Introduction

In modern Jade Processing, “precision” is not a single number, and it is not the same thing as “looks premium.” Buyers often discover this too late—after sampling, when the first production batch shows variation that was never defined, measured, or contractually accepted. This article compares CNC machining and hand carving from a B2B buyer’s perspective: what each method can reliably control, where each method fails, and how to specify requirements so your supplier can quote accurately and deliver consistently.

If you are sourcing for a brand, studio, or cross-border business, the goal is not to pick a “winner.” The goal is to match your design features to a process that can hit your acceptance criteria at a predictable yield and lead time. Once you can describe precision in measurable terms, supplier selection becomes less emotional and far more repeatable—just like good manufacturing.

Table of Contents

What “Precision” Really Means in Jade Processing (Not Just “Looks Sharp”)

Precision = Geometry + Repeatability + Surface Outcome + Risk Control

In Jade Processing, precision should be treated as a bundle of four controls: geometry, repeatability, surface outcome, and risk control. Geometry is what most buyers think of first: dimensions, symmetry, hole positions, groove widths, and feature depth. Repeatability is what production managers care about: how closely item #200 matches item #2 when you run the same design again.

Surface outcome is often misunderstood, because “smooth” can be achieved in multiple ways and at multiple cost levels. A stone can look glossy yet still be dimensionally off, or it can be dimensionally correct yet visually inconsistent due to material variation. Risk control is the hidden part of precision: how the process deals with cracks, inclusions, grain direction, and brittleness so the final delivery is not dominated by unpredictable breakage and rework.

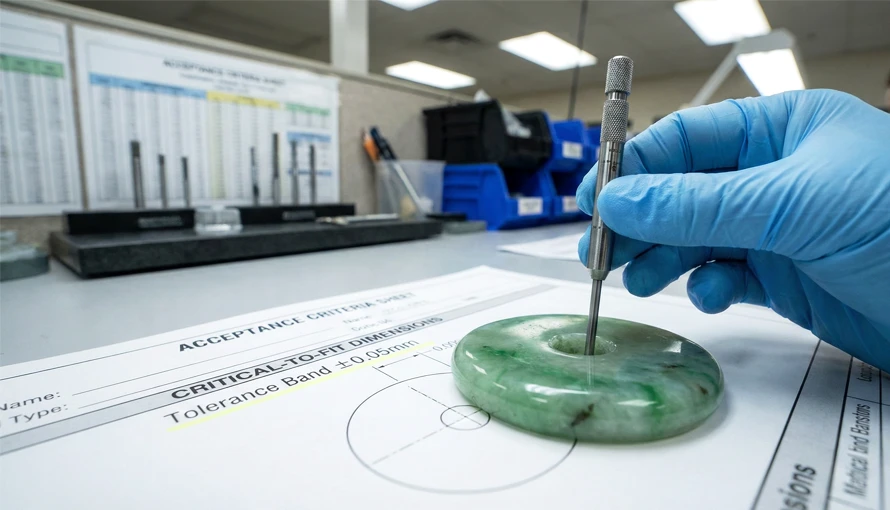

A useful way to make this real is to split requirements into two categories: critical-to-fit and aesthetic-to-judge. Critical-to-fit requirements include things like holes for findings, matching pairs, tight symmetry, and consistent thickness for settings. Aesthetic-to-judge requirements include relief depth, hand-feel, artistic transitions, and how the carving “flows” with the stone’s natural character.

Why “Same File = Same Result” Fails in Natural Stone

Many buyers assume that if a supplier uses CNC, then “same CAD file equals same product.” That logic is reliable in metals and plastics, but jade is not uniform stock, and jade is not just a “hard material.” Two pieces with the same weight and color can behave differently under cutting force, especially when internal structure and micro-fractures vary.

This matters because CNC repeatability is strongest when the material behaves predictably. When the stone behaves unpredictably, CNC can still be used, but process planning must be conservative and quality control checkpoints must be built into the workflow. Without those controls, a supplier can show you a perfect sample and still struggle with production consistency, because sample success does not automatically transfer into high-yield manufacturing.

If you want to reduce disputes, you should treat precision as a range, not a promise of perfection. Your RFQ should define acceptable variation bands and define what happens when natural defects are discovered mid-process. This is not pessimism; it is professional sourcing in natural materials.

Review note for you: If you want, I can insert a “Precision Scorecard” table format here (tolerances, symmetry, surface, defect policy) so the article immediately becomes RFQ-ready.

How CNC Delivers Precision — And Where It Breaks

Why CNC Is Strong on Dimensional Accuracy and Repeatability

CNC excels at geometry because it follows a programmed toolpath with controlled parameters. When the process is stable, CNC can maintain consistent feature-to-feature relationships: hole spacing, concentricity, mirrored symmetry, repeated patterns, and uniform depths across multiple pieces. For buyers who sell standardized SKUs, this is the core value: you can scale without re-interpreting the design every time.

In Jade Processing, CNC also reduces variation introduced by human fatigue and interpretation. A hand carver may intentionally “correct” a line based on their taste, while CNC will execute the same path unless the operator changes the program. This makes CNC especially good for products that must fit accessories, match fixtures, or maintain consistent branding geometry across collections.

However, dimensional accuracy only matters if it is paired with measurement. If a supplier claims “high precision” but cannot show a simple measurement report—such as key dimensions across a batch—then “CNC” becomes marketing rather than manufacturing control. For procurement, the best sign is not the machine; it is the supplier’s ability to define, measure, and report.

CNC Risk Profile: Hidden Defects Can Fail “Suddenly”

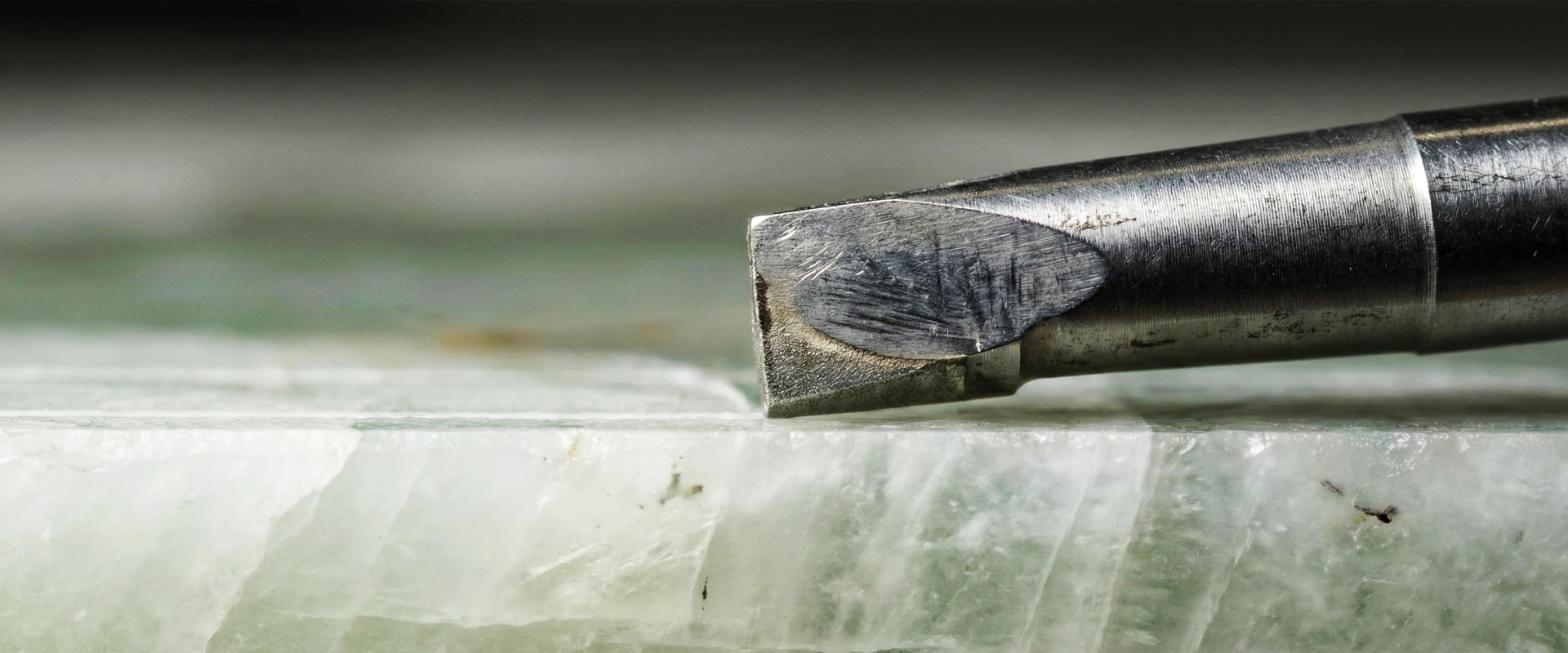

CNC’s biggest weakness in jade is not that it is “less artistic.” The biggest weakness is that CNC applies force consistently, and consistency can be dangerous when the material has hidden weaknesses. A micro-fracture that might be “felt” and avoided in hand carving can become a sudden break during machining, especially if the toolpath or cutting parameters concentrate stress in one area.

This is why some CNC failures look dramatic: a piece can be nearly finished and then crack at a late stage, producing high scrap cost. In production planning, this risk must be managed with conservative roughing, staged cutting, and inspection checkpoints. If a supplier quotes aggressively without building in risk controls, the cost tends to show up later as delays, quality downgrades, or disputes.

For buyers, the practical takeaway is simple: CNC increases repeatability, but it does not eliminate stone risk. If your design includes thin walls, sharp internal corners, deep slots, or long unsupported features, you should assume higher fracture risk unless the supplier demonstrates a proven machining strategy for that feature class.

Strategy > Machine Brand (Toolpath & Parameters Matter)

In Jade Processing, CNC success depends heavily on how the supplier plans toolpaths and cutting parameters. Smooth toolpaths that avoid sudden direction changes reduce shock loading, which reduces crack initiation risk. Multi-step machining that gradually approaches final geometry is safer than deep single-pass cuts, even if it is slower.

Tool selection matters too, because different diamond tools and burr geometries create different force vectors and heat characteristics. Coolant, dust control, and vibration management are not “factory aesthetics”—they directly affect micro-chipping and surface integrity. A supplier who talks about process controls is usually safer than a supplier who only shows machine photos.

If you want CNC precision without CNC surprises, the best buying practice is to request: (1) the critical dimensions list, (2) the planned inspection points, and (3) a clear statement of defect policy if hidden cracks appear. Those three items do more for your outcome than arguing about whether CNC is “better” than hand carving.

How Hand Carving Achieves Control — And Its Precision Ceiling

Continuous Feedback Loop: “Feel” as Real-Time Material Sensing

Hand carving remains powerful in jade because it offers continuous feedback. A skilled carver can adjust pressure, direction, and tool engagement in real time based on sound, vibration, and resistance. In practice, this is a form of material sensing that helps the artisan avoid pushing force into a risky direction.

This adaptability is valuable when the stone has uneven density, mixed structure, or localized brittleness. It is also valuable when the design intent is aesthetic rather than geometric, because a human can decide how to “use” the stone’s natural features to make the final piece look more premium. For brands selling artistic uniqueness, hand carving is often part of the product story and part of the perceived value.

From a B2B standpoint, hand carving is less about romantic craftsmanship and more about risk management in natural material. When the stone behaves unpredictably, the ability to adapt can protect yield and preserve the visual outcome.

Why Hand Carving Often Reduces Catastrophic Breakage

Because a human can reduce force the moment the stone signals instability, hand carving can reduce catastrophic breakage in certain scenarios. This does not mean hand carving is “safer” overall, but it can be safer for designs that require delicate transitions, thin edges, or artistic contouring in stones that vary widely.

Hand carving can also be better at hiding or working around minor natural defects while maintaining an acceptable appearance. In commercial terms, this can improve usable yield by converting borderline material into saleable product—especially for one-off or small-batch orders. For small studios or boutique brands, this flexibility can be worth more than strict geometric repeatability.

That said, this advantage depends on actual skill, not the label “handmade.” For sourcing, the key is whether the supplier can show consistent hand-carved outputs across different artisans and different material lots, and whether they have an internal standard for what “acceptable” means.

Limits: Absolute Tolerance and Batch Consistency

Hand carving has a precision ceiling that shows up when you require tight dimensional tolerance, consistent symmetry across pairs, or exact match to CAD geometry. Even highly skilled artisans will produce slight differences, especially across batches, because human interpretation and micro-adjustments vary. This does not automatically mean the output is worse; it means you need to define which dimensions truly matter.

For buyers, the failure mode is common: you approve a beautiful sample, then production pieces vary just enough to create customer complaints or setting-fit issues. This happens when you treat an aesthetic approval as a dimensional approval. If you need consistent fit—like holes for jewelry findings, matched pairs, or tight assembly—you should either choose CNC, or you should choose a hybrid workflow where CNC locks geometry and hand finishing preserves aesthetics.

The most reliable approach is to classify your requirements: what must match, what may vary, and what must be visually consistent. Once those are defined, a hand-carving supplier can quote honestly and execute without guesswork.

Material Reality: Why Jade Behaves Unlike Metal (Orientation, Structure, Hidden Fractures)

Grain/Structure Direction Changes How Force Travels

In Jade Processing, the biggest mistake buyers make is assuming jade behaves like a standardized engineering material. Metal stock has predictable grain and yield behavior; jade does not. The internal structure can vary not only between lots, but between two pieces cut from the same boulder. That variability changes how cutting forces propagate, which is why two “identical” blanks can produce very different results under the same process.

This is also why process choice is not just about “precision” in the abstract. It is about whether the process can maintain precision while respecting the stone’s internal structure. In practice, grain direction and structure influence where micro-chipping starts, how edges hold, and whether thin features survive. When a supplier tells you they evaluate orientation before cutting, that is not a ceremony—it is an attempt to control the probability of failure.

Hidden Fractures Often Reveal Only During Processing

A major operational reality in jade is that many fractures are not visible on the surface. A piece can look clean and still contain internal weaknesses that only reveal themselves once stress is introduced by cutting, grinding, or drilling. That is why breakage can appear “sudden,” especially in later stages when the part is thinner and more fragile.

For sourcing, you should treat this as a risk category, not a supplier “mistake,” unless the supplier is skipping evaluation or ignoring warnings. The best suppliers do two things: they communicate the defect risk upfront, and they design a workflow that can detect problems early—before the most expensive labor stages like detail finishing and high-polish.

If you want fewer disputes, add a clause to your acceptance logic: define how “latent defects” are handled, and define whether remake is expected, discounted, or substituted with a visually equivalent stone. This sounds strict, but it actually reduces conflict because both sides can price the risk instead of arguing about blame.

Jadeite vs Nephrite: Structural Differences Affect Processing Behavior

Even inside “jade,” different material categories behave differently. Commercially, buyers often lump everything under one word, but jadeite and nephrite can respond differently to tool engagement and stress. That difference shows up in brittleness, edge holding, and crack propagation behavior, which ultimately impacts achievable precision and yield.

In practical terms, a design that is stable in one type may be higher-risk in another, especially if it relies on thin geometry or sharp transitions. That is why a professional RFQ should state not only the design file and size, but also the material type and any constraints around color, translucency, and structural grade. When the supplier can match process to material behavior, you get more reliable outcomes and fewer “surprises.”

Precision Comparison Matrix — What Each Method Can Reliably Hold

Feature Categories (Your Design Determines the Best Process)

The most useful way to compare CNC vs hand-carved precision is not to debate craftsmanship. It is to sort your design into feature categories. Some features are geometry-driven—like holes, slots, mirrored symmetry, repeated patterns, and consistent thickness. Other features are expression-driven—like organic contour, artistic transitions, and “flow” that adapts to the stone’s natural character.

When your design is geometry-driven, CNC typically performs better because it can execute repeatable toolpaths and preserve feature relationships across batches. When your design is expression-driven, hand carving can perform better because it can react to material variability and steer around risk while preserving aesthetic intent. Most commercial products contain both feature types, which is why hybrid manufacturing often wins in the real world.

Repeatability vs Adaptability Trade-off

CNC generally offers higher repeatability, especially across a production run where you need consistency between units. That consistency is valuable when your customers expect standardized SKUs, matched pairs, or compatibility with accessories and settings. CNC also makes it easier to enforce acceptance criteria because you can measure the same dimensions the same way every time.

Hand carving generally offers higher adaptability. It can “save” parts that would otherwise crack under aggressive machining, and it can preserve visual quality when the material’s internal behavior is inconsistent. The trade-off is that batch-to-batch variation becomes harder to control, especially when multiple artisans are involved.

For buyers, the decision is often about what you want to optimize: tight geometry or material-resilient finishing. If your product will be judged on fit and symmetry, prioritize CNC control. If it will be judged on artistic detail and stone character, prioritize hand carving—or specify a hybrid process so you get both.

“Acceptable Variation Range” for Natural Stone Production

Because jade is a natural material, you should define “precision” as an acceptable variation range rather than a fantasy of perfect sameness. This is especially important for visual attributes, but it also applies to geometry in some categories. For example, a hole diameter might be tight-tolerance because it affects assembly, while relief depth might be range-tolerance because it is aesthetic.

A professional way to set this up is to separate requirements into three bands:

- Must-Hit (Critical-to-Fit): Dimensions that affect assembly, matched pairs, or customer complaints.

- Should-Hit (Brand Consistency): Dimensions that affect perceived consistency but do not break functionality.

- May-Vary (Natural Character): Areas where variation is acceptable or even desirable.

When you define these bands early, your supplier can choose the right process strategy and price it honestly. You also reduce the risk of “silent substitutions,” where a supplier changes finishing or detail level to protect yield without telling you. Clear ranges protect both parties.

Best of Both Worlds — Hybrid Jade Processing (CNC Roughing + Hand Finishing)

Hybrid Definition: Automate What’s Predictable, Human-Handle What Isn’t

Hybrid Jade Processing is often the most commercially reliable model: use CNC for what it does best—repeatable geometry—and use hand work for what humans do best—adaptive finishing and aesthetic refinement. Hybrid is not a compromise; it is a deliberate risk-control strategy that targets consistent outcomes in a variable material.

A typical hybrid logic is: lock down key dimensions by CNC roughing and semi-finishing, then let artisans refine contours, transitions, and micro-details in a way that respects the stone’s behavior. This approach can protect yield while still delivering a premium look, which is why it is common in supplier workflows that serve brands.

Typical Hybrid Workflow + “Risk Checkpoints”

A robust hybrid workflow usually includes checkpoints that catch problems early:

- Pre-evaluation: grade the rough, check orientation, identify risk zones.

- CNC roughing: conservative material removal with low shock loading.

- Mid-process inspection: verify key dimensions, check for crack emergence.

- Hand refinement: detail carving, edge tuning, aesthetic corrections.

- Polishing & final QC: surface consistency, final measurement, packing standard.

From a buyer perspective, the key is not the exact sequence, but whether the supplier can show you where they check risk and how they prevent late-stage catastrophic scrap. Hybrid works best when the supplier treats inspection as part of production, not as a final gate at the end.

When Hybrid Is the Default Choice

Hybrid is especially strong when you have designs that combine functional geometry (holes, fitment, symmetry) with visual storytelling (organic lines, relief transitions, natural stone aesthetics). It is also strong when your order volume is enough to justify CNC setup, but your material lot still has variation that requires human judgment.

If you are building a product line rather than a one-off artwork, hybrid often produces the most stable mix of: predictable lead time, manageable defect risk, consistent branding geometry, and premium perceived value. That stability is what procurement and product teams ultimately need.

How Buyers Should Specify Precision (So Quotes & QC Don’t Collapse Later)

Spec Language That Works (What to Put in an RFQ / PO)

If you want fewer delays and fewer arguments, your RFQ should describe precision in measurable terms, not in adjectives like “high quality” or “fine detail.” In Jade Processing, the most common failure is that the buyer approves a sample visually, but the production acceptance criteria were never written down. When expectations are not measurable, the supplier is forced to guess what you will accept, and that guess changes from person to person.

A practical structure is to list Critical-to-Fit features first, because these are the dimensions that can break assembly or trigger returns. Examples include: hole diameter and position, thickness that must fit a setting, mirrored symmetry for pairs, groove width for inlay, and any mating surfaces. Then list Brand Consistency features second, such as relief depth range, edge radius style, and signature line geometry that should look consistent across SKUs.

For each Critical-to-Fit feature, specify three items: (1) nominal value, (2) tolerance band, (3) measurement method. Even if your tolerance is not ultra-tight, writing it down forces alignment. For aesthetic features, use range language and reference photos, because natural stone variation makes single-number targets unrealistic and invites disputes.(Jade properties & definitions)

Inspection Methods by Risk (Don’t Over-Promise Certainty)

Good suppliers don’t just promise results; they define how results are verified. Your RFQ should request a simple inspection plan that matches your risk profile. For geometry-driven designs, ask for a measurement report on key dimensions across a batch (even a small batch). For surface-driven designs, ask for standardized photo angles and lighting conditions so visual inspection is comparable between sample and production.

Because jade can contain hidden fractures, it is also important to separate process defects from material defects. A process defect is something like wrong dimensions, incorrect pattern execution, or inconsistent polish standard. A material defect is a crack or weakness that was not visible and only revealed during machining. A professional supplier can’t eliminate material defects, but they can reduce the chance of late discovery by adding checkpoints and communicating risk earlier.

If your brand is sensitive to delivery stability, request that the supplier defines: what they do when latent defects appear mid-process, whether substitutions are allowed, and whether rework or remake is included in the quote. This prevents “silent re-optimization” where suppliers adjust finishing levels to protect yield without informing you.

Preventing Disputes: Align Expectations Before Production

Disputes usually happen when three things are missing: a feature priority list, a defect policy, and a shared visual standard. A buyer may say “this batch is inconsistent,” while the supplier says “it’s natural stone,” and both may be correct. The only way out is to define, upfront, what variation is acceptable and what variation is not.(GIA)

A clean way to do this is to attach a one-page Acceptance Criteria Sheet to the PO. It includes: critical dimensions and tolerances, a small set of reference photos, the minimum polish/finish standard, and a note describing how latent defects are handled. This is not “extra paperwork.” It is a tool that allows both sides to price risk properly and execute without guessing.

If you want to speed up quoting and reduce back-and-forth, include your use case in the RFQ: Is this for jewelry settings, for display objects, for collector-grade art pieces, or for standardized consumer SKUs? The more clearly the supplier understands how the product will be judged, the more accurately they can propose CNC, hand carving, or hybrid—and the fewer surprises you’ll face after sampling.

Cost, Yield, and Lead Time — Precision Has a Price (Because Risk Has a Cost)

CNC Is Efficient Only When Yield Is Predictable

CNC can be cost-effective when your design is stable, your material quality is consistent, and your yield is predictable. In that scenario, the supplier spreads setup cost across volume, repeats the same toolpaths, and controls labor time per unit. This is why CNC often wins for standardized SKUs and repeat orders with consistent material grading.

But when yield becomes unpredictable, CNC efficiency can collapse. If breakage happens late in the process, you lose not only material but also accumulated machining time and downstream finishing cost. The more your design pushes thin features, sharp transitions, or deep cuts, the more important it becomes to plan conservative machining stages and insert early inspection checkpoints.

For buyers, the key point is that CNC pricing is not purely about machine time. It is also about how the supplier models risk. A very low quote can be a signal that the supplier is assuming a yield that is not realistic for the design or material grade.

Yield Is a Probability Distribution, Not a Promise

In natural stone manufacturing, yield should be treated as a probability distribution: a certain percentage will be perfect, a certain percentage will be acceptable with minor variation, and a certain percentage will fail. This is not failure of management; it is the economics of variable material under stress. Precision requirements tighten the acceptance window, which effectively pushes more parts into rework or scrap categories.

That means “precision” is not free. If you require tighter tolerance and higher consistency, your supplier must either use higher-grade material, run more conservative processes, add inspection steps, or accept higher scrap buffers. All of those cost money or time. This is why two quotes can differ massively even when both suppliers are technically capable: they are pricing different assumptions about yield and risk.

A healthy buyer mindset is to ask: what assumptions are baked into the quote? What defect rate is assumed? Is rework included? Is replacement included? Asking those questions turns pricing from a gamble into a controlled decision.

Why “Low Quotes” Often Hide Risk Deferral

When suppliers quote too low, the risk doesn’t disappear—it is deferred. It can show up as: extended lead times, last-minute design change pressure, quality downgrades, or inconsistent finishing. Sometimes the supplier will “simplify” micro-details to protect yield, or they may substitute slightly different stones to keep production moving. If your acceptance criteria are not written, these changes can happen without a formal discussion.

This is why procurement should evaluate a supplier’s quote as a process proposal, not just a unit price. A credible quote explains process selection (CNC/hand/hybrid), identifies risky features, suggests risk mitigations, and states inspection checkpoints. Even if the unit price is higher, the total cost of ownership can be lower if it prevents rework, delays, and disputes.

If you want reliable delivery, treat transparency as a capability. The supplier who can explain risk clearly is often the supplier who can control it better.

Buyer Checklist (RFQ-Ready): 12 Questions That Instantly Reveal Capability

Design & Tolerance Questions

- Which features are Critical-to-Fit, and what tolerance can you hold on them?

- For paired items, how do you control symmetry matching across pieces?

- What minimum wall thickness and edge style do you recommend for this design?

- Which details are high-risk for breakage, and what design changes would reduce risk?

Material Risk Questions

- How do you grade and select rough material before production?

- How do you handle latent defects discovered mid-process (replace, discount, substitute)?

- What material types are assumed (jadeite/nephrite), and how does that change your process plan?

- Can you propose a material grade that balances appearance, yield, and cost for this SKU?

Process & QC Questions

- What is your recommended workflow: CNC, hand carving, or hybrid—and why?

- Where are your inspection checkpoints, and what is measured at each step?

- What will you provide as evidence: measurement report, standardized photos, batch QC summary?

- If a unit fails final inspection, what is your remake or rework policy and timeline?

FAQ

Can CNC jade carving be “as good as” hand carving?

CNC can match or exceed hand carving on repeatable geometry and dimensional control, especially for standardized products. It does not automatically guarantee better artistic outcomes, because “good” in jade often includes how the design adapts to natural variation.

What should I ask a supplier to prove precision?

Ask for a simple batch measurement report for key dimensions, and ask how they define acceptance criteria. If they can’t explain inspection checkpoints and defect handling, “precision” is usually a marketing claim rather than a controlled process.

Why do some CNC jobs crack late in production?

Because jade can have internal weaknesses that aren’t visible, and machining applies stress consistently. Late-stage geometry can be thinner and more fragile, so defects reveal when the part has the least structural margin.

-900x375.webp)