinely strong for complex Chinese motifs

Repeat geometry is CNC’s home turf

When your design has repeatable geometry—matching pairs, standardized silhouettes, repeated cloud patterns, consistent spacing, symmetric relief depth—CNC tends to outperform purely manual carving on consistency. It prioritizes dimensional accuracy and repeatability, which is exactly what procurement teams need when they’re responsible for batch delivery stability.

For audits, this is where you should ask for evidence. A capable supplier should show you how they control referencing, fixturing, and the way they preserve datum surfaces across stages. Even without sharing proprietary settings, they can show you how they keep parts consistent across batches.

Scalability and predictability (the real procurement KPI)

CNC’s efficiency advantage appears only when yield is predictable. When yield is stable, CNC becomes your best friend for lead time and repeat orders. When yield is unstable, CNC failures become expensive because they are often “binary” (pass/fail) rather than partially recoverable.

So in supplier evaluation, don’t ask, “Do you have 5-axis machines?” Ask, “On which material grades and design families is your yield stable enough that CNC is the right choice?” That question separates real factories from brochure factories.

The hard limits: where CNC stops being “the answer”

Hidden fractures don’t care about your toolpath

Hidden fractures are internal micro-cracks or stress planes that leave no surface trace. They can be structurally dormant until processing stress is applied, which is why pre-processing inspection often fails to detect them reliably with routine methods.

Once machining stress exceeds internal tolerance, dormant fractures open and crack propagation accelerates. To an untrained buyer, it looks like the stone “suddenly cracked,” but the origin and trigger are not the same thing.

From an audit perspective, the question is not “Can you prevent all cracks?” because routine manufacturing cannot. The question is “Do you have a workflow that limits loss probability and limits loss impact?” That’s what a professional supplier should be optimizing for.

CNC doesn’t adapt in real time the way a master does

CNC runs defined parameters and executes toolpaths without the tactile feedback a master uses. Hand carving adjusts depth, pressure, and path continuously as resistance changes; CNC follows the design regardless of material feedback.

This is why the same design can produce different outcomes across different processes. And it is why you should not accept “it’s 5-axis so it’s fine” as a qualification statement.

Toolpath strategy matters more than the machine brand

Two factories can own similar machines and still deliver different results because CNC outcome is often determined more by strategy than hardware. Toolpath direction influences stress accumulation and crack propagation, and aggressive parameters increase speed but amplify hidden defects.

For procurement screening, this is an important audit trick: ask the factory to explain, in simple terms, how they choose “conservative vs aggressive” strategies for new designs. If they can’t explain it, they likely can’t control it.

The “must-touch-by-hand” steps (mandatory human intervention points)

1) Material pre-evaluation and orientation decisions

Before cutting, a master-level decision is often required: how to orient the rough to reduce catastrophic risk while protecting the best visual zones. Orientation is not cosmetic; it is a structural trade-off, and it influences how stress travels through the stone during removal.

In hybrid workflows, material pre-evaluation and orientation are explicitly listed as the first step. If a supplier doesn’t treat this as a formal stage, they are likely relying on luck rather than process.

2) Conservative CNC roughing (and knowing when to stop)

A strong factory uses CNC for rough shaping or bulk material removal, but does it conservatively for new or high-risk rough. The point is not maximum speed; it’s stable yield and controlled stress exposure.

This is where procurement should look for discipline: do they have rules for step-down, entry/exit strategy, and avoiding sharp direction changes that concentrate stress? Toolpath geometry can drive stress behavior; stress follows toolpath geometry, not the visual design geometry.

3) Mid-process inspection for crack exposure (non-negotiable checkpoint)

Hybrid workflows treat the handoff points as risk checkpoints. One critical checkpoint is after roughing: inspect for new crack lines, edge breakout, or zones where the material “opened up” under stress.

This is where manual judgment beats automation. A master can decide whether to adjust the design slightly, change the finishing plan, or redirect a piece into a different product grade rather than forcing it through a rigid path.

4) Manual refinement and adaptive carving

Manual refinement is not a romantic flourish. It’s a practical response to the fact that natural stone does not behave like metal or plastic, and real-time adaptation is required when resistance and structure differ piece by piece.natural stone does not behave like metal or plastic, and real-time adaptation is required when r

In procurement language, manual refinement is the supplier’s method of variance absorption. It’s how they keep a batch within an acceptable range when the stone doesn’t cooperate.

5) Final polishing and surface finishing (the last 5% is where failures spike)

Final finishing is where thin features, undercuts, and surface transitions are most vulnerable. Even if CNC produced perfect geometry, finishing can still trigger fracture exposure because polishing introduces stress and heat, and because material equilibrium shifts as mass is removed.

A factory that treats finishing as “just polishing” is risky. A factory that treats it as an engineered stage with constraints and checkpoints is usually the one you can scale with.\

What a “good” factory looks like in an audit (practical checklist)

Ask for a process map, not just a machine list

A professional factory can show a process map that includes: pre-evaluation and orientation, CNC roughing, inspection, manual refinement, final finishing. They should frame the handoff points as checkpoints, because each handoff point is a risk checkpoint in hybrid manufacturing.

If the supplier says, “We do everything on CNC,” that might be true for low-risk designs and highly uniform material. But for complex Chinese motifs and natural jade variability, it often signals higher scrap volatility unless they have unusually strict material selection and screening discipline.

Look for the ability to talk about yield without over-promising

Professional factories manage ranges, not absolutes. Process consistency does not equal product consistency in natural stone, and irreducible randomness exists because internal micro-cracks, orientation, density, and stress distribution differ piece by piece.

So a mature supplier will never promise “zero defects,” “identical batches,” or absolute uniformity. They’ll use tolerance ranges, risk explanations, and manufacturing limitations instead of marketing guarantees.

Evaluate their “same file, same result” maturity level

If your procurement team hears “same file, same result,” treat it as a red flag. In natural stone, each piece becomes a new experiment because CAD/CAM assumptions don’t match material reality.

A credible supplier will explain why variance exists, how they shift probabilities through process design, and where they draw boundaries on what can be controlled versus only mitigated.

Verify that they can separate “origin” from “trigger” in failures

When cracks appear mid-process, weak suppliers blame the customer or the stone in an unstructured way. Strong suppliers explain the mechanics: many fractures exist below the visible surface; processing introduces stress; fracture exposure is a material reality by default, not automatically a process mistake.

That explanation is not an excuse. It’s the foundation for a risk-managed workflow that reduces loss rates without pretending that loss can be eliminated.

The hybrid workflow that tends to pass procurement audits

The baseline workflow (what “professional standard” looks like)

A typical hybrid process involves CNC roughing for bulk material removal, manual carving for detail/correction/finishing, and iterative inspection and adjustment between stages. The goal is to automate what is predictable and human-handle what is not.

A supplier that can show this workflow clearly—and show what they inspect at each gate—is usually the supplier that can deliver stable timelines on medium-to-large batches.

Why hybrid often beats pure CNC for complex motifs

CNC excels at volume removal, not anomaly response. Natural stone variability defeats rigid toolpaths, and manual correction prevents small defects from becoming failures.

From a procurement lens, this matters because hybrid workflows tend to reduce catastrophic breakage risk and improve average yield, which stabilizes delivery. The cost savings come from risk reduction rather than speed alone.

Cost and lead time

Price differences often reflect risk allocation, not margin

If two suppliers quote very different prices for “the same design,” one common reason is how they allocate risk. In stone manufacturing, price often reflects variance management rather than perfection, especially when tolerance expectations are narrow and rejection risk is high.

A supplier who prices low while promising high consistency may simply be underestimating risk. That can turn into delays, rework, or downstream disputes when the batch hits the failure range.

Why “just automate more” doesn’t guarantee lower cost

More automation does not always mean cheaper in stone processing. Hybrid systems often optimize cost by reducing failure probability and stabilizing delivery, while pure hand carving can reduce breakage risk but limits absolute precision and scalability.

So the best procurement outcome isn’t “maximum CNC.” It’s “right tool for the right stage, with checkpoints.”

A procurement-friendly “what to ask for” packet (no legal talk, just operational alignment)

What to request from the supplier

Ask for a simple packet that includes: a process map, sample photos across a batch, QC gate descriptions, and a short explanation of where they switch from CNC to hand work. This keeps your evaluation operational and comparable across vendors.

If the supplier starts using absolute language (“guaranteed,” “fully certified,” “zero variance”), treat it as a maturity warning sign. A manufacturing reality explainer approach is calmer and more reliable because it respects natural material limits and avoids over-promising.

What “good transparency” sounds like

Good suppliers are comfortable saying: “Here’s what we can control, here’s what we can’t, and here’s how we reduce the probability of failure.” That tone is not defensive—it’s professional.

It also matches how strong B2B-facing manufacturing communication should work: technical truth over marketing language, disclosure before conclusion, and no over-promising on natural materials.

FAQ

If it’s CNC-carved, is it lower quality?

Not automatically. CNC can deliver strong dimensional consistency and repeatability, which is a quality attribute for many B2B programs.

The real quality question is whether the supplier’s process matches the material and the design. For complex jade motifs with variable rough, hybrid workflows are often the professional standard because they manage uncertainty rather than pretending it doesn’t exist.

Can you guarantee every piece looks identical?

In natural stone, that level of guarantee is structurally risky. Even with identical settings, internal micro-cracks, orientation, density, and stress distribution change, and these factors may not be observable before machining.

A credible supplier will commit to an acceptable variation range and explain what is controllable versus what is only mitigable. They should not promise absolute uniformity, zero defects, or identical batches.

Why did a crack appear ‘out of nowhere’ during finishing?

Hidden fractures can exist below the surface without visible signs, and processing stress (including polishing) can expose them. That’s why failures often appear late, and why routine pre-inspection can’t catch everything in practice.

The audit question you should ask is what checkpoints and mitigation actions the factory uses when a new crack is discovered midstream. The strongest suppliers show you their decision logic rather than improvising.

-900x375.webp)