Introduction

Welcome to the official blog of JADE MAGO. As the Editor-in-Chief here, and having spent nearly two decades navigating the dusty, noisy, yet incredibly precise world of gemstone processing and jade manufacturing, I have seen the industry evolve from simple hand-carving to sophisticated CNC machining. Often, when I speak to new retailers or enthusiasts entering the crystal market, I notice a significant gap in knowledge. Most people understand the metaphysical allure or the visual beauty of a stone, but very few understand the mechanical and industrial journey a raw stone takes to become a polished product. This disconnect often leads to misunderstandings about pricing, quality, and authenticity.

At JADE MAGO, we believe that true appreciation—and successful business—starts with understanding the “how.” In this extensive guide, we are going to pull back the curtain on the manufacturing floor. We will move beyond the common marketing fluff to discuss what actually happens during the cutting, grinding, and polishing stages. Whether you are a budding entrepreneur looking to source inventory or a collector wanting to understand why one piece of Rose Quartz costs ten times more than another, understanding Crystal Manufacturing Standards is your most valuable asset. This series will walk you through the eyes of a manufacturer, helping you make informed decisions based on technical reality rather than just aesthetic appeal.

Table of Contents

1: The Raw Reality – Material Selection and Hardness

The very first thing a manufacturer looks at is not just the color of the stone, but its structural integrity and physical properties. Before a single blade touches the stone, we must understand the “Rough”—the industry term for the raw material straight from the mine. For a beginner, the finished product often looks effortless, but the selection of raw material dictates almost 80% of the final quality and price. We have to make calculated decisions on how to orient a stone to maximize its color while minimizing waste, a concept known in our factory as “yield optimization.”

Understanding the Mohs Scale in Production

One of the most critical technical aspects we deal with daily is the Mohs Scale of Mineral Hardness. While many collectors know this scale as a measure of scratch resistance, for us manufacturers, it dictates the entire production line setup. We cannot process a soft stone like Fluorite (Mohs 4) on the same machinery or with the same abrasives used for a harder material like Jadeite (Mohs 6.5-7) or Quartz (Mohs 7). If we were to tumble soft stones with hard stones, the softer materials would be pulverized into dust before the harder ones even achieved a matte finish.

When you are sourcing products, understanding hardness is vital because it correlates directly to “wearability” and “processing difficulty.” Harder stones require diamond-tipped tools and longer processing times, which inherently drives up the manufacturing cost. Conversely, softer stones, while easier to cut, are prone to higher breakage rates during the shaping process. A manufacturer will often charge a premium for intricate carvings made from brittle materials not because the material itself is expensive, but because the risk of the piece snapping during the final polishing stage is incredibly high. For more in-depth scientific data on specific mineral hardness, the Gemological Institute of America (GIA) provides excellent resources that we often reference in our technical training.

The Distinction Between Natural, Treated, and Man-Made

In the current market, the line between “natural” and “fake” is often blurred by a third, very important category: “treated.” From a manufacturing perspective, treating a stone is often a necessary step to make it durable enough for processing. For example, a significant portion of Turquoise and some soft agates are “stabilized.” This means the raw stone is impregnated with a clear resin under high pressure. Without this manufacturing step, the stone would crumble into chalk the moment it hit the grinding wheel.

However, transparency is key. As a buyer, you must learn to ask your supplier about the specific “processing history” of the batch. There is a massive difference between “stabilization” (which preserves the stone) and “dyeing” (which alters the color artificially).

At JADE MAGO, we prioritize educating our clients on these distinctions because they affect the longevity of the product. A dyed stone may fade when exposed to sunlight or react poorly to certain cleaning chemicals, whereas a natural, untreated stone will maintain its integrity.

Beginners should be wary of colors that look too uniform or neon, as nature rarely produces such saturation without imperfections. Resources like Mindat.org are fantastic for verifying if a mineral naturally occurs in the colors vendors are claiming.

Yield Rates and Pricing Logic

Finally, let’s talk about the concept of “Yield.” When we buy a ton of Rose Quartz rough, we do not get a ton of finished products. In fact, depending on the quality of the rough and the complexity of the shape we are cutting, we might lose anywhere from 40% to 70% of the material weight during the grinding and polishing process. This “wastage” is a standard part of the manufacturing equation but is often a shock to new buyers.

If you request a “perfect, inclusion-free” crystal sphere, you are asking the manufacturer to grind away huge portions of the natural stone to isolate the clearest section. This exponentially increases the cost, not just because of the labor, but because of the massive amount of raw material that was sacrificed to create that single flawless piece. Understanding this helps you realize that a higher price tag on a smaller, clearer item isn’t arbitrary; it reflects the sheer volume of material that was discarded to achieve that standard of perfection.

The Transformation – Cutting and Shaping Technologies

Once the raw material has been selected and the yield calculated, the stone enters the most aggressive phase of its lifecycle: the cutting room. For a beginner, this stage is often romanticized as a solitary artisan chipping away with a hammer and chisel. In reality, modern Crystal Manufacturing Standards rely on a sophisticated blend of heavy industrial machinery and high-precision computer-aided design. Understanding the difference between these methods is crucial for buyers, as it explains the consistency—or lack thereof—in the products you receive.

The Mechanics of Slicing and Cooling

The first step in reducing a massive boulder into manageable pieces is slicing, which is performed using large-diameter diamond saws. These are not sharp blades in the traditional sense; rather, they are steel discs impregnated with industrial-grade diamond dust. As the blade spins at thousands of revolutions per minute, it grinds through the stone rather than slicing it. A critical, often overlooked aspect of this process is cooling. Friction generates immense heat that can shatter thermal-sensitive stones like Opal or Obsidian instantly.

Therefore, our factory floors are always wet. We use a constant stream of oil-based or water-based coolants to keep the stone and the blade at a manageable temperature. If you ever purchase a crystal product that has microscopic “crazing” or tiny surface fractures, it is often a sign that the manufacturer rushed the cutting process and allowed the stone to overheat. This is a common defect in low-cost mass production where speed is prioritized over integrity. For those interested in the physics of cutting and thermal shock in minerals, the International Gem Society (IGS) offers detailed articles on lapidary mechanics that explain why temperature control is non-negotiable.

Ultrasonic Carving vs. Hand Carving

One of the most frequent questions we receive at JADE MAGO is, “Is this hand-carved?” In the modern gemstone industry, true hand carving is reserved for high-value artistic pieces due to the immense labor cost involved. The vast majority of standard shapes—such as the popular crystal angels, skulls, or complex geometric pendants—are created using ultrasonic carving machines. This technology uses a metal mold of the desired shape, which vibrates at an ultrasonic frequency against the stone while an abrasive slurry flows between them.

The vibration essentially disintegrates the stone into the shape of the mold. This method ensures that every single piece in a batch of 1,000 is identical in dimension, which is a key requirement for B2B buyers who need standardized inventory. However, beginners should note that ultrasonic carvings often lack the sharp, crisp “undercuts” of hand carving. A hand-carved piece will have deeper details and more fluid lines, reflecting the artist’s individual style. Recognizing the visual difference between a molded product and a carved product will prevent you from overpaying for what is essentially a mass-manufactured item marketed as unique art.

The Rise of CNC in Gemstone Manufacturing

For products requiring geometric perfection, such as massage wands, spheres, or specific jewelry components, we utilize Computer Numerical Control (CNC) machinery. Just as in the metal or wood industries, a CNC machine follows a programmed digital path to grind the stone with extreme precision. This is particularly important for hard stones like Jadeite or Agate where manual grinding would be incredibly slow and prone to human error.

The introduction of CNC technology has elevated Crystal Manufacturing Standards globally, allowing for tighter tolerances in size and shape. When you buy a 10mm bead or a perfectly symmetrical gua sha tool, it is almost certainly the result of CNC processing. This automation allows manufacturers to produce consistent quality at scale, but it also means that the “soul” of the stone is somewhat standardized. As a buyer, knowing whether a product was CNC-machined or hand-shaped helps you gauge whether the price point aligns with the production method used.

The Polish – Where Value is Created

If the cut gives a stone its shape, the polish gives it its life. The difference between a dull, lifeless rock and a glowing gem lies entirely in the polishing process. This is the stage where the surface is refined to reflect light, and it is also where manufacturers can cut corners most easily. A high-quality polish takes time, expensive compounds, and multiple stages. A “commercial polish,” on the other hand, is quick but leaves the surface looking hazy or scratched upon close inspection.

Understanding Grit Progression

Polishing is essentially the act of scratching the stone with finer and finer abrasives until the scratches are too small to be seen by the naked eye. We start with coarse grits, typically around 80 or 100 grit silicon carbide, to remove the deep marks left by the cutting saws. From there, we progress through a standard sequence: 220, 400, 600, 1200, and finally 3000 grit or higher. Each step must completely remove the scratches from the previous step.

If a worker skips a step—say, jumping from 220 directly to 600 to save time—the final stone will have a “bumpy” luster. It might shine, but the reflection will be distorted, and deep underlying scratches will remain visible under strong light. This is a hallmark of “B-grade” manufacturing. At JADE MAGO, we enforce strict adherence to the full grit progression because we know that the final “mirror finish” is what customers associate with premium quality. Organizations likeASTM International set standards for abrasive grain sizes, and reputable abrasive suppliers adhere to these strict charts to ensure consistency in the polishing process.

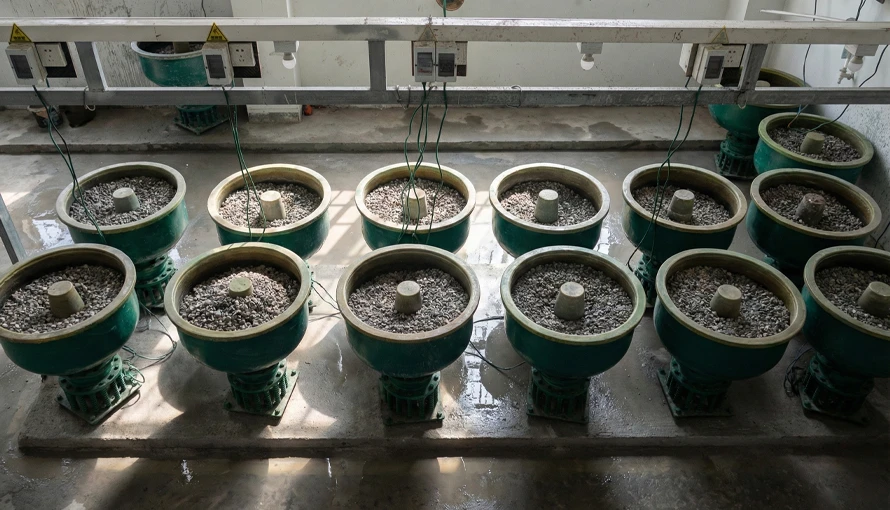

Vibration Polishing (Tumbling) for Mass Production

For smaller items like tumbled stones, chips, or small beads, we cannot polish them individually by hand. Instead, we use large vibrating tumblers. These machines are filled with hundreds of pounds of stones, ceramic media, and abrasive grit. They vibrate or rotate for days or even weeks at a time. This process replicates the natural erosion of a riverbed but at a highly accelerated rate.

The key variable here is time. A cheap tumbled stone might be processed for only 3 days, resulting in a matte or semi-gloss finish with pitted surfaces. A premium tumbled stone might be in the barrels for 4 to 6 weeks, undergoing multiple grit changes and thorough washing in between. The result is a stone that feels like glass and has no remaining pits or cracks. When you see a significant price difference between two vendors selling “tumbled rose quartz,” the difference is almost always in the duration of the tumbling cycle and the cost of the electricity and abrasives consumed during those extra weeks.

Chemical Treatments and Waxing

It is an open secret in the industry that the final step of polishing often involves a bit of chemistry. Many stones, especially those with micro-fissures like Rose Quartz or Emerald, are subjected to a final “waxing” or “oiling.” This involves dipping the finished stone into a warm paraffin wax or specialized oil. The wax fills in microscopic surface imperfections and improves the stone’s luster.

While this is a generally accepted practice for certain minerals, it becomes an issue when it is used to hide poor polishing work. A heavily waxed stone will look amazing when you first unpack it, but after a few weeks of handling, the wax will wear off, revealing a duller surface underneath. As a discerning buyer, you can sometimes test for this by feeling the stone; a heavily waxed stone will have a slightly greasy or “warm” feel compared to the cold, dry feel of a natural polish. We believe in minimal intervention—using polish to achieve the shine, not wax to fake it.

The Final Gate – Quality Control and Defect Recognition

After the polishing and waxing stages are complete, every batch of stones must pass through Quality Control (QC). In a reputable factory like JADE MAGO, this is the most rigorous stage of the entire operation. For a beginner, distinguishing between a “natural characteristic” and a “manufacturing defect” can be incredibly difficult. However, understanding this distinction is the single most important skill you can develop to avoid purchasing sub-par inventory.

Distinguishing Cracks from Inclusions

The most common dispute between manufacturers and buyers revolves around the definition of a crack. Crystals are natural materials, and they almost always contain internal structures called inclusions. These can be veils, clouds, or other mineral deposits trapped inside the stone during its formation millions of years ago. In the world of Crystal Manufacturing Standards, inclusions are acceptable and often desirable as proof of natural origin. A crack, however, is a structural failure.

A “crack” usually occurs because of thermal shock during cutting or physical impact during shipping. The professional way to distinguish the two is the “fingernail test.”

If you run your fingernail across the surface of the stone and it catches on the line, it is a surface fracture or a crack. This is a manufacturing defect because it weakens the stone’s integrity. Conversely, if your fingernail glides smoothly over the line, it is likely an internal inclusion, which is structurally sound.

We train our QC staff to reject any stone where a fracture breaks the surface plane, as these stones are liable to snap in the future. For detailed visual guides on inclusions, the Gemmological Association of Great Britain (Gem-A) offers resources that help identify internal features versus external damage.

Drilling Precision and Alignment

For those of you purchasing beads, pendants, or any component intended for jewelry making, the quality of the drill hole is a tell-tale sign of the factory’s capability. Drilling stone is technically difficult because the drill bit generates immense localized heat. If the manufacturer rushes this process, the heat will cause “blowouts” or chipping around the exit hole.

A high-quality bead is drilled from both sides meeting in the middle, rather than drilled straight through from one side to the other. This double-sided technique prevents the stone from chipping when the drill bit exits. When you inspect your inventory, look closely at the holes. If you see jagged edges or if the hole is significantly off-center, it indicates that the manufacturer is using outdated equipment or unskilled labor. Misaligned holes make it impossible for jewelry designers to create straight, hanging pieces, effectively rendering the product useless for high-end applications.

5: The Human Element – Ethics and Safety in Manufacturing

As we conclude this deep dive into the industry, we must address the environment in which these products are made. The crystal industry has faced scrutiny regarding labor conditions, and as a manufacturer, I believe transparency is the only way forward. When you buy a product, you are supporting the entire supply chain behind it, including the safety protocols on the factory floor.

Silicosis Prevention and Worker Safety

The processing of quartz and other silica-based minerals creates fine dust that is extremely hazardous if inhaled. This can lead to a condition known as silicosis, a serious lung disease. Therefore, a responsible manufacturer never grinds stone “dry.” Wet grinding—where water constantly suppresses the dust—is the absolute minimum safety standard. Furthermore, modern factories utilize high-powered air filtration systems and require workers to wear N95 or respirator masks.

When you are vetting a new supplier, ask them about their dust management systems. A factory that cannot answer questions about silicosis prevention is likely cutting corners on worker safety to lower costs. Supporting manufacturers who invest in health and safety ensures that the industry remains sustainable and humane. The Occupational Safety and Health Administration (OSHA) provides global benchmarks for silica exposure that compliant international factories strive to meet.

Sourcing Integrity and “Conflict-Free” Minerals

Beyond the factory floor, the origin of the rough material matters. Just as with diamonds, the colored stone industry is moving toward greater traceability. While it is difficult to trace every single tumble stone back to a specific artisanal mine, large manufacturers have the purchasing power to demand ethical sourcing documentation from mines.

We focus on sourcing from regions with established mining regulations to ensure that no child labor or conflict financing is involved in the extraction process. By consolidating our purchasing and building long-term relationships with specific mine owners, we can better guarantee the ethical status of our raw materials. As a retailer, you can pass this assurance on to your customers, adding significant value and trust to your brand story.

Conclusion: Empowering Your Business with Knowledge

The journey of a crystal from a rough, dusty boulder to a polished, glowing product is a feat of engineering, chemistry, and artistry. By understanding the rigorous Crystal Manufacturing Standards—from the Mohs hardness of the raw material to the precision of the CNC cut and the integrity of the final polish—you are no longer just a passive buyer. You are an informed partner.

At JADE MAGO, we have spent years refining these processes because we know that quality is not an accident; it is the result of intelligent effort. We hope this guide has demystified the manufacturing world for you. Whether you are launching a new e-commerce store or looking to upgrade your existing supply chain, remember that asking technical questions is your right. Look for the polish quality, test for the cracks, and ask about the yield.

Your customers rely on you to curate the best the earth has to offer. Now, equipped with the knowledge of what happens behind the factory doors, you are ready to make choices that build a reputation for excellence. If you have further questions about custom processing or need specific technical advice for your next product line, the JADE MAGO team is always here to bridge the gap between the raw stone and the retail shelf.

Frequently Asked Questions

What is the difference between “Stabilized” and “Dyed” stones?

Stabilization: A necessary process where raw stone (like Turquoise) is impregnated with resin to make it durable enough to be cut and shaped without crumbling. This preserves the stone.

Dyeing: Artificially altering the stone’s color.

Note: Buyers should always ask for the “processing history” to ensure transparency.

Is my crystal product hand-carved?

Likely not, unless it is a high-value artistic piece.

Ultrasonic Carving: Most standard shapes (angels, skulls) are made using ultrasonic machines and molds to ensure identical dimensions for mass production.

CNC Machining: Used for geometric perfection (beads, massage tools) to achieve tight tolerances that hand-grinding cannot match.

Hand Carving: Reserved for unique, high-labor pieces and features deeper details and undercuts.

Is waxing or oiling stones acceptable?

It is a common practice for stones with micro-fissures (like Rose Quartz) to improve luster. However, it becomes an issue if used to hide poor polishing. If a stone looks dull after a few weeks, the wax has likely worn off, revealing a sub-par finish.

-900x375.webp)