Introduction

For B2B manufacturing, the raw material supply chain determines two critical outcomes: your profit margin and your product consistency. In the jade and semi-precious stone industry, a fractured supply chain is the primary cause of production delays and quality variance.

At JADE MAGO, we reject the traditional multi-broker model. Instead, we utilize a Direct Rough Stone Procurement strategy. This is not merely a purchasing preference; it is a calculated operational framework designed to secure high-yield materials at mine-gate prices. By eliminating intermediaries, we provide our clients with a 30% to 40% cost advantage and full traceability. This article details the technical mechanics of our sourcing protocol and how it safeguards your business interests.

Table of Contents

Economic Implications of Direct Sourcing

To understand the economic benefits of direct sourcing, we must first analyze the costs structure of traditional markets. Traditional jade supply chains rely on inefficient transactions which add no real value.

Deconstructing the “Broker Tax”

On average, rough stone passes hands four to six times before arriving at its final destination – often via intermediaries such as brokers.

Mine Owner: Extracting Stone. Financier: Purchase Bulk Raw Material At Pit

Factory: Purchases the material at a significantly marked-up rate. Our procurement department estimates that each layer adds between 15% and 25% markup; by the time a factory purchases its stone, its price per kilogram has often skyrocketed by 70% over mine gate price. At JADE MAGO, we take an innovative approach by dispatching our own buyers directly to extraction sites, thus eliminating middlemen from this chain; instead committing more budget to more advanced processing technology than paying middlemen.

Data-Driven Cost Stability

Price volatility is one of the primary risks in B2B contracts. Stone prices fluctuate weekly due to speculative trading activity in open markets, making it impossible to lock in annual pricing agreements for your retail partners.

Our direct sourcing model helps mitigate these costs. We negotiate seasonal volume contracts directly with mining cooperatives.

Fixed Pricing: Our raw material rates are locked-in for 6-month cycles with fixed pricing and volume discounts (we buy 5 to 10 tons at once to secure better rates than smaller traders can access), providing you with a more predictable “Cost of Goods Sold” (COGS) that helps safeguard long-term margins.

JADE MAGO Procurement Protocol

Our purchasing decisions do not rely on intuition alone; rather, we rely on the JADE MAGO Procurement Protocol (JMPP), an industry standard methodology for evaluating raw materials. This framework ensures that every stone that enters our warehouse meets stringent manufacturing criteria.

Geological Origin Verification

Alitat Different mine pits produce stones with distinct physical characteristics. For example, jadeite from Myanmar’s Hpakan region differs significantly in density and hardness from material mined in Guatemala.

Verification: Our on-site geologists perform verification for each “vein” or pit origin

Documentation: When extracting stones, we keep records of their extraction date and coordinates. Keeping this data helps us predict how each stone will respond when subjected to CNC carving and polishing processes, selecting appropriate abrasives from its origin to prevent microcracks during production.

The “Windowing” Assessment Technique

Buying “blind” stones (those without full skin coverage) can be seen as gambling with client capital, which is why we require our “Windowing” process for all high-value purchases.

Cut: We create a small incision into the rough stone’s skin.

Light Test: High-lumen focused torches (3000K and 6000K light sources) penetrate this window, testing for color saturation and impurity levels hidden underneath its weathered surface. Analysis: Our tests expose “Meat”, or the actual colors saturation levels and impurity levels hidden underneath its weathered exterior surface.

This step drastically lowers your risk of buying “dead stones”, or boulders which appear promising but contain gray inclusions or fractures on closer examination.

Technical Quality Metrics & Yield Prediction

Quality is the result of hard science, not art. At our facility in China, we use quantitative metrics to assess rough stones. This ensures the material matches your specific product needs – whether that means high-end jewelry or mass market massage tools.

Hardness and Density Testing

Prior to shipment, a sample from each batch is tested using portable gemological instruments for hardness and density testing.

Mohs Hardness (e.g. 6.5-7.0 for Jadeite and Quartz respectively). Softer stones tend to polish poorly and scratch easily in consumer use. Specific Gravity (Density): We utilize hydrostatic weighing to measure density – standard standards require Jadeite exceed 3.30g/cm3.

Deviation: Any result below 3.28 g/cm3 indicates low-grade stone or composite fake and will be immediately rejected by us. Yield Prediction Analysis (YPA)

Cost control can best be managed using Yield Rate; which measures how much usable material was extracted from each raw boulder.

Industry Average: Yield rates for rough jade can often range between 15%-20% due to internal cracks. Our experts use Yield Prediction Analysis; mapping surface fissures into its 3D volume.

Threshold: At our mines, we only purchase boulders with yield estimates exceeding 30%. By filtering out low yield stones at the mine, we avoid paying freight charges for waste material – reducing per-unit costs significantly and providing substantial savings for B2B clients ordering 10,000 units or more at once. A 10% increase in material yield could lead to substantial savings off their final invoices.

Strategic Inventory and Supply Continuity

Relying solely on just-in-time purchasing for raw stones can be risky; weather, politics and logistics could easily disrupt our supply. Instead, we employ our proprietary Strategic Buffer Model.

Mitigating Seasonal Disruptions Mining operations in Southeast Asia and Africa are dependent upon monsoon seasons from June through September; during this time period mines close and supply decreases significantly.

Problem: Competitors who purchase spot inventory face shortages or price spikes during the rainy season. Our Solution: We execute bulk purchasing during Q1 and Q4 of every year (the dry seasons).

Data Point: At Stonecrafter we maintain an inventory of over 50 tons of rough stone across various categories (Jade, Rose Quartz and Amethyst) to help ensure year-round production lines run efficiently regardless of conditions at your mine site. This cushion ensures your production lines continue to run without issues throughout their year-long operation.

Vertical Integration: From Boulder to Finished Product

Many factories operate as assembly-only workshops; once your order has been placed, they then purchase pre-cut stone slabs – this creates delays and limits design flexibility. At JADE MAGO, however, our direct ownership of rough stones allows for Vertical Integration; our experience bridges geology and engineering.

Custom Cutting Capabilities

Most factories only stock standard slab sizes. If you require something with unique dimensions – like a large crystal bowl or extra thick jade bracelet – their pre-cut materials cannot meet this demand and they may deny your order altogether.

As our raw boulder inventory ranges from 10kg to 500kg, we are not restricted by market standards.

Geometric Freedom: We cut stone specifically to your design.

Example: For one of our recent clients who needed custom-shaped Gua Sha tools, we programmed our wire saws to slice at 45-degree angles so as to optimize structural strength of each stone piece.

Results: With this tailored approach to shipping, they were able to reduce breakage by 15% when compared with their prior supplier who used standard flat slabs.

Speed to Production (Lead Time Reduction) In traditional supply chains, the “Procurement Phase” may take 2 – 4 weeks. A factory must negotiate, wait for delivery and inspect each stone; if its quality fails inspection, the cycle continues.

With our direct sourcing model, the “Procurement Phase” is effectively nonexistent.

Order Confirmation: Once approved, we move pallets of rough stone from our on-site warehouse directly onto the cutting floor within four hours for immediate distribution.

Time Savings: Our production lead times typically decrease by 14-20 days compared to traditional production models, giving your retail launches (like Valentine’s Day or Christmas) an invaluable competitive edge.

Ethical Sourcing and Corporate Social Responsibility (CSR)

Modern consumers demand transparency; they want assurances that their products don’t contribute to human rights violations or environmental degradation. B2B buyers view supply chain ethics as part of maintaining brand image and legal compliance.

Conflict-Free Verification

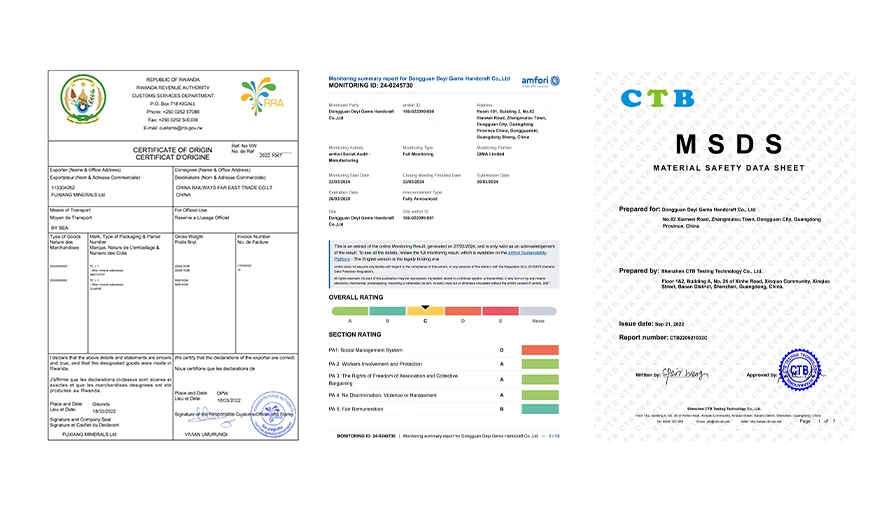

Mining industry labor conditions have historically presented their own set of difficulties. We strictly abide by a Zero Tolerance Policy when it comes to illegal labor practices, while screening our mining partners against international standards.

No Child Labor: Our site visits ensure that all workers are adults of legal working age and all requirements for safety standards (helmets, boots, ventilation) have been fulfilled by partner cooperatives.

Audit Trail: For materials destined for retail in stringent markets such as Europe or North America, we can provide affidavits of origin that adhere to OECD Due Diligence Guidance guidelines. Such documentation is vital when retailing.

Environment Stewardship & Waste Management

Stone extraction can be environmentally damaging. Our commitment to Responsible Mining requires us to source from licensed operations which legally oblige them to rehabilitate the land after closing pits (replanting vegetation).

Additionally, our factory practices Total Resource Utilization.

Primary Cut: High-grade meat is reserved for premium orders (such as jewelry and carvings).

Secondary Cuts are then utilized for smaller items (e.g. beads and phone charms). Tertiary Uses include ground down scraps being ground into mosaic tiles for mosaic designs.

Impact: By recycling waste for energy production, this action reduces landfill waste while respecting natural resource limits.

Quality Assurance (QA) Firewall

Securing good stone is only half of the battle. Ensuring it lasts through manufacturing requires an efficient Quality Assurance framework; we utilize 100% Inspection Protocol at key stages instead.

Our “Three-Gate” Inspection System

To ensure quality is constantly monitored and tested at each gate, if a product fails any gate it is immediately rejected and must not enter further production.

Gate 1: Rough Slice Inspection: After the first cut is complete, we inspect the slab wet for any hidden cracks that were not initially visible in the boulder. If any are found, they are marked using red wax pencil in order to assist the CNC operator in working around any defects that might exist.

Gate 2: Semi-Finished Form (Pre-Polish): After carving but prior to polishing, we assess its shape accuracy. Metric: Dimensions are checked against your technical drawing (with tolerance allowance of +-0.5mm). Action: Any imperfections are either reground or recycled for reuse.

Gate 3: Final Aesthetic Check: Completed products are evaluated under standard 5000K lighting for aesthetic imperfections such as surface scratches, polish consistency and color uniformity. Our inspectors look out for surface scratches, polish consistency and color uniformity to determine their aesthetic value.

Rejection Rate: Our aim for an internal rejection rate of less than three percent in this stage, so what ships to you is near-perfect. Traceability and Batch Coding (BCN) For larger B2B orders, we assign a Batch Control Number that links your finished boxes back to the lot of rough stone used.

Accountability: When customers experience issues months later, we can trace back their BCN to identify exactly which raw material batch was used and correct for it accordingly – something which traders cannot provide.

Conclusion

In the B2B jade and gemstone industry, quality control rests with those with direct control of the source. Relying on middlemen to access jade or gemstone suppliers is outdated, expensive, and risky as it leaves your brand vulnerable to price spikes, inconsistent quality standards, ethical blind spots, etc.

JADE MAGO’s Direct Rough Stone Sourcing model was specifically created to address modern business needs.

By eliminating brokers, we reduce costs while guaranteeing quality by selecting stones using geological knowledge.

We ensure your timeline by maintaining strategic inventory buffers. By working with us, you not only purchase products; you become part of a reliable supply chain engineered for growth. Let us show you the difference that professional, direct sourcing can make.at professional, direct sourcing makes.

Frequently Asked Questions

Can I verify the authenticity of the rough stone used for my order?

Yes. Because we own the material, we offer full traceability. For large volume orders, we can provide:

1.Origin Documentation: Verification of the specific mine or region.

2.Raw Sample Inspection: We can ship a sample of the raw cut off-cut along with your finished goods.

3.Lab Certification: Upon request, we can facilitate third-party gemological testing (NGTC or GIA standards) on the raw batch before mass production begins.

How does Direct Sourcing save me money if you don’t buy “cheap” stone?

We save you money on the Transaction, not by degrading the Material. In a traditional model, a stone passes through 5 hands, with each broker adding 20%. You end up paying $100 for a stone that is only worth $40. With JADE MAGO, you pay $50 for a stone that is worth $50. You pay less in total, but you actually receive a higher value of raw material. This results in a finished product that looks significantly more expensive than its production cost, giving you better margins at retail.

Why can’t I find rough jade at “rock bottom” prices?

In the legitimate stone industry, there is a “Mining Cost Floor.” While we cut out middleman markups, the base cost of extraction—fuel, heavy machinery, labor, and government mining taxes—is fixed. If a supplier offers rough stone significantly below this global market floor, it is a red flag. It typically indicates one of three things:

1.Treated Material (B/C Grade): The stone has been acid-washed and resin-filled to hide defects.

2.Illegal Extraction: The material was stolen or mined without permits, posing legal risks for your supply chain.

3.Low Yield: The stone is mostly “waste rock” with very little usable meat. At JADE MAGO, we price competitively based on efficiency, but we never price below the cost of ethical extraction.

-900x375.webp)