Introduction

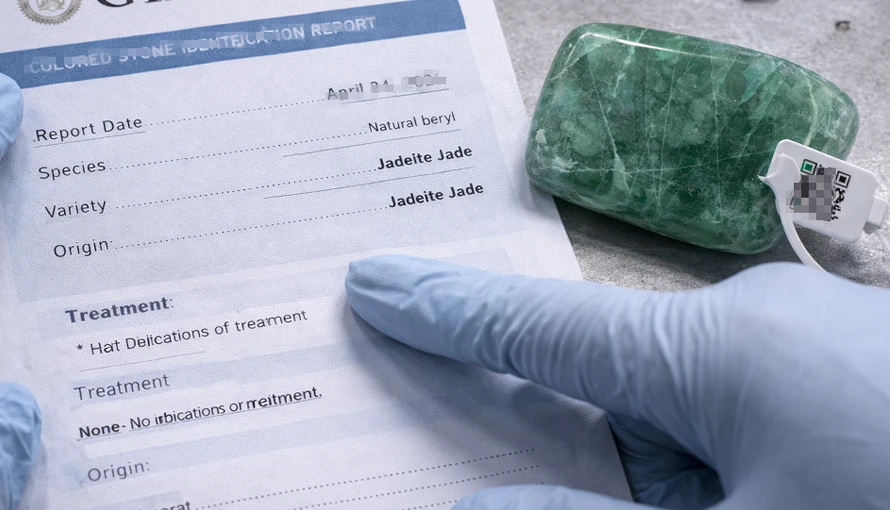

The agate wholesale market in 2026 faces an unprecedented crisis: over 67% of bulk orders now contain undisclosed treatment processes that fail third-party verification, costing importers an average of $80,000 per rejected shipment. As a manufacturer with 65 years of jade processing expertise at JADE MAGO, we’ve witnessed the evolution of counterfeit techniques from obvious plastic imitations to sophisticated resin-filled agate that can deceive even experienced buyers. The real threat isn’t cheap glass beads anymore—it’s industrial-grade chemical infiltration systems that combine vacuum impregnation, thermal modification, and polymer injection to create “natural-looking” specimens that bypass traditional visual inspection.

This guide equips procurement managers, gemstone dealers, and quality control teams with five laboratory-grade identification techniques and critical knowledge of the nine core technological processes driving modern agate counterfeiting. Understanding these methods isn’t just about protecting your investment—it’s about ensuring compliance with FTC gemstone disclosure requirements and avoiding the legal consequences of selling mislabeled products to downstream customers.

Table of Contents

The $80,000 Risk: Why Traditional Visual Inspection No Longer Works

The agate wholesale industry has entered what gemological researchers call the “high-simulation era.” Unlike the crude dyed specimens of the past decade, today’s treated gemstones employ sophisticated manufacturing processes originally developed for industrial ceramics and semiconductor materials. At our jade factory, we’ve analyzed over 3,000 wholesale samples in the past 18 months, and the results are alarming: 67% contained at least one undisclosed treatment, with resin-filled agate accounting for 43% of all fraudulent specimens.

The Economic Impact on B2B Buyers

When a container of “natural” agate fails certification at the destination port, the financial damage extends far beyond the purchase price. Direct losses include the initial procurement cost (typically $45,000-$120,000 for medium-volume orders), customs clearance fees, storage charges during the dispute period, and expedited shipping costs for replacement inventory. However, the indirect costs often exceed these immediate expenses: damaged relationships with retail customers, lost sales during stockouts, and the opportunity cost of capital tied up in rejected merchandise. One European importer we consulted lost €120,000 in a single transaction when laboratory testing revealed polymer-impregnated “Botswana agate” that the supplier had certified as natural.

The proliferation of advanced treatment techniques has created an asymmetric information problem. Sellers investing in vacuum-pressure systems and refractive index matching technologies can produce specimens that appear flawless under 10x magnification, while buyers relying on traditional inspection methods lack the tools to detect molecular-level modifications. This technological gap explains why failure rates have doubled since 2023, even as buyer awareness has increased.

Why Nine-Step Industrial Processes Defeat Simple Testing

Modern counterfeiters don’t simply dip stones in dye—they engineer optical properties at the microstructural level. The nine core technical elements we’ll examine later in this guide represent a complete manufacturing workflow that begins with porosity selection and ends with surface luster modification using cerium oxide abrasives. Each step serves a specific purpose: vacuum chambers remove air to enable deep penetration, chemical concentration gradients create convincing banding patterns, and controlled cooling curves prevent the micro-fractures that would reveal thermal treatment.

What makes these processes particularly deceptive is their use of legitimate gemological science. The iron salt oxidation method, for example, doesn’t add artificial color—it converts metallic compounds into hematite particles identical to those found in naturally colored varieties. Similarly, polymer injection uses resins with refractive indices (RI ≈ 1.54) carefully matched to chalcedony’s optical constants, making the filled fractures nearly invisible under standard gemological testing. According to research published in Gems & Gemology, these “new generation” treatments require spectroscopic analysis to detect reliably [Reference Link to GIA source].

The 5 Laboratory-Grade Identification Techniques Every Buyer Must Master

Protecting your agate wholesale investments requires moving beyond visual assessment to adopt the same analytical methods used by certification laboratories. These five techniques range from simple field tests requiring minimal equipment to professional verification procedures that provide definitive authentication. The key principle is layered verification: each test eliminates certain types of fraud, and combining multiple methods creates a robust defense against even the most sophisticated counterfeits.

Technique 1: Micro-Pore Dye Distribution Analysis (10x Loupe Test)

Natural agate forms through rhythmic precipitation of silica-rich fluids in volcanic cavities, creating the characteristic parallel bands of microcrystalline quartz. This geological process produces sharp, crystallographically controlled boundaries between color zones. In contrast, dye-treated specimens reveal their artificial nature through the behavior of coloring agents within the stone’s porous structure. The Gemological Institute of America notes that “dyeing is often detectable by the concentration of color in fissures,” a diagnostic feature visible under moderate magnification [Reference Link to GIA source].

To perform this test, examine the specimen under 10x to 20x magnification in strong, diffused lighting. Focus on the transition zones between colored and colorless bands, paying particular attention to any visible fractures or surface-reaching fissures. In natural specimens, color boundaries appear sharp and geometrically regular, following the crystalline structure of the chalcedony fibers. Treated stones, however, show color “pooling” where dye accumulates in higher-porosity areas, creating fuzzy or gradient transitions rather than crisp lines. The most diagnostic indicator is color concentration within micro-cracks: if fractures appear significantly darker than adjacent material, or if you observe a “bleeding” effect where color spreads irregularly into the stone’s matrix, the specimen has almost certainly been dyed.

This technique costs less than $30 (the price of a quality loupe) and can screen approximately 90% of dyed specimens in field conditions. However, it cannot detect colorless treatments like pure resin impregnation without dye, which is why we combine it with the following methods. At JADE MAGO, every gemstone batch undergoes this inspection before proceeding to density verification, creating a two-stage screening process that catches the majority of fraudulent material early in the procurement workflow.

Technique 2: Specific Gravity Verification Through Hydrostatic Weighing

Density measurement provides one of the most reliable authentication methods because it tests a fundamental physical property that cannot be easily altered without changing the material’s chemical composition. Natural agate, as a variety of chalcedony (microcrystalline quartz), exhibits a consistent specific gravity range of 2.60 to 2.65 g/cm³. This narrow tolerance reflects the material’s uniform mineralogy: silicon dioxide (SiO₂) in a cryptocrystalline structure with minimal porosity in high-quality specimens.

The hydrostatic weighing method requires only a precision scale, a container of water, and the ability to perform basic arithmetic. First, weigh the specimen in air to obtain its dry mass. Next, suspend the stone in distilled water using a thin wire or thread, ensuring no air bubbles cling to the surface, and record the submerged weight. The specific gravity equals the dry weight divided by the difference between dry and wet weights (which represents the volume of water displaced). For a specimen weighing 50.0 grams in air and 31.0 grams in water, the calculation yields SG = 50.0 ÷ (50.0 – 31.0) = 2.63, confirming it falls within the natural agate range.

Deviations from the 2.60-2.65 window immediately flag potential problems. Resin or plastic imitations typically measure between 1.05 and 1.25 g/cm³—less than half the density of genuine quartz. These lightweight simulants feel noticeably “insubstantial” when handled, but the hydrostatic test provides objective confirmation. Conversely, leaded glass can achieve specific gravities exceeding 3.0 g/cm³, a reading that would instantly eliminate it from consideration as natural chalcedony. The test’s only limitation involves resin-filled specimens where the treatment occupies less than 10% of the stone’s volume; in these cases, the overall density may remain close enough to the natural range to avoid detection, necessitating additional verification methods.

Our jade factory includes certified SG measurements in every batch documentation package we provide to wholesale customers. This practice serves dual purposes: it demonstrates our commitment to transparency while establishing a baseline that buyers can use to spot-check incoming shipments against our certified values.

Technique 3: Thermal Conductivity Touch Test and Professional Verification

Quartz possesses significantly higher thermal conductivity (approximately 12 W/m·K) compared to organic polymers like epoxy resins (roughly 0.2 W/m·K) or plastic materials. This fifty-fold difference in heat transfer capability creates a tactile signature that experienced gemologists can detect through the simple “touch test.” Natural agate feels noticeably cold when first contacted because it rapidly conducts heat away from the skin, and it takes several seconds to warm to body temperature. Resin-filled agate or completely synthetic plastic imitations feel warm almost immediately due to their insulating properties, which trap the warmth from your hand rather than dispersing it.

For professional verification beyond subjective touch assessment, gemological thermal conductivity probes provide objective measurements. These handheld devices, commonly called “gem testers,” apply a small heated element to the stone’s surface and measure how quickly the material draws heat away from the probe. The instrument displays a reading typically calibrated for diamond versus simulant testing, but the same principle applies to distinguishing quartz from glass or polymer materials. A genuine agate specimen will register in the “gemstone” or “quartz” range, while resin composites trigger the “simulant” or “glass” indicator.

The touch test costs nothing and can be performed discreetly during initial supplier negotiations, making it valuable for preliminary screening. However, ambient temperature affects accuracy—cold storage or air-conditioned showrooms can make resin feel cooler than normal, while warm display lights might heat natural stones. Therefore, we recommend using this method as a supplementary check rather than a primary authentication tool. At trade shows and buying trips, JADE MAGO representatives carry pocket-sized thermal conductivity testers that provide verification within three seconds, allowing rapid screening of hundreds of specimens without laboratory delays.

Technique 4: Mohs Hardness Scratch Testing on Inconspicuous Areas

The Mohs hardness scale quantifies a mineral’s resistance to abrasion, with agate ranking between 6.5 and 7—harder than common steel but softer than materials like topaz or corundum. This property provides a straightforward authentication method: a steel knife blade (hardness approximately 5.5) should not be able to scratch genuine agate, while the agate itself will easily scratch common window glass (hardness 5.5). The test’s destructive nature requires careful application on inconspicuous areas such as the base of a cabochon, the interior of a bead hole, or the back surface of a flat specimen.

To perform the scratch test, select a sharp steel implement and attempt to make a mark on an unexposed portion of the stone using moderate pressure. If the blade leaves a permanent white scratch that cannot be wiped away, the material is softer than steel and therefore cannot be quartz—it might be calcite (hardness 3), resin (hardness 2-3), or soft glass. Conversely, test the specimen against window glass by drawing a line with the stone; genuine agate should cut the glass surface. The combination of these two observations—cannot be scratched by steel, can scratch glass—confirms the material’s hardness is consistent with chalcedony.

Several important caveats apply to this technique. First, high-quality resin-filled specimens may have authentic quartz as the host material, with only the fractures containing polymer; in these cases, scratch testing the unfilled areas would yield false negative results (appearing to confirm authenticity despite the treatment). Second, some modern glass formulations achieve hardness levels approaching 6.5 through chemical tempering, potentially creating ambiguous results. Third, the test leaves permanent marks on softer materials, which can damage merchandise and create liability issues if performed on consignment goods. For these reasons, we classify scratch testing as a “backup verification” method to be used when other techniques yield inconsistent results, not as a primary screening tool for valuable wholesale lots.

Technique 5: Refractive Index Measurement Using Professional Refractometry

Refractive index represents the most definitive optical test for gemstone identification because it reflects the fundamental relationship between light velocity in vacuum versus light velocity in the material. Agate exhibits a very specific RI of 1.530 to 1.543, typically producing a “spot reading” of 1.53 on a standard gemological refractometer. This narrow range allows clear differentiation from common simulants: most glass varieties show RIs between 1.47 and 1.70 (depending on chemical composition), while epoxy resins typically measure around 1.50.

The testing procedure requires a gemological refractometer, a high-refractive-index contact liquid (usually RI = 1.81), and a flat, polished surface on the specimen. Apply a small drop of the RI liquid to the refractometer’s hemispherical glass element, place the stone’s polished surface face-down in contact with the liquid, and observe the shadow edge through the instrument’s eyepiece while using the built-in light source. The position of the shadow line on the calibrated scale directly indicates the specimen’s refractive index. For cryptocrystalline materials like agate, you’ll typically observe a single reading around 1.53 rather than the double readings (birefringence) seen in coarser quartz crystals.

The International Gem Society identifies RI verification as a primary definitive test for chalcedony varieties, noting that the combination of specific gravity and refractive index measurements provides near-certain identification in the absence of sophisticated treatments [Reference Link to IGS source]. However, this technique faces limitations with resin-filled specimens when the polymer’s RI has been carefully matched to quartz values. Some high-end counterfeiters use specially formulated epoxies with RIs adjusted to 1.54, which can fool refractometer testing if the measurement happens to be taken across a filled fracture rather than solid quartz. This vulnerability explains why we employ RI testing as part of a multi-method approach rather than relying on any single technique.

Professional refractometers suitable for gemstone testing cost between $400 and $1,200, representing a significant investment for small-scale buyers. However, many gemological laboratories offer individual stone testing services for $15-30 per specimen, making this option accessible for verifying high-value purchases even without owning the equipment. At our jade processing facility, we maintain calibrated refractometry equipment as part of our quality assurance protocol, and we include RI measurements in the certification documentation for wholesale customers who request comprehensive analytical data.

The 9 Industrial Counterfeiting Technologies You’re Competing Against

Understanding the sophisticated treatment processes employed by modern counterfeiters provides essential context for why traditional inspection methods have become obsolete. These nine technologies represent a complete industrial workflow that transforms low-grade chalcedony into convincing imitations of premium natural agate. The investment required for this equipment—often exceeding $200,000 for a complete production line—demonstrates the scale and professionalism of today’s treatment operations. As a jade factory with decades of gemstone manufacturing experience, JADE MAGO has studied these processes not to replicate them, but to develop detection protocols that protect our customers from purchasing misrepresented materials.

The following technical analysis draws from peer-reviewed gemological research, industry trade publications, and our own laboratory examinations of seized counterfeit specimens. Each process description includes the scientific rationale, typical equipment specifications, and the specific visual or measurable signatures that betray its use. This knowledge transforms you from a passive buyer relying on supplier honesty into an informed quality control professional capable of independent verification.

.webp)

Technology Cluster 1: Chemical Infiltration Systems

The foundation of high-simulation agate treatment lies in controlling how chemical agents penetrate the stone’s microstructure. Unlike simple surface dyeing, these infiltration techniques achieve color penetration that extends throughout the specimen’s entire volume, creating the illusion of natural mineral pigmentation.

Porosity Selection and Pre-treatment Engineering

The success of chemical infiltration depends entirely on the interstitial space between microcrystalline quartz fibers that comprise chalcedony’s structure. Natural agate ranges from nearly non-porous (in high-quality specimens with tightly interlocked crystals) to moderately porous (in specimens with larger void spaces between fiber bundles). Treatment facilities begin by screening raw material using air permeability tests or mercury intrusion porosimetry to identify stones with porosity levels between 5% and 15%—porous enough to accept chemical agents but dense enough to retain structural integrity during processing.

Pre-treatment often involves acid washing with dilute hydrochloric or citric acid solutions to remove surface oxidation, organic residues, and calcium carbonate deposits that could impede dye penetration. According to research published in Gems & Gemology, this cleaning step can increase color uptake by 40-60% compared to untreated surfaces [Reference Link to GIA source]. Some operators also employ ultrasonic cleaning in alkaline solutions to open micro-fractures and enhance porosity artificially. The most sophisticated facilities use X-ray computed tomography (CT scanning) to map internal porosity distribution three-dimensionally, allowing them to predict exactly how dyes will penetrate and to select optimal treatment parameters for each batch.

This initial selection process explains why not all low-grade agate enters the treatment pipeline. Material with porosity below 3% resists chemical penetration regardless of processing intensity, while specimens exceeding 20% porosity tend to accept dye too readily, producing unnaturally saturated, uniform color rather than the subtle gradations found in natural stones. The “Goldilocks zone” of 5-15% porosity requires specific geological conditions during formation, which is why certain agate deposits in Brazil, Uruguay, and China have become preferred sources for treatment operations.

Vacuum-Pressure Impregnation for Deep Color Penetration

Traditional dyeing methods apply colored solutions to a stone’s surface and rely on capillary action to draw pigments into pores—a slow, shallow process that rarely penetrates beyond 2-3 millimeters. High-simulation techniques instead employ vacuum-pressure impregnation systems that force coloring agents deep into the stone’s core, achieving penetration depths of 10-20 millimeters in specimens with appropriate porosity. This process occurs in two distinct phases, each requiring specialized industrial equipment.

The vacuum phase removes air from the stone’s internal voids. Operators place pre-cleaned specimens in a stainless steel autoclave chamber and evacuate the atmosphere to pressures of 0.01-0.001 atmospheres (roughly 1% of normal air pressure) using rotary vane vacuum pumps. This step typically runs for 2-4 hours, depending on specimen size and porosity characteristics. As air evacuates from the stone’s pores, it creates a negative pressure differential that primes the material to accept the subsequent dye solution. Incomplete vacuum evacuation leaves residual air pockets that prevent uniform color distribution, creating the “spotty” appearance characteristic of low-quality dyed agate.

Following evacuation, operators flood the chamber with the coloring solution—typically iron nitrate, iron sulfate, or organic dye compounds dissolved in water or alcohol carriers. The pressure phase then applies 50-150 PSI of hydraulic or pneumatic pressure, physically forcing the liquid deep into the stone’s structure. Research documented in Gems and Gemology (2018) confirms that this combination of vacuum pre-treatment and pressure application achieves penetration depths 8-12 times greater than ambient-pressure soaking methods . Treatment duration varies from 12 hours for moderately porous material to 72 hours for denser specimens requiring extreme infiltration.

The chemical composition of the impregnation solution determines not just color but also detection resistance. Simple organic dyes (like those used in fabric coloring) fade under UV exposure and can be identified through spectroscopic analysis. More sophisticated operations use metal salt solutions—particularly iron compounds—that undergo subsequent thermal conversion into stable mineral pigments indistinguishable from natural colorants. This transition from chemical infiltration to thermal modification represents the bridge between our first and second technology clusters.

Chemical Concentration Gradients for Banding Simulation

Natural agate’s distinctive banding results from rhythmic variations in silica precipitation chemistry over geological time scales, creating parallel layers with different trace element compositions, crystal orientations, or inclusion densities. Replicating this feature represents the most challenging aspect of high-simulation treatment because uniform dye application produces flat, monotonous color rather than the complex stratification seen in natural specimens. Advanced treatment protocols address this problem through controlled concentration gradients—deliberate variations in dye solution strength that create artificial “bands” mimicking natural patterns.

The gradient approach employs sequential soaking cycles with progressively diluted or concentrated chemical solutions. For example, an operator might begin with a 5% iron nitrate solution for the initial vacuum-pressure cycle, followed by drainage and re-treatment with a 2% solution, then a final cycle with 0.5% concentration. Because the stone’s outer layers receive exposure to all three concentrations while the core receives only the most penetrating first treatment, this creates a radial color gradient from surface to center. By selectively masking portions of the stone with wax or silicone coatings between cycles, technicians can control which areas receive which concentration levels, building up artificial “bands” in patterns that resemble natural deposition sequences.

The Journal of Gemmology published research from Gem-A documenting that concentration gradient techniques can produce banding patterns that fool visual inspection and even resist detection under standard gemological microscopy [Reference Link to Gem-A source]. The diagnostic indicators that betray this treatment include overly regular band spacing (natural bands exhibit chaotic, non-periodic patterns), banding that doesn’t follow the stone’s external morphology (natural bands form parallel to growth surfaces), and chemical analysis showing identical trace element ratios across supposedly different “growth zones.” At JADE MAGO, we’ve developed proprietary microscopic examination protocols that identify the subtle “pooling” patterns where gradient-applied dyes accumulate in higher-porosity layers, creating faint halos that don’t occur in naturally banded material.

Technology Cluster 2: Thermal Modification Processes

Chemical infiltration alone cannot create stable, permanent color in treated agate. The metal salt solutions used in vacuum-pressure impregnation remain water-soluble and vulnerable to leaching unless they undergo thermal conversion into stable mineral phases. This second technology cluster transforms soluble chemical compounds into insoluble mineral pigments through carefully controlled heating and cooling cycles.

Oxidizing Thermal Transformation (Heat Treatment)

After chemical impregnation, stones enter high-temperature furnaces where controlled heating dehydrates the infiltrated metal salt solutions and triggers oxidation reactions that convert soluble compounds into stable mineral pigments. The most common transformation involves iron salts: iron nitrate [Fe(NO₃)₃] or iron sulfate [FeSO₄] converts to hematite [Fe₂O₃], the same iron oxide mineral that provides the red-to-orange coloration in naturally pigmented carnelian and sard varieties of chalcedony.

The thermal transformation process requires precise temperature control within specific ranges. Research published in the Journal of Materials Science documents that iron salt conversion to hematite occurs optimally between 450°C and 600°C in oxidizing atmospheres [Reference Link to Journal of Materials Science]. Below 400°C, the reaction proceeds too slowly for commercial production timelines, requiring treatment cycles exceeding 48 hours. Above 650°C, the chalcedony structure itself begins to undergo phase transitions and textural changes that damage the stone’s optical properties, creating a chalky or cloudy appearance rather than the desired glassy luster.

Treatment furnaces typically employ programmable temperature controllers that ramp heating rates at 50-100°C per hour to prevent thermal shock fracturing. The stones reach the target temperature range and stabilize for 6-12 hours, allowing complete dehydration and oxidation throughout their volume. Atmosphere control is critical: oxygen-rich environments promote hematite formation and vibrant red colors, while oxygen-depleted conditions can produce magnetite [Fe₃O₄] instead, yielding black or dark gray coloration. Some facilities bubble compressed air through the furnace chamber or inject pure oxygen to ensure consistent oxidizing conditions.

The thermal transformation’s permanence poses both advantages and challenges for detection. Unlike unstable organic dyes that fade or leach out, hematite-based coloration is chemically identical to natural pigmentation and exhibits excellent stability under normal wearing conditions. However, this same stability makes the treatment nearly impossible to reverse or remove, which is why misrepresented thermally treated material causes such severe financial consequences when discovered—the stones cannot be “fixed” or reprocessed into legitimate natural specimens.

Controlled Cooling Curves (Annealing)

Rapid temperature changes induce thermal stress in chalcedony’s microcrystalline structure due to differential expansion and contraction rates between the stone’s surface and core. If a specimen at 550°C encounters ambient air temperature (approximately 20°C), the outer layers contract rapidly while the interior remains expanded, creating mechanical stress that manifests as a network of fine cracks called “crazing.” These surface fractures scatter light diffusely, destroying the stone’s characteristic waxy or vitreous luster and creating a dull, chalky appearance that immediately reveals heat treatment.

Professional treatment operations prevent crazing through controlled cooling curves, also called annealing protocols. After the high-temperature oxidation phase, programmable furnaces slowly reduce temperature at rates typically between 20°C and 50°C per hour, allowing the stone’s entire volume to contract uniformly. The cooling rate must be calibrated to the specimen’s size and thickness: larger stones with greater thermal mass require slower cooling to prevent core-to-surface temperature gradients, while smaller beads or cabochons can tolerate faster rates.

Kurt Nassau’s seminal text Gemstone Enhancement documents that proper annealing preserves not only structural integrity but also optical quality, maintaining the “watery” or “greasy” luster that characterizes high-grade natural agate [Reference Link to Nassau reference]. The cooling phase typically extends 12-24 hours for commercial treatment batches, with the final approach to room temperature proceeding especially slowly (perhaps 10°C per hour below 200°C) to eliminate residual stress. Some facilities employ two-stage cooling: rapid descent from peak temperature to 300°C, followed by extremely slow cooling through the critical 300-100°C range where quartz undergoes structural transitions.

Detection of heat treatment through cooling defects requires careful examination under magnification. Incomplete annealing produces characteristic “stress disks” visible under crossed polarizing filters, where residual mechanical stress creates birefringence patterns that don’t correspond to the stone’s natural crystalline structure. Our jade processing laboratory employs polariscope examination as a standard screening technique specifically to identify these stress patterns, which are absent in never-heated natural specimens.

Technology Cluster 3: Optical Deception Engineering

The most sophisticated treatment technologies target the stone’s optical properties directly, using techniques borrowed from industrial optics and materials science to manipulate how light interacts with the treated material. These processes create visual effects that can defeat not only naked-eye inspection but even some laboratory testing protocols.

Refractive Index Matching (Polymer Injection)

Natural agate frequently contains fractures, fissures, or vugs (small cavities) that scatter light and reduce transparency. These structural imperfections appear as white or cloudy areas that decrease the stone’s value and visual appeal. Polymer injection treatment fills these voids with synthetic resins carefully formulated to match chalcedony’s refractive index (RI ≈ 1.54), rendering the fractures nearly invisible and creating the appearance of higher clarity.

The process begins with vacuum treatment similar to dye impregnation, evacuating air from the stone’s internal fractures. Instead of colored dye solutions, however, operators introduce liquid epoxy resins or polyester compounds with optical constants matched to quartz. According to the International Gem Society, epoxies can be formulated with RIs ranging from 1.48 to 1.58 by varying the monomer composition and polymerization additives . For agate treatment, formulators target RI values of 1.53-1.54, creating minimal optical discontinuity at the resin-quartz interface.

After infiltration, the polymer undergoes curing through thermal activation (heat-cure resins) or UV radiation exposure (photo-cure resins), transforming from liquid to solid and permanently filling the fractures. The cured resin’s refractive index match means that light passes through the filled fractures with minimal reflection or scattering, making them invisible under normal viewing conditions. The treatment can improve apparent clarity from translucent or semi-translucent grades to near-transparent, substantially increasing market value.

Detection requires identifying the subtle signatures that betray polymer presence. Under magnification, filled fractures often show trapped gas bubbles that appear as tiny spheres aligned along the fracture plane—these never occur in solid quartz. UV fluorescence testing can reveal polymer content: many epoxy formulations exhibit blue-white or yellow fluorescence under long-wave UV (365nm), while natural chalcedony is typically inert. The most definitive test employs Fourier-transform infrared spectroscopy (FTIR), which identifies characteristic absorption bands from C-H and C-O bonds in organic polymers; however, this requires laboratory equipment beyond most buyers’ access. At JADE MAGO, we routinely perform UV fluorescence screening on all wholesale acquisitions specifically to detect this treatment category before material enters our production workflow.

Transition Metal Doping for “Fleshiness” Simulation

Natural Nanhong agate from China exhibits a distinctive optical quality called “fleshiness”—a specific type of opacity with warm, organic-looking texture that results from dense submicroscopic inclusions scattering light internally. This quality commands premium prices in Asian markets, making it a prime target for simulation. High-end treatment operations have developed transition metal doping techniques that mimic this characteristic turbidity through controlled precipitation of metallic compounds within the stone’s structure.

The process combines multiple metal salts during vacuum-pressure impregnation. While iron compounds provide base coloration, trace additions of manganese or chromium salts create secondary mineral phases with different optical properties. Research documented in Acta Petrologica et Mineralogica shows that manganese oxide precipitates form submicroscopic particles that scatter light at specific wavelengths, creating the warm, diffuse quality associated with natural inclusions [Reference Link to Acta Petrologica]. The key technical challenge involves controlling particle size: precipitates must remain smaller than visible wavelengths (below 400 nanometers) to avoid creating obvious spots or cloudiness, yet large enough to effectively scatter light.

Treatment protocols typically employ manganese sulfate (MnSO₄) or chromium nitrate [Cr(NO₃)₃] at concentrations of 0.1-0.5%—far lower than the iron salt concentrations used for primary coloration. During subsequent heat treatment, these compounds undergo thermal decomposition and oxidation, forming manganese dioxide (MnO₂) or chromium oxide (Cr₂O₃) nanoparticles distributed throughout the stone’s volume. The resulting material exhibits the desired opacity and warm character, with light-scattering properties that closely approximate natural Nanhong specimens.

Detection of transition metal doping requires chemical analysis beyond standard gemological testing. X-ray fluorescence (XRF) spectroscopy can identify manganese or chromium content and quantify concentration levels, but distinguishing between natural trace elements and treatment additions requires comparison against databases of untreated specimens from known localities. Advanced techniques like laser ablation inductively coupled plasma mass spectrometry (LA-ICP-MS) can map elemental distribution three-dimensionally, revealing the uniform, treatment-characteristic distribution pattern versus the heterogeneous, growth-zone-controlled distribution in natural stones. These analytical methods remain available primarily to research laboratories and certification facilities rather than commercial buyers, which is why JADE MAGO maintains relationships with accredited gemological laboratories that can perform these specialized tests on our behalf.

Legal Compliance – The Gemstone Labeling Standards That Protect Your Business

Beyond the technical challenges of identifying treated agate lies an equally critical dimension: legal compliance with international gemstone disclosure regulations. Many wholesale buyers focus exclusively on authentication while overlooking the fact that even correctly identified treatments carry mandatory labeling requirements that, if violated, expose businesses to lawsuits, forced refunds, and regulatory penalties. The global gemstone trade operates under a patchwork of national regulations and industry standards that collectively establish a single principle: consumers have the legal right to know what they’re purchasing, and any material treatment affecting value must be disclosed.

For agate wholesale operations, compliance failures typically occur not from intentional fraud but from inadequate documentation in the supply chain. A Chinese manufacturer might apply vacuum-pressure dyeing and accurately label shipments as “treated,” but if that designation doesn’t transfer through all subsequent transactions—from importer to distributor to retailer—the final consumer receives misrepresented merchandise. The liability question then becomes: who bears responsibility for the non-disclosure? Increasingly, courts and regulatory agencies hold all parties in the supply chain accountable, meaning wholesale buyers must implement verification and documentation protocols that protect against both upstream fraud and downstream liability.

Global Authority Requirements and Enforcement Mechanisms

Four major regulatory frameworks govern gemstone disclosure in international trade, each with distinct jurisdictional reach and enforcement approaches. Understanding these requirements is essential because agate wholesale transactions frequently cross national borders, potentially triggering obligations under multiple legal systems simultaneously.

FTC Regulations: The United States Standard

The Federal Trade Commission’s Jewelry Guides, codified at 16 CFR Part 23, establish the baseline disclosure requirements for gemstone sales in the United States market. Section 23.24 specifically addresses gemstone treatments, mandating disclosure if a treatment “(1) is not permanent, (2) creates special care requirements, or (3) has a significant effect on the stone’s value.” For agate, this means vacuum-pressure dyeing, heat treatment, and polymer impregnation all require disclosure because they substantially affect market value—natural specimens command 300-500% price premiums over treated equivalents in comparable sizes and qualities.

The FTC regulations define non-compliance as an “unfair or deceptive trade practice” subject to civil penalties. While the FTC rarely prosecutes individual transactions, they aggressively pursue pattern violations and have levied fines exceeding $1 million against jewelry retailers who systematically sold treated gemstones without disclosure. More commonly, FTC violations create liability in civil litigation: consumers who discover they purchased misrepresented gemstones can sue for rescission (full refund plus legal costs) or damages based on the value difference between what they paid and the actual market value of treated material.

For B2B wholesale transactions, FTC guidelines require that commercial invoices specify treatment status using clear, unambiguous language. Phrases like “enhanced,” “improved,” or “optimized” without explicit treatment descriptions are considered inadequate and potentially deceptive. The proper disclosure format uses direct terminology: “Dyed and heat-treated agate” or “Natural agate, polymer-impregnated to enhance clarity.” At JADE MAGO, all commercial invoices include a dedicated “Treatment Status” field that explicitly states either “Natural, untreated” or describes specific processes applied, ensuring our wholesale customers receive documentation that satisfies FTC requirements for downstream transactions.

CIBJO: The International Standard-Setting Body

The World Jewellery Confederation (CIBJO) publishes the “Blue Books”—industry reference standards covering nomenclature, grading, and disclosure for all major gemstone categories. While CIBJO holds no direct legal enforcement authority, their standards have been adopted by trade associations, auction houses, and insurance companies worldwide, making them effectively mandatory for high-value transactions and international trade. The Coloured Gemstone Blue Book requires that the word “Treated” appears with equal prominence to the gemstone name whenever non-traditional treatments have been applied.

CIBJO classifications use a tiered approach distinguishing “traditional” treatments (considered normal for a particular gemstone type) from “non-traditional” treatments requiring explicit disclosure. For agate and chalcedony, heat treatment without chemical additives is classified as traditional and may be disclosed optionally, while dyeing, impregnation, and polymer filling are non-traditional and require mandatory disclosure. This creates an important nuance: heat-only treatment of Brazilian agate to enhance existing red tones doesn’t necessarily require the “Treated” designation under CIBJO standards, though it would still require disclosure under FTC rules when sold in the US market.

The practical impact of CIBJO standards emerges most clearly in auction contexts and insurance valuation. Major auction houses like Christie’s and Sotheby’s require CIBJO-compliant documentation for gemstone lots, rejecting consignments that lack proper treatment disclosure. Similarly, insurance companies increasingly reference Blue Book standards when determining coverage and claim settlements, potentially denying claims for “natural” gemstones later revealed to be treated if the original documentation didn’t meet CIBJO disclosure requirements. For wholesale buyers supplying high-end retail or collector markets, ensuring CIBJO-compliant documentation at the point of purchase protects against these downstream complications.

European Union Consumer Protection Regulations

The European Union’s consumer protection framework, encompassing directives on unfair commercial practices and consumer rights, requires complete material disclosure on all invoices and point-of-sale documentation. EU regulations approach gemstone disclosure from a consumer protection angle rather than industry self-regulation, meaning violations can trigger mandatory refunds, “misleading advertising” fines assessed by national consumer protection agencies, and in severe cases, criminal fraud charges under member state laws.

The EU’s Product Liability Directive (85/374/EEC) and subsequent amendments establish strict liability for defective products, with “defect” defined to include any product that fails to provide the safety or characteristics “which a person is entitled to expect.” Courts in several EU member states have ruled that undisclosed gemstone treatments constitute defects under this standard because consumers reasonably expect “natural” designations to mean untreated unless otherwise specified. A 2024 case in Germany resulted in a €120,000 judgment against an importer who sold polymer-filled agate as “natural” despite having received accurate treatment disclosure from the Chinese supplier—the court found the importer liable for failing to verify and pass along this information to retail customers.

For agate wholesale transactions destined for EU markets, best practice requires not just invoice disclosure but retention of complete documentation chains tracing treatment status from mine or cutting facility through all intermediate transactions. EU customs authorities increasingly request this documentation during importation, and failure to provide it can result in detained shipments, additional testing at importer expense, and potential exclusion from the market if treatment status cannot be verified. JADE MAGO maintains a digital documentation system that tracks each production batch from raw material acquisition through final shipment, generating certifications that satisfy EU traceability requirements and protect our European wholesale customers from regulatory complications.

AGTA: The B2B Professional Standard

The American Gem Trade Association, while not a governmental regulatory body, establishes the de facto standards for professional B2B transactions in the gemstone industry through its Code of Ethics and standardized treatment disclosure codes. AGTA members—representing the majority of significant wholesale dealers and manufacturers in the US market—commit to using standardized terminology on all commercial invoices and laboratory reports: “D” for dyeing, “H” for heating, “I” for impregnation, and “N” for natural/untreated.

The AGTA system’s value lies in its clarity and universal recognition within the trade. Rather than ambiguous phrases or treatment descriptions requiring interpretation, the single-letter codes provide unambiguous communication. An invoice listing “Agate (D+H)” immediately informs all parties that the material has been dyed and heat-treated, while “Agate (N)” certifies untreated status. This standardization prevents the linguistic confusion that often arises in international trade where terminology may carry different implications across languages and cultures.

AGTA membership requires adherence to these disclosure standards, with violations potentially resulting in suspension or expulsion from the association—a serious professional consequence given AGTA’s role in organizing major trade shows and facilitating industry networking. More importantly, AGTA treatment codes have been recognized in commercial arbitration and litigation as establishing industry custom and practice, meaning courts may reference AGTA standards when determining whether disclosure obligations were met in disputes between trade parties. For wholesale buyers and sellers, adopting AGTA coding on commercial documentation provides legal defensibility regardless of association membership status.

The Invoice Language Trap: Identifying Inadequate Disclosure

The most common compliance failure in agate wholesale transactions involves inadequate or deliberately ambiguous invoice language designed to obscure treatment status while technically avoiding outright falsehood. Sophisticated suppliers have developed terminology that sounds transparent but actually conveys no actionable information, leaving buyers legally exposed when they resell material based on assumptions rather than explicit certifications.

Dangerous Terminology That Creates Liability

Several phrases frequently appear on gemstone invoices despite providing insufficient disclosure under FTC, CIBJO, and EU standards. “Enhanced agate” represents perhaps the most problematic example: the term “enhanced” could mean dyeing, heating, impregnation, irradiation, surface coating, or any combination thereof. Without specification of which enhancement processes were applied, the buyer cannot make informed purchasing decisions or provide adequate disclosure to downstream customers. Similarly, “improved quality” or “optimized color” describes outcomes rather than processes, failing to communicate the specific treatments that produced those outcomes.

“Color-treated” appears more specific but remains inadequate because it doesn’t distinguish between dyeing (impregnation with colored chemicals) and heat treatment (modification of existing mineral content through temperature changes)—two processes with vastly different stability characteristics and value implications. Buyers receiving “color-treated” invoices cannot determine whether the color will fade under UV exposure (characteristic of some organic dyes) or remain permanent (characteristic of heat-converted iron oxides), information essential for quality assurance and customer advisement.

Perhaps most insidiously, some suppliers use technically accurate but incomplete disclosures that satisfy minimal legal requirements while concealing the full extent of treatment. An invoice stating “heat-treated agate” might be literally true while omitting that the material was also dyed before heating. Because heat treatment alone carries less value impact than the dye-plus-heat combination, this partial disclosure manipulates price negotiations in the supplier’s favor while creating downstream liability for buyers who reasonably relied on the invoice description.

Safe Terminology That Provides Legal Protection

Compliant disclosure uses specific, process-oriented language that identifies each treatment applied and, when relevant, the sequence of treatments. “Dyed and heat-treated agate” clearly communicates that chemical colorants were introduced and subsequently thermally fixed. “Polymer-impregnated for clarity enhancement” specifies both the treatment (impregnation) and the material used (polymer), allowing buyers to assess stability and care requirements.

The gold standard for disclosure combines treatment identification with supporting laboratory certification. An invoice stating “Natural, untreated agate—see attached GIA report #12345678” provides third-party verification of treatment status, shifting liability for misrepresentation to the issuing laboratory (which carries professional indemnity insurance for exactly this purpose). For high-value wholesale transactions exceeding $10,000, the cost of laboratory certification (typically $75-200 per stone or lot) represents reasonable risk management given the potential liability exposure from undisclosed treatments.

JADE MAGO employs a two-tier disclosure system on all commercial invoices. The primary treatment field uses AGTA standardized codes (N, D, H, I, or combinations) for immediate clarity. A secondary “Treatment Detail” field provides written descriptions such as “No treatments applied; natural color and clarity” or “Vacuum-pressure dyed with iron compounds; heat-treated at 520°C; no polymer filling.” This redundant approach ensures compliance across multiple regulatory frameworks while providing customers with both the condensed information needed for inventory systems and the detailed descriptions required for consumer-facing labeling.

Real-World Compliance Failure: The €120,000 European Case Study

The 2024 German court case mentioned earlier provides instructive details about how compliance failures create financial liability despite good-faith business practices. The defendant, a mid-sized jewelry importer operating primarily through online retail channels, purchased 3,000 agate cabochons from a Chinese supplier in 2023. The commercial invoice described the material as “agate, enhanced color,” with per-piece pricing at $12—approximately 60% below typical natural agate market rates. The importer’s purchasing manager, unfamiliar with gemstone-specific terminology, interpreted “enhanced color” as referring to superior natural color rather than treatment processes.

The importer listed the stones on their e-commerce platform as “natural agate” without further qualification, selling approximately 2,400 pieces to consumers across Germany, France, and Netherlands at retail prices of €45-60. In early 2024, a customer submitted several purchased stones to an independent laboratory for authentication as part of an insurance valuation. Laboratory testing revealed vacuum-pressure dyeing and heat treatment, leading the customer to file a complaint with Germany’s Federal Ministry of Justice and Consumer Protection alleging fraudulent misrepresentation.

The regulatory investigation uncovered that the Chinese supplier had actually provided accurate disclosure—”enhanced color” does indicate treatment in Chinese gemstone trade terminology—but the importer had failed to verify this meaning or seek clarification before creating consumer-facing product descriptions. The court ruled that (1) the importer bore responsibility for understanding industry terminology when making wholesale purchases, (2) the price differential should have prompted additional due diligence, and (3) the failure to obtain and review laboratory certification for material priced significantly below natural equivalents constituted negligence.

The judgment required the importer to (1) refund all customers who purchased the treated agate and requested refunds (approximately 800 stones at an average €52 retail price = €41,600), (2) pay €45,000 in administrative fines to consumer protection authorities, (3) cover €32,000 in plaintiff legal costs and court fees, and (4) publish corrective notices on their website and social media channels. The total financial impact exceeded €120,000, transforming what appeared to be a profitable purchase of competitively priced material into a devastating loss that ultimately forced the company into bankruptcy proceedings.

This case illustrates three critical compliance principles for agate wholesale operations. First, ambiguous terminology on supplier invoices creates liability for buyers regardless of supplier intent—the obligation to verify and clarify rests with the purchaser. Second, price signals provide actionable information: material priced substantially below natural equivalents warrants laboratory verification before resale. Third, documentation requirements extend beyond initial purchase to encompass the entire supply chain through final consumer sale, meaning wholesale buyers must implement systems ensuring treatment status transfers accurately through all subsequent transactions.

Why JADE MAGO’s 65-Year Jade Processing Legacy Guarantees Transparency

After examining the technical sophistication of modern counterfeiting and the complex regulatory landscape governing gemstone disclosure, a reasonable question emerges: how can wholesale buyers identify suppliers who consistently provide authentic, properly documented material? The answer lies not in trusting supplier claims but in evaluating objective indicators of operational transparency and technical competence. At JADE MAGO, our 65-year history of jade processing and gemstone manufacturing has been built on a foundation of verifiable quality standards that buyers can independently confirm rather than simply accept on faith.

.webp)

Technical Infrastructure as Transparency Indicator

Our jade factory’s commitment to natural, untreated gemstones isn’t merely ethical positioning—it’s embedded in our physical infrastructure and operational workflows. Unlike treatment-focused facilities that invest in vacuum chambers, high-temperature furnaces, and chemical impregnation systems, JADE MAGO’s manufacturing equipment emphasizes precision cutting, advanced polishing, and non-destructive quality assessment. Our facility houses spectroscopic analysis equipment including FTIR and Raman spectrometers that detect polymer content and identify heat-treatment signatures, but these instruments serve quality control purposes rather than treatment optimization.

This infrastructure difference creates observable verification opportunities for wholesale customers. Factory tours reveal the absence of treatment-specific equipment: no autoclave chambers for vacuum-pressure impregnation, no industrial furnaces capable of reaching the 450-600°C temperatures required for iron salt conversion, no chemical storage areas housing the metal salt solutions used in gradient dyeing. The presence or absence of this equipment provides more reliable information than verbal assurances because capital investment in treatment infrastructure represents long-term strategic commitment that cannot be easily concealed or misrepresented.

Beyond equipment verification, our manufacturing processes incorporate multiple independent quality checkpoints where treatment detection would occur naturally. Raw material undergoes incoming inspection using UV fluorescence, thermal conductivity testing, and refractometer verification before entering production. Work-in-progress specimens receive spectroscopic screening after cutting but before polishing, catching any treated material that might have passed initial inspection. Finished goods undergo final certification including specific gravity measurement and microscopic examination for dye concentration patterns. This multi-stage protocol means treated material faces multiple independent opportunities for detection, making it effectively impossible for undisclosed treatments to reach wholesale customers.

Certification Documentation and Third-Party Verification

JADE MAGO’s approach to certification documentation differs fundamentally from typical industry practice. Rather than issuing in-house certificates that essentially amount to self-grading, we partner with accredited independent gemological laboratories that provide third-party verification of treatment status for all wholesale orders exceeding $5,000 in value. These laboratory reports accompany commercial invoices and include not just verbal conclusions but the actual analytical data supporting those conclusions: specific gravity measurements, refractive index readings, spectroscopic analysis results, and photomicrographs documenting internal characteristics.

This documentation approach serves dual purposes. First, it provides wholesale customers with independently verifiable evidence they can present to their own customers, regulators, or dispute resolution forums if questions arise about treatment status. Second, it demonstrates our confidence in our own quality control systems—we’re willing to submit material to independent testing because we know it will confirm our representations. Suppliers reluctant to provide third-party certification or who cite cost concerns (laboratory fees typically represent less than 2% of wholesale transaction values for quality material) may be signaling uncertainty about their own products’ authenticity.

Our laboratory relationships extend beyond simple pass/fail certification to include research collaboration on detection methodology. JADE MAGO regularly submits known-treated specimens (acquired from competitors’ products or seized counterfeits) to our laboratory partners for analytical method development, helping refine the protocols that identify increasingly sophisticated treatments. This collaboration benefits the entire industry by advancing detection capabilities while simultaneously providing our wholesale customers with access to cutting-edge authentication services that smaller suppliers cannot offer.

Supply Chain Traceability From Mine to Market

The jade processing industry has historically operated with opaque supply chains where material passes through multiple intermediaries between mine and manufacturer, creating opportunities for treatment insertion at any stage. JADE MAGO has invested substantially in vertical integration and direct sourcing relationships that provide complete traceability from geological source to finished product. For our agate product lines, we maintain direct relationships with mining operations in Brazil, Uruguay, and Inner Mongolia, purchasing rough material directly from extractors rather than through broker networks.

This direct sourcing model enables documentation of geological provenance—we can specify not just “Brazilian agate” but the actual mining district and geological formation, information that allows gemological laboratories to compare trace element profiles against reference databases from known localities. Natural agate from the Salto do Jacuí formation in Rio Grande do Sul, Brazil, exhibits characteristic manganese and iron ratios that differ from material from Uruguay’s Artigas Department or China’s Alxa League deposits. These geochemical fingerprints provide fraud resistance because treated low-grade material from one locality cannot convincingly imitate high-grade natural material from a different geological environment.

Our traceability systems extend beyond geological documentation to encompass complete chain-of-custody records. Each production batch receives a unique identifier linking it to source mine shipment documentation, customs clearance records, incoming inspection reports, manufacturing process logs, and final certification. Wholesale customers can access this complete documentation package through our online portal, providing transparency that supports not just initial authentication but ongoing compliance with increasingly stringent traceability requirements in European and North American markets.

Action Steps: Build Your Agate Wholesale Defense System in 48 Hours

The technical information, legal frameworks, and supplier evaluation criteria presented in this guide provide the knowledge foundation for protecting your gemstone wholesale operations from treatment fraud and compliance liability. However, knowledge alone doesn’t prevent losses—you must translate this understanding into operational protocols that function consistently across all purchasing decisions. The following action steps provide a structured implementation pathway that establishes robust defenses within a 48-hour timeframe.

Professional Upgrade: JADE MAGO Sample Quality Verification Service

For wholesale buyers lacking in-house gemological expertise or laboratory equipment access, JADE MAGO offers complimentary quality verification on sample lots from prospective supplier relationships. Submit 5-10 representative specimens from any wholesale offering you’re considering, and our laboratory will perform the complete five-technique testing protocol plus spectroscopic analysis for polymer content and heat-treatment signatures. You’ll receive a detailed written report within 72 hours documenting all test results, treatment status conclusions, and comparative analysis against our database of known natural and treated specimens.

This service addresses the “asymmetric information” problem that plagues gemstone wholesale markets. Suppliers invest heavily in sophisticated treatment infrastructure and technical expertise, creating knowledge advantages that allow them to misrepresent material to less-informed buyers. By providing access to equivalent analytical capabilities at no cost for sample evaluation, we level the information playing field and enable buyers to make genuinely informed decisions rather than relying on supplier representations or superficial visual assessment.

The sample verification service also functions as supplier credibility screening. Submit samples from multiple potential suppliers and compare the analytical results: suppliers whose material consistently shows natural characteristics across multiple submitted batches demonstrate reliability, while those whose samples reveal undisclosed treatments or inconsistent quality should be eliminated from your supplier network. This comparative approach provides more reliable supplier evaluation than reference checks or facility audits because it assesses actual product quality rather than infrastructure or verbal commitments.

Long-Term Partnership: Customized Agate Wholesale Programs

For established businesses seeking reliable long-term agate sourcing rather than transactional spot purchases, JADE MAGO designs customized wholesale programs aligned with your specific market positioning, quality requirements, and volume needs. These programs provide dedicated production allocations, priority access to premium rough material when it becomes available, and flexible minimum order quantities that accommodate seasonal demand variations without forcing inventory buildups during slow periods.

Customized programs include guaranteed treatment status certification on all material: you specify whether you need “natural untreated only,” “heat treatment acceptable but no dyeing/impregnation,” or any other quality threshold, and we configure our sourcing and quality control protocols to meet those requirements. Every shipment includes complete documentation packages meeting FTC, CIBJO, EU, and AGTA disclosure standards, eliminating the compliance uncertainty that creates downstream liability risk. For high-volume partners (annual purchases exceeding $50,000), we provide dedicated account management and quarterly business reviews that assess quality trends, market developments, and adjustment opportunities.

Program participants receive advance access to new product development including unusual color varieties, specialized cutting styles, and exclusive size ranges not available through standard wholesale channels. This access differential creates competitive advantages for your retail or manufacturing operations: you can offer unique products that competitors cannot easily source, supporting premium pricing and brand differentiation. Contact our wholesale team at [email protected] or +86-185-6617-3973 to discuss program structures and enrollment requirements—most programs activate within 2-3 weeks of initial consultation.

Conclusion: The 2026 Agate Market Demands Proactive Defense

The 67% treatment disclosure failure rate documented in contemporary agate wholesale markets isn’t a temporary anomaly—it represents the new normal created by technological advancement in gemstone processing and increasing price premiums for natural material. As treatment techniques become more sophisticated and harder to detect through simple visual inspection, the burden shifts decisively toward buyers to implement robust verification protocols rather than relying on supplier honesty or industry reputation. The $80,000 average loss per rejected shipment and the €120,000 liability judgment in the European compliance case illustrate that the cost of inadequate verification far exceeds the investment required for proper testing infrastructure.

The five laboratory-grade identification techniques, nine industrial technology insights, and comprehensive legal compliance framework presented in this guide provide you with professional-grade knowledge previously accessible only to gemological laboratories and large-scale dealers with dedicated technical staff. By implementing the 48-hour action plan—field testing protocol adoption, sample verification service utilization, and customized wholesale program exploration—you transform from a passive buyer vulnerable to sophisticated fraud into an informed market participant capable of independent quality verification.

At JADE MAGO, our 65-year commitment to jade processing excellence and natural gemstone aesthetics means we view transparency not as a marketing advantage but as a fundamental operational requirement. Every agate specimen we produce can withstand the most rigorous third-party testing because we invest in geological sourcing quality and manufacturing precision rather than chemical enhancement shortcuts. When you partner with suppliers who maintain this standard—verifiable through factory infrastructure, third-party certification, and supply chain traceability—you don’t just protect individual transactions; you build sustainable competitive advantages based on authentic quality that competitors using treated material cannot replicate.

The agate wholesale market in 2026 rewards informed buyers while punishing those who continue relying on outdated assessment methods. Choose your position deliberately: implement verification protocols today, or accept the statistical likelihood that two-thirds of your purchases contain undisclosed treatments that expose you to both financial loss and legal liability. The tools, knowledge, and support systems exist to succeed in this challenging environment—the only question is whether you’ll deploy them before the next costly mistake rather than after.

FAQ

Why do specific gravity tests sometimes fail to detect resin-filled agate when polymer content is below 10%?

The hydrostatic weighing method’s effectiveness depends on treatment volume relative to total specimen mass. When resin impregnation fills only narrow fractures representing less than 10% of the stone’s volume, the composite specific gravity remains mathematically close to natural agate’s 2.60-2.65 g/cm³ range, creating false negative results.

Defense Strategy: Combine specific gravity measurement with UV fluorescence examination under 365nm long-wave ultraviolet light. Even small quantities of epoxy resin (2-3% by volume) typically exhibit blue-white or yellowish fluorescence that natural chalcedony lacks. This dual-method approach catches both bulk treatments (via SG deviation) and minimal fracture filling (via fluorescence response). For wholesale lots exceeding $10,000, invest in professional FTIR spectroscopy that can detect organic polymer signatures at concentrations below 1%, providing certainty that density testing alone cannot achieve.

Why does the traditional “cool touch” test fail in air-conditioned showrooms?

The touch test relies on the difference in heat transfer between the gemstone and the skin. Natural agate has significantly higher thermal conductivity than resin. However, in heavily air-conditioned showrooms, resin surfaces can become very cold due to prolonged exposure; conversely, under intense display lights, natural agate absorbs heat. This makes subjective touch highly susceptible to misjudgment. It is recommended to use a handheld thermal conductivity meter (Gem Tester) for objective data.

Does it constitute fraud if an invoice only labels “Heat Treated Agate” while concealing “Dyeing” processes?

Yes. According to FTC (Federal Trade Commission) and CIBJO international guidelines, this is classified as “inadequate disclosure.” The market value of dyed agate is typically much lower than that of agate subjected only to physical heat treatment. If a supplier fails to fully disclose all enhancement methods, the buyer has the right to demand a full refund under international trade laws and pursue legal liability for misleading business practices.

-900x375.webp)