Introduction

Can you feel the difference between a $20,000 piece of jade and a $200 crystal? Most people in the jade and gemstone industry would tell you “absolutely”—and they’d point to the material cost, the rarity of the stone, or the complexity of the carving. But here’s what they won’t tell you: in most manufacturing facilities, the actual processing standards applied to these two pieces are drastically different. The $20,000 jade gets the master craftsman’s attention, precision equipment, and meticulous quality control. The $200 crystal? It often gets whatever’s left over.

This isn’t just an industry quirk—it’s a systemic problem that affects everyone from small Etsy sellers to major cross-border e-commerce brands. If you’re sourcing jade products for your business, you’ve probably experienced this firsthand. Beautiful samples that somehow don’t translate to consistent production quality. Entry-level products that feel noticeably cheaper than your premium lines. Customer reviews that mention “quality control issues” on your more affordable items while praising your luxury pieces.

The question isn’t really whether there should be a difference in jade processing based on material cost. The real question is: should your customers receive different levels of craftsmanship based on how much they can afford to spend? At Jade Mago, we believe the answer is definitively no. After more than six decades specializing exclusively in jade and crystal processing, we’ve built our entire operation on a principle that many in the industry consider radical: production standards should never be negotiable, regardless of the material’s price tag.

In this article, we’ll explore why most jade processors use tiered production systems, what this means for your business and your customers, and why adopting uniform processing standards across all price points isn’t just ethical—it’s the smartest business decision you can make.

Table of Contents

The Industry’s Dirty Secret: Tiered Production Standards

How Most Jade Processors Really Operate

Walk into most jade processing facilities, and you’ll notice something immediately: there’s an invisible hierarchy that determines which craftspeople touch which materials, which equipment gets used for which orders, and how much time gets allocated to each piece. This tiered production system has become so normalized in the industry that many manufacturers don’t even try to hide it anymore.

Here’s how it typically works. When a high-value material arrives—let’s say a premium nephrite jade worth $15,000—it gets assigned to the facility’s most experienced craftspeople, often masters with 20 or 30 years of specialized experience. The piece goes through CAD modeling for precision planning, gets processed on the newest CNC equipment, and passes through multiple quality control checkpoints. Every step receives careful attention because the material cost alone demands it.

The Treatment Your Lower-Priced Orders Actually Receive

Now contrast that with what happens when a $200 quartz crystal or lower-grade jade piece enters the same facility. These pieces often get batch-processed with minimal individual attention. They might be assigned to apprentice-level craftspeople who are still learning the trade. The equipment used might be older models that can’t achieve the same precision tolerances. Quality control checkpoints get condensed or skipped entirely because “it’s just a $200 piece—nobody will notice.”

According to research published by the Gemological Institute of America, inconsistency in gemstone processing is one of the leading causes of customer dissatisfaction in the jewelry and lapidary industry. Yet the practice continues because it seems to make economic sense on the surface. Why invest the same resources in a $200 piece that you’d invest in a $20,000 piece?

Why This Creates Problems You Can’t Ignore

The answer becomes clear when you look at it from your customer’s perspective. They don’t know what the raw material cost. They don’t know that you paid $50 for the quartz versus $5,000 for the jade. What they know is that they purchased a product from your brand, and they have certain expectations about what that brand represents. When the craftsmanship quality varies dramatically across your product line, customers notice—even if they can’t articulate exactly what feels “off.”

This creates a cascade of problems for businesses at every level. Small sellers and individual studio owners find themselves unable to compete because they can’t guarantee quality across their entire catalog. Enterprise product managers face endless quality control nightmares trying to manage multiple SKUs with inconsistent production standards. And everyone loses customers who bought an entry-level product, had a mediocre experience, and never came back to try the premium offerings.

The Real Cost of Inconsistent Processing Standards

What Happens to Your Brand When Quality Varies

Brand damage doesn’t happen all at once—it accumulates slowly, like water wearing down stone. One customer receives a $200 crystal that feels cheap and poorly finished. They don’t write a review or complain; they simply never buy from you again. Another customer gifts one of your affordable pieces to a friend. The friend notices the rough edges, the uneven polish, the lack of attention to detail. They don’t say anything to avoid seeming ungrateful, but they definitely don’t become a customer themselves.

Then, inevitably, someone does leave a review. In today’s connected marketplace, a single detailed negative review about quality issues can undo months or years of reputation building. According to research from Northwestern University, customers trust online reviews almost as much as personal recommendations, and negative reviews have a disproportionate impact on purchasing decisions.

The Hidden Emotional Toll on Your Customers

Beyond the business metrics, there’s a human cost to inconsistent jade processing standards that we don’t talk about enough. Consider the person who’s been saving for months to buy their first piece of genuine jade—a $200 pendant that represents a significant investment for them. They’ve read about jade’s cultural significance, its connection to protection and good fortune. They’re excited to finally own a real piece.

When that pendant arrives and the quality doesn’t match their expectations, it’s not just disappointment—it’s a form of betrayal. They trusted your brand to deliver something meaningful, and instead, they received something that feels mass-produced and careless. Maybe the carving lacks the crispness they saw in your photos. Maybe the polish has subtle imperfections that catch the light wrong. These might seem like small details to a manufacturer focused on profit margins, but to that customer, it diminishes what should have been a special moment.

The Perpetuation of Inequality Through Craftsmanship

There’s also a philosophical problem here that extends beyond individual transactions. When the jade industry accepts tiered production standards as normal, we’re essentially saying that craftsmanship and respect are luxuries reserved for wealthy customers. The person who can afford a $20,000 jade sculpture gets to experience masterful artistry, while someone purchasing a $200 crystal gets “good enough.”

This perpetuates a troubling message: your worth as a customer is determined by how much you can spend. In an industry that works with materials historically associated with spiritual significance, harmony, and balance, this feels particularly wrong. As the International Gem Society notes in their ethics guidelines, quality craftsmanship should be a baseline standard, not a premium feature.

Understanding What True Quality Standards Look Like

The Seven Critical Stages Every Piece Should Pass

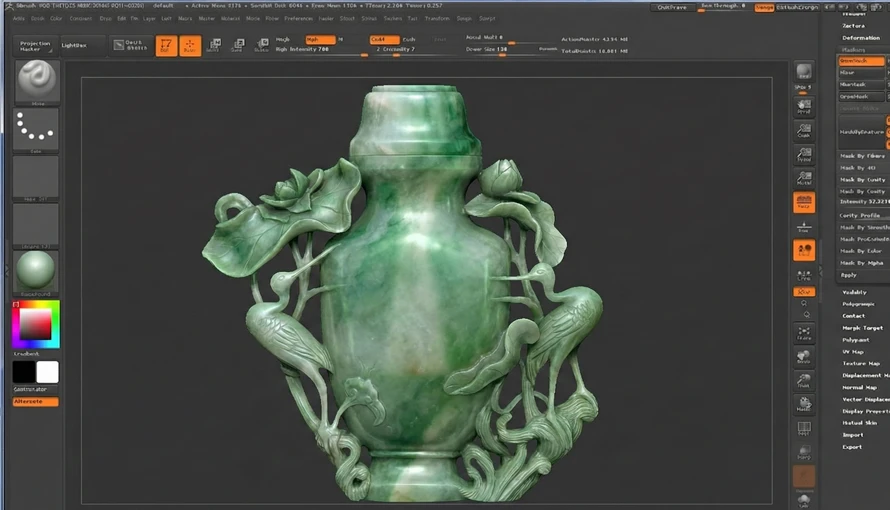

When we talk about consistent jade processing standards at Jade Mago, we’re not talking about vague commitments or marketing language. We’re talking about specific, measurable procedures that every piece passes through regardless of material cost. Let me walk you through what this actually looks like in practice.

The first stage is material assessment and planning. Whether we’re working with a $20,000 piece of imperial jade or a $200 rose quartz crystal, every material gets the same detailed evaluation. We examine the internal structure, identify any potential weaknesses or inclusions, and create a processing plan that respects the unique characteristics of that specific piece. This happens before any cutting begins.

CAD Precision Modeling: Not Just for Premium Pieces

Stage two involves CAD precision modeling. Many facilities reserve this step for expensive materials only, reasoning that computer-aided design is overkill for affordable items. We disagree fundamentally. The digital modeling stage is where we ensure that the final piece will have proper proportions, balanced weight distribution, and optimal use of the material. Skipping this step for lower-priced items is exactly how you end up with pieces that look “off” even if customers can’t pinpoint why.

Our master craftspeople—each with a minimum of ten years specialized experience—handle the actual processing in stage three. Notice I didn’t say “our master craftspeople handle the expensive pieces while apprentices handle the cheap ones.” Material cost doesn’t determine craftsperson assignment in our facility. The person carving a $200 piece has the same skill level and experience as the person working on a $20,000 piece. They might even be the same person, moving from one project to another based on workflow rather than material hierarchy.

Where Most Facilities Cut Corners (And We Don’t)

Stages four and five are where many facilities really start cutting corners with affordable materials: detailed hand-finishing and multi-stage polishing. We use the same polishing compounds and equipment across all price points. A rose quartz getting its final polish receives the same attention and materials as a high-grade nephrite jade. This is non-negotiable because the polish is often what customers notice first—it’s literally how the piece meets the world.

Quality control inspection forms stage six, and this is perhaps where the industry’s tiered approach is most damaging. In facilities using separate standards for different price points, expensive pieces might pass through five or six inspection checkpoints while affordable pieces get a single cursory glance. At Jade Mago, every piece passes through seven distinct quality checkpoints regardless of value. Each checkpoint has specific criteria that must be met before the piece advances.

The final stage is packaging and documentation. Even here, standards matter. The same protective packaging, the same handling protocols, the same care in preparation for shipping applies whether we’re sending out a $200 order or a $20,000 order. Your customer’s unboxing experience should reflect your brand values, not the wholesale cost of the material.

Why Jade Mago Chose a Different Path

The Philosophy Behind Uniform Standards

More than sixty years ago, when Jade Mago was founded, our founders made a choice that would define everything we’d become. They’d both worked in facilities where production standards varied based on material cost, and they’d seen the consequences—not just for businesses, but for the individual customers who received those inconsistently crafted pieces. They decided to build a company based on a simple but radical premise: craftsmanship should be a baseline, not a luxury feature.

This wasn’t purely altruistic. They recognized something that many in the industry still miss: inconsistent quality is actually more expensive in the long run. When you maintain different production standards for different price points, you need separate workflows, different training protocols, multiple quality control systems. You need to constantly make judgment calls about which pieces deserve which level of care. This creates complexity, increases error rates, and makes it nearly impossible to achieve true operational excellence.

What Happens When We Turn Down Profit

I’ll be honest with you: we’ve turned down projects because potential clients asked us to “simplify processes for cheaper items.” These are real conversations we’ve had. A brand wants us to manufacture their product line—premium pieces and affordable pieces—but they explicitly request different production standards for different tiers. They frame it as “efficiency” or “matching quality to price point.”

We say no to these projects, even though it costs us revenue. Why? Because once you start making exceptions, you’ve fundamentally changed what your company stands for. You’re no longer a manufacturer with unwavering standards; you’re a manufacturer with flexible standards that adjust based on commercial pressure. That’s not who we are, and it’s not who we can become while maintaining integrity.

The Measurable Results of Non-Negotiable Standards

The decision to maintain uniform processing standards across all price points has given us results that speak louder than any marketing claim. Our quality acceptance rate stands at 99.3% across all price tiers. Think about what that means: whether a client orders $200 crystals or $20,000 jade carvings, they accept 99.3% of what we produce without requesting remakes or refunds. This isn’t because we’re lucky or because our clients aren’t discerning—it’s because consistent standards produce consistent results.

Our return rate tells an even more compelling story. While the industry average for product returns hovers between 3-5% according to data from the Jewelers of America, our return rate is under 0.5%. These aren’t just numbers on a spreadsheet—each percentage point represents real customers who received exactly what they expected, who felt respected by the quality they received, and who’ll likely become repeat buyers.

We’ve worked with over 500 partners ranging from solo Etsy sellers to major cross-border e-commerce brands. The small sellers tell us that our consistent quality lets them compete with bigger brands despite having smaller budgets. The enterprise clients tell us that we’re the only manufacturer where they can confidently expand their product line without worrying that quality will slip as they move into more affordable price points.

What Inconsistent Standards Really Cost Your Business

The Customer Lifetime Value You’re Losing

Let’s talk about a metric that many businesses overlook when evaluating their manufacturing partners: customer lifetime value. When someone buys an entry-level product from your brand—maybe a $200 crystal pendant—they’re not just making a single $200 purchase. They’re potentially beginning a relationship with your brand that could be worth thousands of dollars over time.

But here’s what happens when that first purchase doesn’t meet their expectations because it received inferior processing treatment. They don’t just fail to make a second purchase; they become actively resistant to your brand. They’ve been burned once, and they’re not coming back. You’ve permanently lost not just the $200 they spent, but the $2,000 or $20,000 they might have spent over the following years as they became more interested in jade and moved up to premium pieces.

The Operational Chaos of Managing Multiple Standards

There’s also the internal cost of maintaining different production standards for different price points—costs that are often invisible until you experience the alternative. Your team needs to constantly make decisions about which standard applies to which product. Quality control personnel need different checklists for different tiers. Customer service deals with confusion when defects that would be unacceptable in premium pieces are deemed “acceptable given the price point” in affordable items.

This creates a culture of rationalization rather than excellence. Instead of asking “does this meet our standards,” your team starts asking “does this meet the standards for this particular price tier?” The psychological shift is subtle but corrosive. You’re teaching your organization that quality is negotiable, that corners can be cut if the justification is right. That mindset inevitably bleeds into other areas of your business.

When One Bad Product Destroys Years of Brand Building

In the age of social media and instant global communication, a single quality failure can have outsized consequences. Imagine you’ve spent three years building a brand reputation for quality jade products. Your premium pieces get rave reviews. Customers tag you on Instagram showing off their purchases. You’ve worked hard to position yourself as a trustworthy source in a market filled with questionable sellers.

Then someone buys one of your affordable pieces—a piece that received inferior processing because your manufacturer uses tiered production standards. The carving is sloppy. The polish has visible imperfections. Maybe there’s even a small crack that developed because the material assessment wasn’t thorough. That customer posts a detailed review or social media video documenting the quality issues. The video goes semi-viral in the jade and crystal community.

Suddenly, you’re not the quality brand anymore. You’re the brand that delivers inconsistent quality. People start questioning whether your premium pieces are actually as good as claimed, or whether those rave reviews are somehow manipulated. Three years of reputation building undermined by one piece that didn’t receive proper processing standards. Was saving $30 on manufacturing costs really worth that risk?

The Jade Mago Approach: How We Ensure Consistency

Starting with Transparency in Our Discovery Process

When a potential partner first contacts Jade Mago, we begin with a discovery conversation that might surprise them. We don’t immediately talk about minimum order quantities or rush delivery fees. Instead, we ask about their vision for their product line, their target customers, and what they want their brand to represent. We ask about their price points too—but not so we can tier our services accordingly.

We share our production specifications upfront, making it clear that these same specifications will apply whether they’re ordering $200 items or $20,000 pieces. Some potential partners are surprised by this. They’ve worked with other manufacturers where the conversation begins with “what’s your budget” and the proposed quality level adjusts accordingly. Our conversation starts with “what standards matter to you” and then we explain that those are the standards every piece will meet.

Why Our Sample Quality IS Our Production Quality

This is where we differ most dramatically from typical manufacturing processes. In many facilities, samples receive special treatment. They’re handled by the best craftspeople, get extra quality checks, and generally receive a level of care that won’t be replicated in mass production. This creates a bait-and-switch dynamic where brands approve samples thinking that’s the quality they’ll receive, only to discover that production pieces don’t quite measure up.

At Jade Mago, we produce samples using exactly the same workflow, craftspeople, equipment, and quality standards that will be used for production. When you approve a sample, you’re not approving an aspirational version of what your product might be—you’re approving exactly what your production pieces will look like. This eliminates the most common source of disappointment and conflict in manufacturer-client relationships.

We document our seven-stage quality process and share it with partners during the sample phase. You’ll see detailed notes from each checkpoint, photographs showing the piece at different stages, and even information about which specific craftsperson handled which aspect of the work. This level of transparency might seem excessive, but it builds trust that proves invaluable during production scaling.

Real-Time Visibility Throughout Production

Once production begins, we maintain communication that many of our partners tell us is unusual in the manufacturing world. You receive real-time updates at each major stage, not just when there’s a problem. We share quality reports that use the same criteria and checkpoints as your approved samples. If we identify any material irregularities or processing challenges, you hear about them immediately along with our proposed solutions.

This isn’t just good customer service—it’s a natural outgrowth of maintaining consistent standards. When you have clearly defined, non-negotiable quality criteria, it becomes straightforward to report on them. There’s no ambiguity about whether something meets standards or not. There’s no need to make excuses or rationalize why a particular piece doesn’t quite measure up “given the price point.” It either meets our standards or it doesn’t ship.

Making the Case for Uniform Standards to Your Team

How to Calculate the True Cost of Inconsistency

If you’re in a position where you need to justify changing manufacturers to partners or executives focused on bottom-line costs, here’s how to frame the conversation. First, calculate your current return and remake costs. How much are you spending annually on replacing defective products? How much staff time goes into processing returns and managing customer complaints about quality issues?

Next, estimate the customer lifetime value you’re losing. If your typical customer should theoretically make 3-4 purchases over two years, but your actual repeat purchase rate is significantly lower, that gap represents lost revenue directly attributable to quality inconsistency. Industry research from Harvard Business Review suggests that acquiring a new customer costs 5-25 times more than retaining an existing one, making customer lifetime value calculations particularly important.

The Competitive Advantage of Reliable Quality

Then there’s the competitive positioning benefit. In a market where most jade sellers struggle with quality consistency, being able to confidently promise “our $200 pieces receive the same craftsmanship as our $2,000 pieces” becomes a powerful differentiator. This isn’t just marketing talk when you have a manufacturing partner whose processes actually support that claim—it’s a verifiable competitive advantage.

You can also market more authentically. Instead of vague claims about “commitment to quality,” you can tell the specific story of your manufacturing partnership. You can explain the seven-stage quality process every piece passes through. You can share your industry-leading acceptance rates and minimal return rates. Specificity builds trust in ways that generic quality claims never can.

What Your Customers Deserve (And Will Pay For)

Finally, there’s the fundamental ethical argument that often resonates more than people expect. Your customers—regardless of whether they’re buying affordable entry-level pieces or premium investment pieces—deserve respect. They deserve to receive products made with care, attention, and skill. When you partner with a manufacturer who shares this philosophy, you’re making a statement about what your brand values.

Customers notice this, and many are willing to pay a modest premium for it. According to research from Cone Communications, 87% of consumers will purchase a product based on a company’s advocacy of social or environmental issues. Treating craftsmanship as a baseline rather than a luxury feature, ensuring that affordable products receive genuine care—these are values that resonate with conscious consumers who increasingly dominate the jade and crystal market.

Taking the First Step Toward Consistent Quality

What a Partnership with Jade Mago Actually Looks Like

If you’re reading this and recognizing the quality inconsistency problems in your current supply chain, you might be wondering what it would actually look like to transition to a manufacturer with uniform processing standards. Let me walk you through what that journey typically involves.

It starts with a transparent quality audit where we compare how most factories would process your items versus our approach. We look at your current product specifications and show you specifically where corners typically get cut on affordable items—and how we maintain standards in those exact areas. This isn’t about criticizing your current manufacturer; it’s about helping you understand what consistent standards actually mean in practice.

From there, we move into sample production using your exact production specifications. This is crucial because it lets you evaluate not just the final product, but the entire process. You’ll see the documentation from each quality checkpoint. You’ll understand the timeline and how it remains consistent regardless of material cost. You’ll be able to ask questions about any aspect of the workflow and get detailed answers from the craftspeople actually doing the work.

The Investment Required (And Why It’s Worth It)

I won’t pretend that maintaining uniform high standards across all price points costs the same as tiered production systems. It doesn’t. When you’re applying premium processing techniques to affordable materials, you’re investing more per piece than manufacturers who cut corners on cheaper items. This typically translates to a 10-15% higher manufacturing cost compared to facilities using tiered standards.

But consider what you’re getting for that investment. You’re getting 99.3% acceptance rates, which means virtually no money wasted on remakes or returns. You’re getting under 0.5% return rates from your end customers, which means minimal reverse logistics costs and preserved customer relationships. You’re getting the ability to confidently expand your product line knowing that quality will remain consistent. You’re getting authentic marketing stories about your commitment to craftsmanship.

Perhaps most importantly, you’re getting peace of mind. No more anxiety about “will this batch meet standards?” No more surprises when production quality doesn’t match sample quality. No more managing the reputational damage when affordable items feel cheap compared to premium offerings. That peace of mind has real business value that’s hard to quantify but impossible to ignore once you experience it.

Conclusion

The question we started with—”Is there any difference in jade processing between a $20,000 piece of jade and a $200 crystal?”—has a more complex answer than it might seem. Yes, there are differences in material rarity, in cultural significance, in the complexity of certain carvings that command premium prices. But should there be differences in the fundamental craftsmanship, in the care and attention given to processing, in the quality standards applied?

At Jade Mago, we believe absolutely not. We believe that the grandmother opening her granddaughter’s graduation gift—a $200 jade pendant—should feel the same quality, care, and respect that went into someone’s $20,000 investment piece. We believe that your brand’s integrity shouldn’t depend on which price point a customer chooses. We believe that craftsmanship isn’t a luxury feature you add to expensive items; it’s a baseline standard you apply to everything.

This philosophy has guided us for more than six decades. It’s led us to turn down profitable projects that asked us to compromise. It’s required investments in training, equipment, and processes that many manufacturers would consider excessive for “just affordable items.” But it’s also given us the highest quality acceptance rates in the industry, the most loyal partner relationships, and the deep satisfaction of knowing that every piece bearing our craftsmanship upholds the values we hold dear.

If you’re tired of managing the chaos of inconsistent quality, if you’re ready to build a brand where your quality promise is verified reality rather than marketing aspiration, if you believe your customers deserve respect regardless of what they can afford to spend—then perhaps it’s time we talked. Request a transparent quality audit today and see the difference non-negotiable standards make. Because at Jade Mago, we believe every piece tells a story. Shouldn’t that story always be one of craftsmanship, care, and respect?

Frequently Asked Questions

Does the material price affect processing standards at Jade Mago?

No. We believe production standards should never be negotiable, regardless of the material’s price tag. Whether it is a $20,000 piece of jade or a $200 crystal, they follow the exact same processing workflow.

How do you ensure quality consistency across different price points?

Every piece must pass through the same seven critical stages: material assessment, CAD precision modeling, master craftsperson processing, hand-finishing, multi-stage polishing, seven quality checkpoints, and standardized packaging.

Are lower-priced products also processed by experienced craftsmen?

Yes. In our facility, material cost does not determine craftsperson assignment

. The person carving a $200 piece has the same skill level and at least ten years of specialized experience as the person working on a $20,000 piece.

-900x375.webp)