Introduction

In 2023, a mid-sized jewelry retailer in California faced a $47,000 settlement after customers discovered their “natural blue chalcedony” bracelets were actually dyed agate. The Federal Trade Commission (FTC) classified this as commercial fraud under 16 CFR Part 23, and the brand’s Amazon account was permanently suspended within 72 hours.

This isn’t an isolated incident. For B2B buyers—whether you’re a cross-border e-commerce operator, jewelry designer, or procurement manager—mislabeling agate and chalcedony represents one of the most financially dangerous mistakes in the gemstone supply chain. The stakes go far beyond embarrassment: incorrect product labeling triggers legal liabilities, mass returns, platform bans, and irreversible brand damage.

What makes this issue particularly treacherous is that both materials are forms of microcrystalline quartz, visually similar to untrained eyes, yet governed by strict regulatory distinctions in international trade standards. According to gemological laboratories, the difference lies in a single structural feature that determines not only the correct scientific name but also your legal compliance status across multiple markets.

At JADE MAGO, with 65 years of natural gemstone processing expertise, we’ve witnessed countless supply chain disasters stemming from this fundamental identification error. This comprehensive guide will equip you with laboratory-grade authentication methods, reveal hidden supplier fraud tactics, and provide actionable protocols to protect your business from compliance violations that could cost six figures overnight.

Table of Contents

The Scientific Foundation: What Gemological Labs Actually Examine

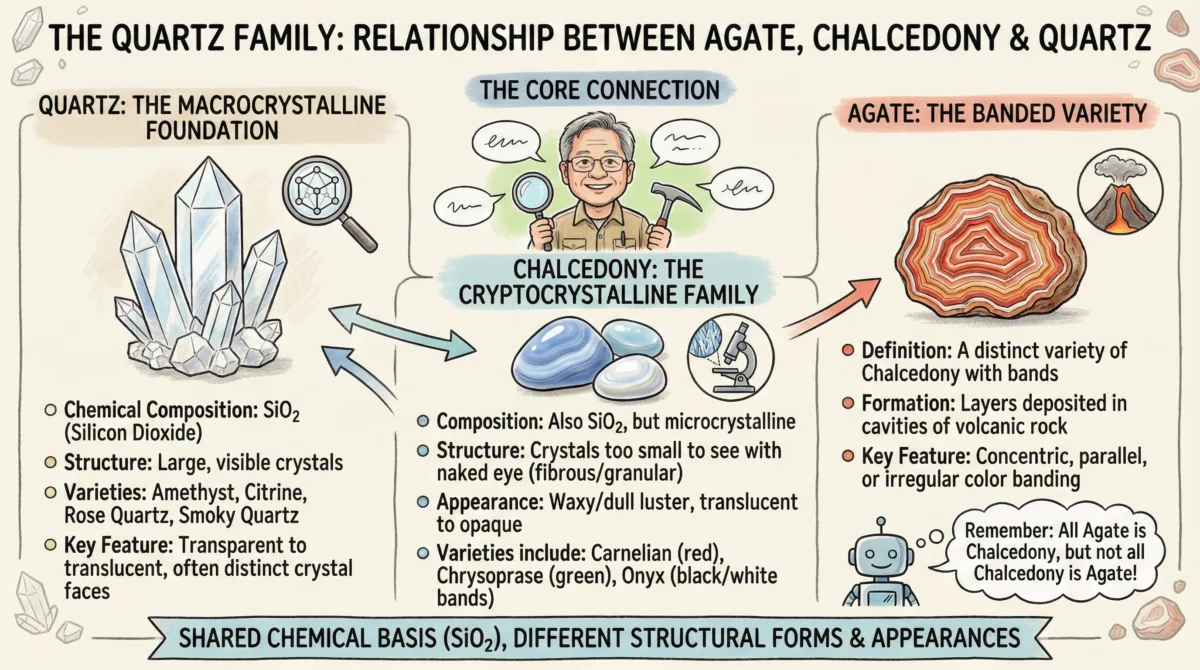

Understanding the technical distinction between agate and chalcedony isn’t academic hairsplitting—it’s the foundation of legally defensible product labeling. Both materials belong to the chalcedony family in mineralogical classification, which often confuses even experienced buyers. However, gemological institutes like GIA (Gemological Institute of America) and IGS (International Gem Society) apply a specific criterion that determines the correct nomenclature: the presence or absence of visible banding structure.

At the molecular level, both agate and chalcedony are composed of silicon dioxide (SiO2) in microcrystalline or cryptocrystalline form, meaning their crystal structures are too small to be seen without high-powered microscopy [Reference Link to GIA source]. Their physical properties are nearly identical: hardness of 6.5-7 on the Mohs scale, specific gravity around 2.60-2.64, and similar refractive indices. This chemical sameness is precisely why visual inspection alone fails so catastrophically in procurement scenarios. The decisive factor lies not in composition but in structural arrangement during formation.

Agate forms in volcanic or metamorphic rocks through a process of rhythmic crystallization, where silica-rich fluids deposit successive layers in cavities. These layers contain varying concentrations of trace minerals—iron, manganese, titanium—which create visible color bands or transparency gradients.

According to IGS standards, for a specimen to be correctly labeled as “agate,” these bands must be discernible to the naked eye or under 10x magnification, the industry standard for gemstone grading . The banding can appear as parallel lines, concentric circles, or irregular patterns, but visibility is the non-negotiable requirement.

Chalcedony, by contrast, crystallizes uniformly without rhythmic deposition. The result is a homogeneous mass with consistent color and transparency throughout. Premium varieties like blue chalcedony, chrysoprase (green chalcedony), or carnelian (red-orange chalcedony) command significantly higher per-carat prices precisely because of this uniformity—making them prime targets for substitution fraud in supply chains.

The Treatment Dilemma: When “Natural” Becomes Legally Problematic

The second critical complexity in agate vs chalcedony identification involves post-mining treatments, an area where JADE MAGO’s decades of manufacturing experience reveals the deepest pitfalls. Industry data suggests that over 80% of commercially available agate undergoes some form of enhancement—primarily heat treatment or chemical dyeing—to intensify colors that would otherwise appear dull or unattractive to consumers. The legal landmine here is not the treatment itself, but the disclosure requirements that vary dramatically across jurisdictions.

Heat treatment, when properly executed through controlled industrial furnaces, causes a permanent molecular rearrangement that stabilizes color changes. This process is classified as “enhancement” rather than “treatment” under most international standards, including those recognized by CIBJO (The World Jewellery Confederation). Crucially, many markets—including the United States under FTC guidelines and the European Union under consumer protection directives—do not require mandatory disclosure of heat treatment for agate, provided the structural integrity remains unchanged [Reference Link to FTC 16 CFR Part 23]. At JADE MAGO, our temperature-controlled electric furnaces operate within precise parameters (typically 400-600°C for specific durations) to achieve vibrant reds, oranges, and browns through iron oxide oxidation, a method that satisfies the “permanent and stable” criterion in gemological standards.

Chemical dyeing presents an entirely different legal scenario. When agate is immersed in chemical solutions—commonly using aniline dyes, ferric nitrate, or chromium compounds—to impart blues, greens, or purples not naturally achievable through heat, this must be disclosed as “dyed agate” or “color-treated agate” on all commercial documentation and consumer-facing labels. Failure to disclose dyeing constitutes material misrepresentation under FTC Section 5, potentially triggering federal penalties starting at $43,792 per violation as of 2024 [Reference Link to FTC penalty guidelines]. The nightmare scenario we’ve seen repeatedly: suppliers delivering dyed material labeled as “natural,” which buyers then unknowingly market as untreated, creating a chain of liability that ends with the brand owner facing class-action lawsuits.

Three Critical Supply Chain Vulnerabilities

The gap between laboratory standards and real-world procurement creates specific exploitation points that unscrupulous suppliers leverage systematically. Understanding these vulnerabilities isn’t pessimistic—it’s essential risk management for any serious B2B operation in the gemstone sector.

Price Arbitrage Fraud: The Economics of Substitution

The first vulnerability stems from the significant price differential between quality chalcedony and common agate. Blue chalcedony from Turkey or Namibia can trade at $15-50 per carat for jewelry-grade material, while mass-market agate from Brazil or India may cost $0.50-3 per carat. This 10-30x price gap creates enormous economic incentive for substitution, particularly in bulk orders where visual inspection of every piece is impractical. A common fraud pattern involves suppliers accepting orders for “500kg blue chalcedony cabochons” but delivering a mix where 30-60% consists of heat-treated or dyed agate with artificially uniform coloring.

The deception succeeds because casual inspection doesn’t reveal banding in polished, translucent pieces, especially when viewed under showroom lighting rather than transmitted light. We’ve documented cases where entire container shipments passed initial QC checks, only for the fraud to be discovered months later when end customers complained about color bleeding or inconsistency in supposedly “natural chalcedony” products. The financial damage extends beyond the material cost difference—when a jewelry brand built its marketing campaign around “rare blue chalcedony,” discovering the reality forces a choice between silence (legal risk) or disclosure (brand credibility collapse).

JADE MAGO’s counter-strategy begins at raw material procurement. Our 10-year relationships with mine operators in major source regions—including Xuanhua agate mines in Hebei, China, and chalcedony deposits in Madagascar—enable direct purchase of rough material, bypassing intermediaries who might mix sources. Before any cutting or polishing, our gemologists conduct preliminary sorting using transmitted light examination, where banding in agate becomes immediately apparent even in rough form. This “pre-processing authentication” stage prevents contaminated material from entering production lines, ensuring that orders specified as chalcedony contain zero agate substitution. For clients requiring absolute verification, we provide third-party laboratory certification from SGS or similar institutions, with per-piece testing available for high-value orders.

Batch Inconsistency: The Hidden Brand Killer

The second vulnerability is more insidious because it doesn’t involve intentional fraud but rather inadequate quality systems that allow agate and chalcedony to mix within the same order. This typically occurs with smaller manufacturers who lack segregated processing lines or rigorous batch tracking. The result: a customer ordering 10,000 “green chalcedony” beads receives a shipment where 70% meet specifications, 20% are actually green agate with faint banding, and 10% are dyed quartzite—a completely different material.

For consumer-facing brands, this creates catastrophic outcomes. Imagine an e-commerce seller photographing products using the highest-quality pieces from a batch, listing them as “premium chrysoprase chalcedony,” then randomly fulfilling orders from the same batch. Early customers receive the photographed quality; later customers get inferior mixed material. The inevitable result: a surge of negative reviews claiming “not as pictured” or “cheap quality,” combined with return rates that can hit 30-40% on that SKU. Amazon’s algorithm penalizes high return rates by suppressing product rankings, creating a death spiral where marketing spend yields diminishing returns on increasingly skeptical traffic.

At JADE MAGO, we implement physical segregation protocols that treat agate and chalcedony as separate product lines from rough material intake through final packaging. Our factory operates dedicated processing zones: Workshop A handles exclusively agate material (with subdivisions for natural vs. heat-treated), while Workshop B processes chalcedony varieties. This segregation extends to cutting tools—diamond saw blades and grinding wheels used for chalcedony never touch agate material, preventing cross-contamination of micro-particles that could affect subsequent batches. During rough sorting, any questionable pieces that show even marginal banding under 10x loupe examination are automatically classified as agate, erring on the side of caution.

Our three-stage quality control system provides additional safeguards. Stage One occurs at rough material intake, where senior gemologists (averaging 20+ years experience) conduct transmitted light examination of every incoming batch. Stage Two happens after preliminary shaping but before final polishing, when surface features become visible but can still be corrected. Stage Three is final inspection of finished goods, where every piece in orders above 500 units undergoes individual examination, and random sampling (minimum 10%) applies to smaller orders. This systematic approach results in batch consistency rates exceeding 98%, meaning fewer than 2 in 100 pieces deviate from specified material characteristics—a critical metric for brands that depend on repeatable product quality.

Treatment Disclosure Gaps: The Compliance Minefield

The third vulnerability involves the absence of clear treatment documentation in supply chains, particularly for enhanced agate. Many manufacturers—especially smaller operations—perform heat treatment or dyeing without maintaining records of which batches underwent which processes. This “documentation void” becomes a legal liability time bomb when products reach regulated markets.

Consider a typical scenario: a European jewelry brand sources “natural red agate” beads from a Chinese supplier at competitive pricing. The supplier genuinely believes the material is natural because their own source (a secondary trader) told them so. In reality, the rough agate was heat-treated two supply chain steps earlier to convert pale brown material into vivid red through iron oxide oxidation. The European brand imports and sells the beads, marketing them as “natural carnelian agate” to justify premium pricing. Eighteen months later, a competitor files a complaint with consumer protection authorities, triggering laboratory analysis that reveals heat treatment. Under EU consumer protection laws, the brand faces penalties for misleading product descriptions, plus mandatory recalls and customer refunds—easily exceeding €100,000 in costs for a small-to-medium enterprise.

The fundamental problem is that heat treatment, while legally acceptable without disclosure in many jurisdictions, still represents a material fact that sophisticated buyers want to know—especially if they’re operating in markets with stricter standards or serving customers who specifically seek untreated materials. JADE MAGO addresses this through our dual-track production system. Track One handles exclusively natural, untreated material with full chain-of-custody documentation from mine to finished product. Clients selecting this track receive materials with absolutely zero enhancement, certified by laboratory reports confirming no treatment indicators (checked via UV fluorescence, magnification, and spectroscopic analysis when necessary).

Track Two offers “compliant enhancement” services for clients who need vibrant colors but must maintain legal compliance. Our industrial electric furnaces operate with programmable temperature controllers that log every heating cycle, creating a permanent record of processing parameters. Each batch processed through Track Two receives a Treatment Disclosure Certificate specifying the enhancement method (heat treatment), temperature range, duration, and stability assessment. This documentation satisfies disclosure requirements in jurisdictions that mandate treatment transparency, while the physical permanence of heat-induced color changes meets the “stable and permanent” standard that distinguishes acceptable enhancement from temporary or unstable treatments.

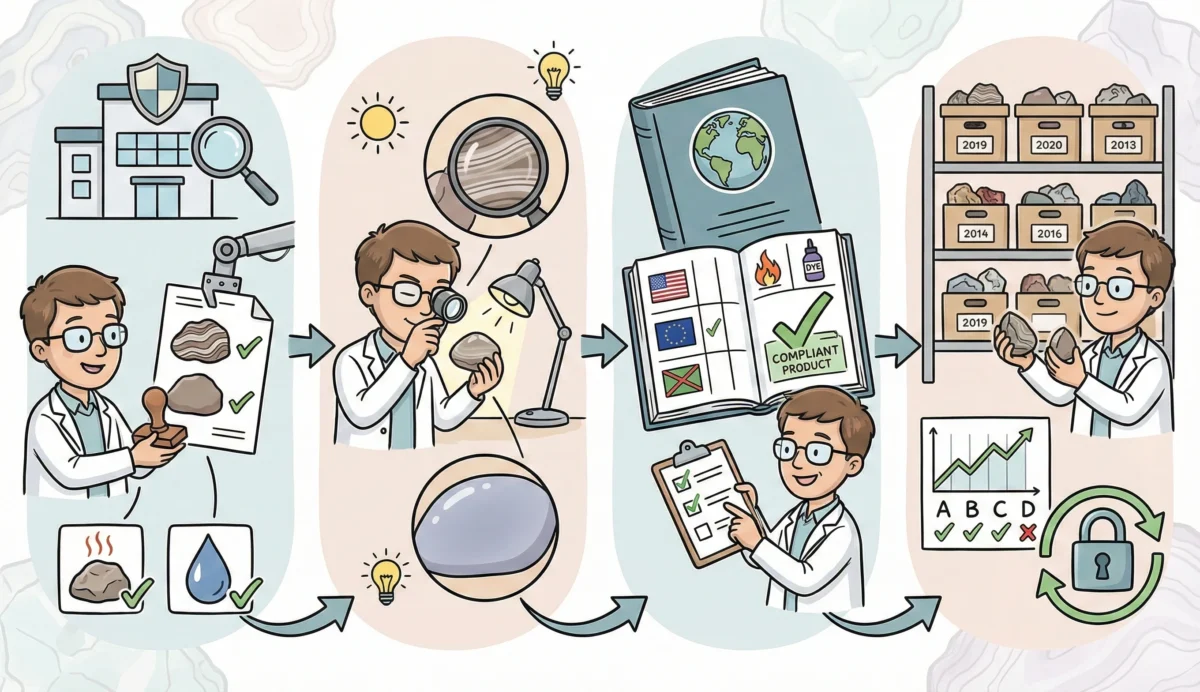

The Four-Step Authentication Protocol for B2B Procurement

Establishing reliable agate vs chalcedony identification within your supply chain requires a systematic approach that combines supplier requirements, hands-on verification, regulatory compliance checks, and ongoing quality monitoring. This protocol is designed for implementation by procurement teams without requiring gemological certification, though we strongly recommend having at least one trained professional on staff for high-volume operations.

Step One: Demand Pre-Shipment Laboratory Documentation

The foundation of any secure procurement process is third-party verification before materials leave the supplier’s facility. Reputable gemstone manufacturers should be willing—and able—to provide laboratory analysis reports from accredited institutions such as GIA, SSEF (Swiss Gemmological Institute), or national gemological institutes like NGTC (National Gemstone Testing Center) in China. These reports must contain specific information beyond generic mineral identification.

A compliant laboratory report for agate must note the presence of banding structure, typically described as “characteristic banding” or “layered structure with color variation.” For chalcedony, the report should state “uniform structure” or “no banding observed.” Critically, treatment disclosure must be explicit: reports should state “no indications of treatment” for natural material, or specify “heat treatment evident” or “artificial coloration detected” when enhancements are present [Reference Link to GIA report standards]. Be extremely wary of vague language like “appears natural”—this phrasing provides the laboratory with plausible deniability while giving suppliers false documentation to show buyers.

At JADE MAGO, we provide these reports as standard documentation for orders exceeding 5,000 units or $10,000 value, whichever threshold is met first. For smaller orders, we offer laboratory testing as an optional service at cost (typically $150-300 per batch depending on complexity). We also maintain an internal database of laboratory reports spanning our 65-year operational history, allowing clients to cross-reference current shipments against historical data for the same material sources—an additional verification layer that catches source-switching fraud.

Step Two: Implement Hands-On Visual Verification

While laboratory reports provide scientific certainty, they’re impractical for every-piece verification in bulk orders. This is where systematic visual examination becomes essential, using tools and techniques adapted from professional gemology but simplified for procurement team use. The primary tool is a 10x jeweler’s loupe or a USB digital microscope, which provides sufficient magnification to detect banding in most agate specimens.

The examination procedure requires proper lighting—ideally a daylight-balanced LED light source or natural sunlight, avoiding the warm-toned lighting common in showrooms that can mask subtle color variations. For translucent pieces like polished cabochons or beads, transmitted light examination (holding the piece between eye and light source) reveals internal structures invisible in reflected light. Agate’s characteristic banding appears as parallel lines, concentric circles, or irregular patterns where different layers show varying transparency or color. Even subtle banding that wouldn’t be visible to casual observers disqualifies a piece from being labeled as chalcedony—the standard is “discernible under 10x magnification,” not “obvious to everyone.”

For opaque or semi-opaque material, surface examination under magnification may reveal banding as subtle ridges or color transitions, particularly on broken or unpolished surfaces. This is why JADE MAGO recommends that clients request a small quantity of rough or semi-finished material alongside polished pieces in initial orders—rough surfaces reveal banding more readily than mirror-polished ones. We train our clients’ procurement teams during factory visits, providing hands-on practice with known agate and chalcedony samples under various lighting conditions. This practical education typically takes 3-4 hours but dramatically reduces authentication errors in ongoing operations.

Document your findings systematically. For each batch inspection, record date, batch identifier, number of pieces examined, magnification used, lighting conditions, and findings (banding present/absent, treatment indications, quality consistency). This documentation serves dual purposes: it creates an audit trail demonstrating due diligence if compliance issues arise, and it builds institutional knowledge that helps identify supplier quality trends over time. After six months of consistent documentation, patterns emerge—you’ll know which suppliers maintain consistent quality versus those showing increasing deviation rates.

Step Three: Verify Treatment Disclosure Regulatory Compliance

Even when you’ve correctly identified material as agate or chalcedony, the treatment disclosure question remains. Different target markets have different requirements, and failing to understand these variations creates compliance gaps. The FTC’s Guides for the Jewelry, Precious Metals, and Pewter Industries (16 CFR Part 23) serve as the reference standard for US-bound products, while EU markets follow Consumer Rights Directive 2011/83/EU, and other regions have their own frameworks .

Under FTC guidelines, the key principle is that any treatment “that is not permanent or creates special care requirements” must be disclosed. Heat treatment of agate, because it produces permanent color changes through irreversible chemical reactions, generally does not require disclosure in the US market. However, this exemption applies only when the treatment is genuinely stable—temporary or unstable treatments must be disclosed. Dyeing always requires disclosure, typically through terminology like “dyed,” “color-enhanced,” or “artificially colored.” The exact phrasing matters less than ensuring the disclosure is clear and conspicuous, meaning a reasonable consumer would notice and understand it.

Create a compliance matrix mapping your target markets against their disclosure requirements. This matrix should specify mandatory disclosure language for each treatment type in each market. For example, your matrix might show: “US Market – Heat-treated agate: no disclosure required / Dyed agate: must state ‘dyed’ or ‘color-treated’ adjacent to product name. EU Market – Heat-treated agate: disclose as ‘heated’ in product description / Dyed agate: must state ‘artificially colored’ in both product title and description.” Share this matrix with your suppliers, making it clear that their invoices and packing lists must flag treatment types so your team can apply correct labeling.

JADE MAGO includes treatment disclosure information on three levels of documentation: the batch quality certificate (internal document), the commercial invoice (for customs and client records), and product-specific labels or hangtags (when clients request them). This redundancy ensures that treatment information cannot be “lost” during handoffs within your organization—whether warehouse staff, marketing teams, or customer service representatives need the information, it’s available in multiple accessible locations. We also provide digital QR codes that link to detailed material specifications including treatment history, particularly valuable for brands targeting transparency-conscious consumer segments.

Step Four: Establish Batch Consistency Monitoring Systems

The final protocol step addresses the ongoing challenge of maintaining quality consistency across multiple orders over time. Even when a supplier delivers perfect material on the first three orders, there’s no guarantee that order four won’t contain substitutions or quality drift. Systematic monitoring catches these issues early, before they contaminate your inventory and reach end customers.

Implement a reference sample system where you retain 10-20 pieces from each approved batch, storing them in labeled containers with batch numbers and receipt dates. When new orders arrive from the same supplier for the same material specification, conduct side-by-side comparisons between the reference samples and new shipment. Look for color shifts, pattern differences, size variations, or finish quality changes. Even small deviations—slightly duller color, marginally rougher polish, or occasional banding in supposedly chalcedony material—signal process control problems at the supplier’s facility that will likely worsen over time if not addressed.

Track deviation rates across suppliers using a simple scoring system. For each batch received, assign quality scores: A (meets specifications perfectly, 0-2% deviation), B (meets specifications with minor inconsistencies, 3-5% deviation), C (acceptable but showing quality drift, 6-10% deviation), or D (unacceptable, requires return or price adjustment, over 10% deviation). Graph these scores over time to visualize supplier performance trends. A supplier whose scores trend from consistent As to occasional Bs might be experiencing growth-related quality control challenges. A supplier showing sudden drops from A to C or D likely changed their sourcing or processing without disclosure—a red flag requiring immediate investigation.

JADE MAGO maintains our own internal reference library containing over 3,000 categorized samples representing different agate and chalcedony varieties from major global sources, accumulated over our 15 year operational history. When clients question whether a specific piece meets their specifications, we can compare it against our reference library to provide historical context: “This is typical of Brazilian agate from Soledade deposits” or “This doesn’t match any known natural blue chalcedony characteristics, suggesting treatment.” This institutional knowledge, built through decades of hands-on experience with hundreds of millions of processed gemstones, represents a competitive advantage that newer or smaller manufacturers simply cannot replicate.

Why JADE MAGO’s Manufacturing Legacy Translates to Compliance Assurance

Understanding the theoretical basis of agate vs chalcedony identification is valuable, but translating that knowledge into reliable supply chain operations requires manufacturing infrastructure and expertise that develops only through sustained operational excellence. JADE MAGO, having passed through three generations of heritage and drawing upon 65 years of expertise in natural gemstone processing, has developed three core strengths that directly impact clients’ compliance outcomes.

First, our source network stability ensures material authenticity at origin. Since our founding in 2009, we’ve maintained direct relationships with mine operators and extraction cooperatives in primary source regions—not just in China (Xuanhua, Fuxin, and Alxa agate sources; Inner Mongolia and Qinghai chalcedony sources) but also internationally including Madagascar, Uruguay, and Namibia. These relationships mean we’re purchasing rough material directly from extraction points, not through trading chains where material origin becomes obscured and mixing occurs. When we specify “Madagascar blue chalcedony” on a client’s order, we have photographic documentation of the specific mine face where that rough was extracted, and extraction date records. This traceability is impossible for suppliers dependent on secondary markets.

Secondly, our technical team comprises multiple professionals with over 20 years of hands-on expertise in relevant specialties. This level of proficiency cannot be achieved through certificates alone—in our industry, a seasoned gemologist must master evolving identification techniques and testing methods through continuous practical experience and firsthand observation. These skills cannot be taught in academic settings, though we also employ designers from institutions like the Central Academy of Fine Arts in China. Such expertise must permeate every quality control stage, from rough stone evaluation to finished product inspection. When encountering ambiguous cases—such as minute banding samples at the threshold of visibility or anomalous color characteristics potentially indicating undisclosed treatments—our battle-tested team delivers precise judgments through professional training, rather than relying on guesswork or blindly accepting supplier claims.

Third, our dual-production-track system offers clients genuine choice rather than forcing them into all-or-nothing decisions. Some clients need absolutely untreated material because they’re targeting premium market segments or operating in jurisdictions with strict disclosure requirements. Other clients need cost-effective material with vibrant colors that untreated agate rarely provides, but they can’t risk non-compliant dyeing. Our Natural Track and Enhanced Track accommodate both needs within the same facility, with rigorous segregation preventing cross-contamination. Clients can even split orders—requesting 60% from Natural Track for flagship product lines, and 40% from Enhanced Track for value-tier products—with full confidence that they’ll receive exactly what they ordered.

This operational flexibility is particularly valuable for brands navigating the emerging regulatory landscape around sustainability claims and supply chain transparency. The EU’s upcoming Digital Product Passport requirements, expected to affect jewelry and gemstones by 2027-2028, will mandate detailed disclosure of material origin, processing methods, and treatment history . Brands that build compliance infrastructure now—starting with suppliers like JADE MAGO who already maintain comprehensive documentation—will face minimal disruption when these regulations take effect. Those relying on suppliers without robust traceability systems will face costly emergency transitions or potential market access restrictions.

Conclusion

The agate vs chalcedony identification challenge represents more than a technical quality control issue—it’s a litmus test for supply chain sophistication that separates professional B2B operations from amateur-hour operations destined for compliance disasters. The gemstone industry’s structure, with its long supply chains, multiple intermediaries, and information asymmetries between miners, processors, and end-buyers, creates systematic opportunities for errors and fraud that disproportionately harm brands rather than upstream suppliers.

In 2025’s regulatory environment, platform monitoring has intensified dramatically. Amazon’s Brand Registry now employs AI-powered listing analysis that flags potentially misleading gemstone terminology, triggering human review that can result in ASIN suspension within 24-48 hours. Etsy’s Handmade and Supplies categories now require sellers to provide material certification documentation upon request, with non-compliance leading to shop suspension. Even smaller platforms like eBay have updated their gems and jewelry policies to require specific disclosure language for treated materials. These enforcement actions don’t just affect immediate sales—they create negative signals in Google search results, erode customer trust that takes years to rebuild, and potentially trigger regulatory investigations if pattern complaints emerge.

Forward-thinking brands recognize that superior compliance infrastructure creates competitive advantages that translate directly to financial performance. When competitors face platform suspensions, compliant brands capture their orphaned traffic and disillusioned customers. When regulatory agencies announce enforcement sweeps, compliant brands continue operations uninterrupted while competitors scramble with emergency supplier changes and costly inventory write-offs. When sophisticated buyers (retail chains, museum shops, high-end boutiques) conduct supplier audits, compliant brands pass where others fail, accessing premium distribution channels that reject questionable suppliers.

The investment required to build this compliance infrastructure is modest compared to the downside protection it provides. Implementing the four-step authentication protocol outlined in this guide requires initial setup time and ongoing operational overhead (approximately 3-5% additional processing time per shipment). These costs are negligible when weighed against a single major compliance incident’s potential six-figure liability.

We invite B2B buyers serious about building sustainable, compliant gemstone supply chains to engage with JADE MAGO’s team beyond transactional supplier relationships.

FAQ

Why does my Agate jewelry certificate identify the material as “Chalcedony”? Is this a mistake?

No, it is not a mistake. From a mineralogical perspective, Agate is a variety of Chalcedony characterized by its banded structure. Many national standards (such as China’s GB/T 16552) categorize Agate under the broader umbrella of “Chalcedony.” Therefore, labeling it as Chalcedony is scientifically and legally accurate.

Can I label all Chalcedony products as “Agate” to increase their market value?

No. The key distinction in labeling compliance lies in the visible banding. To be legally labeled as “Agate,” the stone must exhibit distinct concentric or parallel layers. If the material is translucent and uniform without any banding, it must be labeled as “Chalcedony.” Mislabeling can lead to consumer fraud claims.

What are the most critical factors for compliance in B2B gemstone trade?

Compliance is primarily based on structural characteristics and laboratory verification. For international trade, labels must strictly match the official test report. If a certificate lists “Chalcedony (Agate),” both terms can be used. If it only lists “Chalcedony,” sellers should not unilaterally change the label to “Agate” for marketing purposes.

Are there specific labeling requirements for dyed or treated Agate?

Yes. While standard heat treatment is often accepted without disclosure in some regions, dyeing (color enhancement) must be clearly disclosed. Labels and certificates should state “Dyed Agate” or “Agate (Treated).” Failing to disclose such treatments is a major compliance violation in most jurisdictions.

-900x375.webp)