Introduction

Luxury jade decor can look stunning in a hotel lobby, but commercial reality is brutal. High foot traffic, constant dust, luggage impact, repeated wiping, and aggressive disinfectants can dull gloss, show micro-scratches, and leave staining—often faster than design teams expect.

This guide is written for hotel owners, procurement teams, interior designers, and facility managers who need a durable, maintainable jade solution. You’ll learn what actually causes wear, how factory-grade protection strategies work (and what they cannot promise), how to validate durability before full installation, and how to write a maintenance SOP that keeps the surface looking premium over time.

Table of Contents

Executive Summary — What Actually Extends Jade Service Life in High-Traffic Spaces

The three most common failure modes

In commercial spaces, jade decor typically “fails” in one of three ways: micro-scratching that turns into haze, chemical dulling or etching, and staining/contamination trapped in texture or joints. None of these failures require dramatic damage to look bad; a subtle gloss drop under lobby lighting can make a premium feature look tired.

Your job is not to chase “scratch-proof jade.” Your job is to reduce probability of visible wear and make inevitable wear easier to manage through design, finishing, protective strategy, and cleaning rules.

What protective layers can and cannot do

A protective coating for jade can improve cleanability and reduce risk of staining and chemical marks. However, it cannot rewrite material reality, and it should never be marketed or specified as a permanent guarantee of perfection.

The same internal document set used for buyer education warns against absolute language and recommends stating what was tested, what was detected, and what remains uncertain rather than implying certainty.

The practical framework

For hotel and lobby installations, durability comes from four combined decisions:

- Material & structure choice (jade type, internal variability, orientation risk)

- Finish selection (gloss vs satin/matte; texture depth; edge geometry)

- Protection strategy (penetrating protection vs thin-film topcoat vs hybrid approach)

- Maintenance SOP (cleaner rules, tools, frequency, spill response, inspection)

If you only do #3 and ignore #2 and #4, the project is likely to disappoint, no matter how “factory-grade” the coating sounds.

Why Jade Wears in Commercial Interiors

Abrasion and micro-scratching: dust is the invisible sandpaper

Most lobby scratching is not caused by “someone scratching the stone.” It’s caused by dust and grit dragged across the surface by shoes, luggage wheels, cleaning tools, and microfiber cloths that aren’t as clean as people assume.

Micro-scratches accumulate until they scatter light. Under strong lobby lighting, the surface can look hazy even if guests can’t feel any damage by hand.

Chemical exposure: the wrong cleaner can do more damage than traffic

Housekeeping teams often use stronger chemicals to move faster. Unfortunately, harsh chemicals can accelerate gloss loss, leave streaks, or create a permanently dull patch that looks like a “bad polish job.”(neutral pH cleaner)

This is why commercial durability is not only a manufacturing issue. It is equally a facility operations issue, and it must be managed with a written SOP that facilities teams can follow without guessing.

Impact points: corners, edges, and high-touch zones

Most visible damage shows up at edges and corners, or where people touch surfaces repeatedly. For carved or layered installations, dust and oils collect in recesses and make cleaning more aggressive—raising the wear rate.

Environmental stress: UV, thermal cycling, and humidity

Hotel lobbies often have large windows and temperature gradients. UV can accelerate yellowing of some surface layers, while thermal cycling can stress bonded assemblies or seams.

This is why coating selection must consider service conditions, not just how good the sample looks in a showroom.

Finish First — The Finish Choice Often Matters More Than the Coating

High-gloss vs satin vs matte: what changes in maintenance

High gloss shows micro-scratches sooner under downlights. Satin and matte finishes hide micro-scratches better, but they can trap dirt in texture and require more deliberate cleaning technique.

If your lobby design demands mirror-like gloss, you should treat the surface plan as a lifecycle plan. That means planning for inspection, gentle periodic refresh, and realistic expectations about visible wear over time.

Texture and carving depth: dirt accumulation is a design variable

Deep texture, sharp valleys, and dense patterns look premium—but they create cleaning complexity. The more complex the surface geometry, the more likely housekeeping will over-clean with pressure, abrasive pads, or harsh chemicals.

If the design needs deep carving, you should counterbalance it with better cleanability planning. That means specifying cleaning tools, training notes, and a spill response routine that doesn’t rely on scrubbing.

Edge design and mounting method reduce chipping and scuffing

Edges are where mechanical impact concentrates. Small radii and protected edges reduce the probability that a single luggage collision creates a visible defect.

In manufacturing terms, design choices directly change risk. The same knowledge base emphasizes that outcomes are probabilistic in natural stone, and professional factories manage ranges rather than promising absolutes.

Protective Coating for Jade — Factory-Grade Options (and How to Choose)

Commercial buyers usually ask, “What’s the best protective coating for jade?” The better question is, “Which protection strategy matches our service conditions, visual requirements, and maintenance discipline?”

The internal treatment reference notes that surface treatments (waxing/oiling/transparent coatings/sealants) modify appearance without changing internal structure, and that surface-treated stones may degrade faster during wear or cleaning. It also stresses disclosure when treatment alters appearance or performance.

Below are the three most practical option families for hotel and lobby projects.

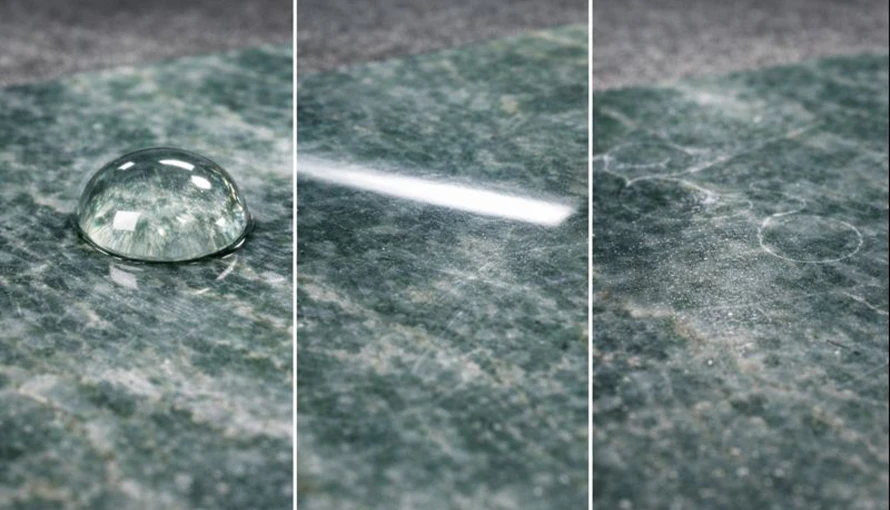

Category 1 — Penetrating protection (impregnation-style stain protection)

Penetrating protection aims to reduce staining by limiting how liquids and contaminants interact with near-surface porosity or micro-texture. In many projects, this is chosen when stain resistance and easier wipe-down are the top priorities.

This strategy is typically not the best answer if your biggest fear is abrasive scratching. It helps with maintenance and reduces risk of permanent staining, but it won’t magically stop micro-scratches from grit.

Best for: beverage exposure, public areas with frequent wipe-down, surfaces where appearance change must be minimal.

Trade-off to manage: stain reduction ≠ scratch elimination.

Category 2 — Thin-film topcoats (clear protective layers for cleanability)

A thin-film topcoat can improve surface cleanability and short-term resistance to light scuffing. In real commercial conditions, topcoats are best understood as a service layer—they may need refresh or recoat depending on traffic and cleaning intensity.

This matters because the same document set warns that surface-only enhancement can appear “too perfect” at first and then degrade, which can create delayed performance disputes if expectations are not set properly.

Best for: high-touch surfaces, feature walls near check-in counters, areas where cleaning speed is critical.

Trade-off to manage: a service layer must be specified, disclosed, and maintained.

Category 3 — Hybrid systems (base protection + topcoat strategy)

Hybrid strategies are useful when you need a balance between stain resistance and improved cleanability. They also create more tuning knobs—preparation, application thickness, curing discipline, and inspection become more important.

Hybrid thinking is consistent with how professional workshops manage natural stone risk. The same manufacturing reference explains that hybrid workflows (mixing CNC and manual intervention) are often used because they automate what’s predictable and use judgment where uncertainty is highest. That mindset applies to finishing and protection too: standardize what you can, and manage the variability you can’t.

Best for: flagship lobbies, premium retail, projects with strict appearance expectations and planned maintenance.

Trade-off to manage: more steps mean more QC and documentation.

Visual impact checklist: what buyers should evaluate on samples

Before approving a protective layer, evaluate these items under the same lighting the lobby will use:

- Gloss change (higher gloss can look great but show wear sooner)

- Color shift (some layers create a “wet look” effect)

- Haze risk (especially on high-polish surfaces)

- Feel and fingerprinting (high-touch zones reveal issues fast)

- Consistency in recesses (carved areas expose uneven application)

If a treatment produces an unusually “wet-look” gloss inconsistent with the material, the treatment guidance flags that as a risk indicator that may not age well.

What “Factory-Grade” Really Means: Process Controls That Decide Whether Protection Lasts

Many coating failures are not caused by the coating “type.” They are caused by surface preparation shortcuts, inconsistent thickness, and rushed curing.

Surface preparation: cleanliness and micro-behavior

Protection layers depend on how the surface is prepared. Oils, residue from polishing compounds, dust, and moisture can reduce adhesion and create future haze or peeling.

The bigger idea is consistent across manufacturing: process consistency is controllable, but material variability still introduces randomness. Good factories manage both with checkpoints.

Application consistency: thickness and coverage discipline

If a topcoat is uneven, you may see “patchy” behavior after cleaning—some areas dull faster, some hold gloss longer. That difference becomes very visible under lobby spotlights.

For textured designs, uniform coverage is harder, which is why deep carving should trigger a more conservative protection plan and stricter QC.

Curing and post-cure inspection: the invisible step that saves projects

Curing discipline affects durability and chemical resistance. Post-cure inspection should include visual reflection checks, defect identification, and documentation for future maintenance reference.

Quality control checkpoints: state what you did, not what you wish

When communicating durability, the internal testing guidance recommends describing the test logic clearly and avoiding absolute claims. In other words, say what was tested and what remains untested rather than implying “guaranteed for everything.”

That same logic reduces disputes in hotel projects. If procurement receives a realistic test matrix and a clear maintenance SOP, expectations become enforceable.

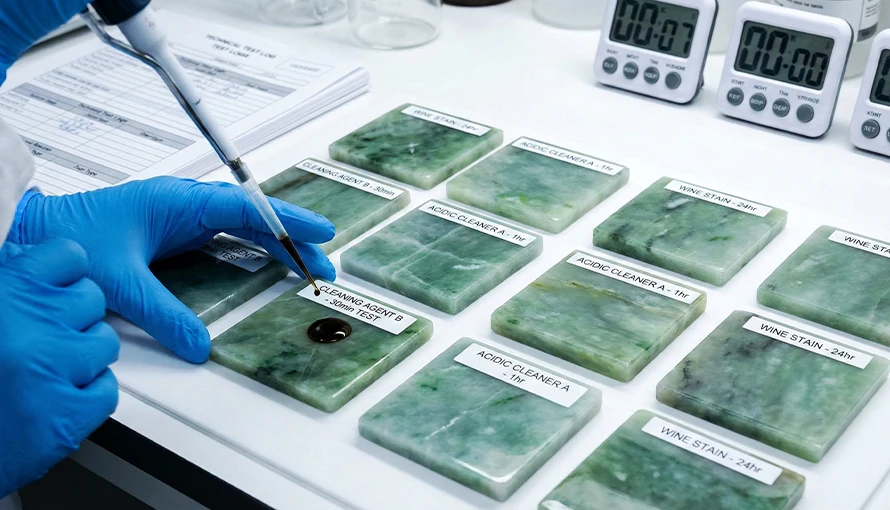

Testing That Matters for Hotels: Validate Durability Before Full Installation

A luxury lobby is not the place to “find out later.” The smartest path is to validate with a sample panel and a pilot area, using tests aligned to actual service conditions.

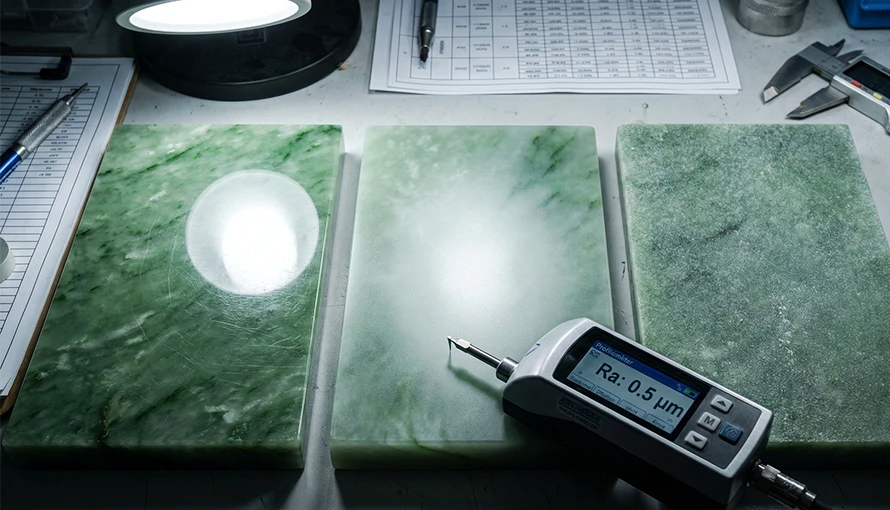

Abrasion and scratch screening: use relative comparison, not “scratch-proof” language

Scratch and abrasion tests are most useful when comparing multiple finish/protection options. The goal is to learn which option has better resistance under a defined condition, not to pretend the result predicts every possible event.

This aligns with the internal rule: choose tests based on what you need to know, and communicate results with disclosure rather than certainty.

Chemical spot testing: match housekeeping reality

Make a list of cleaners and disinfectants that housekeeping actually uses. Test those products on your sample panel with controlled dwell times and wiping methods, then inspect for gloss change, haze, or tackiness.

If your hotel will switch cleaning products seasonally or by vendor, include that operational risk in your planning. A protection system is only as good as the cleaning discipline it survives.

Stain testing: simulate lobby exposure

Coffee, wine, oils, cosmetics, and hand lotion represent real exposure in lobbies and public areas. Stain testing is essential for reception desks, feature walls near seating, and any surface near food service.

Gloss retention and haze observation: test under the same lighting

Gloss change can be subtle in a workshop but obvious in a lobby. Always evaluate samples under comparable lighting angles, because that is where micro-scratches and haze become visible.

Pilot area strategy: approve a small zone first

Instead of installing a full lobby feature at once, install a pilot zone. Operate it for a defined period with real cleaning routines, then evaluate.

This approach reflects a broader manufacturing truth: in natural materials, you can standardize process but not the stone, so professional planning uses ranges, checkpoints, and probabilistic thinking.

Maintenance SOP for Jade Decor in Commercial Spaces

A maintenance SOP is not a “nice to have.” It is part of the product. Without it, the project’s durability becomes random, and random outcomes become disputes.

Daily cleaning: keep it gentle and consistent

Daily cleaning should prioritize dust removal and gentle wipe-down. Use clean microfiber and avoid introducing grit that becomes a polishing compound.

If cleaners are used, they should be chosen for compatibility with the chosen finish and protection layer. The worst operational pattern is switching between multiple strong chemicals because different shifts have different habits.

Weekly and monthly routine: inspection beats scrubbing

Weekly routines should include inspection for early haze, edge scuffs, or recess buildup. Monthly routines can include a gentle refresh method approved for the specific finish strategy.

When maintenance is defined as inspection plus controlled response, teams are less likely to “scrub until it looks clean,” which is the fastest route to accelerated wear.

What to avoid: the usual causes of sudden failure

Avoid abrasive pads, gritty powders, and unknown “stone cleaners” that may contain aggressive components. Avoid high-pressure scrubbing on carved recesses, because it concentrates wear at edges.

The surface-treatment guidance explicitly notes that surface enhancements may degrade with wear or cleaning, which makes improper cleaning one of the highest leverage failure causes.

Spill and scuff response: speed matters more than force

For spills, blot and lift rather than rub aggressively. For scuffs, use the lightest effective method, escalating slowly to avoid turning a removable mark into a permanent haze patch.

Planned refresh and recoat: if you choose a service layer, own the lifecycle

If the project uses a topcoat strategy, treat it like a maintainable system with a refresh interval. Procurement should plan for what happens when the service layer shows wear: who does the refresh, how it is documented, and what “acceptable wear” looks like under lobby lighting.

Spec + RFQ Checklist: How Procurement Gets What Design Expects

Commercial jade projects fail in writing before they fail on the wall. Your RFQ should capture finish strategy, protection approach, validation requirements, and maintenance obligations.

What to specify in writing

- Material definition: jade type, expected natural variability range, any special aesthetic constraints

- Finish definition: gloss level target, texture depth, edge geometry standards

- Protection strategy: category (penetrating / topcoat / hybrid), visual impact allowance, service-layer expectations

- Testing plan: sample panel tests, chemical list, abrasion/scratch comparison method, evaluation lighting conditions

- Maintenance SOP: approved cleaners/tools, do-not-use list, inspection frequency, spill protocol

This approach aligns with the manufacturing guidance that “same process ≠ same outcome” in natural stone. If you want tighter consistency, you must define acceptable ranges and the cost/risk implications.

Acceptance criteria at delivery and after installation

Define acceptance criteria at two stages:

- Pre-installation acceptance: sample matching, visible defect thresholds, finish uniformity under defined lighting

- Post-installation acceptance: performance after cleaning trial, seam visibility rules, touch-up policy

This reduces disagreements caused by subjective “it looks different now” complaints after the space has been cleaned for the first time.

Repairability and spares: plan for operational reality

In hotel operations, accidents happen. Plan spares for high-risk areas and define whether repairs are expected to be invisible or simply acceptable within an agreed range.

The broader manufacturing guidance around risk management emphasizes mitigation before, during, and after processing. Your installation and maintenance plan is part of that mitigation mindset.

Practical Implementation Plan (A Buyer-Friendly Checklist)

Step 1: Define service conditions

List traffic level, cleaning frequency, chemicals used, and exposure risks. Treat this like a specification input, not an afterthought.

Step 2: Choose finish strategy first

Decide gloss/matte, texture depth, and edge geometry based on both aesthetics and maintenance reality. If design demands deep carving or mirror gloss, expect higher maintenance sensitivity.

Step 3: Select protection category and approve by sample panel

Run a sample panel process: visual approval + chemical spot tests + abrasion/scratch comparison under the correct lighting. Communicate results in scope-based language to avoid future disputes.

Step 4: Write the maintenance SOP and include it in the contract

Make SOP compliance part of acceptance and warranty logic. A protection system cannot perform if the daily process destroys it.

Step 5: Pilot zone and scale

Install a pilot area, run real cleaning routines, inspect, and then scale installation with documented parameters. This reflects the “risk checkpoint” logic used in hybrid workflows and professional risk management.

FAQ

Is jade “scratch-proof” in hotel lobbies?

No natural stone used in high-traffic spaces is realistically scratch-proof under all real-world conditions. The practical goal is to reduce the probability of visible scratches and make maintenance predictable.

This matches the internal guidance to avoid absolute language and communicate durability as controlled scope rather than guarantees.

What’s the best protective coating for jade home decor?

The “best” option depends on service conditions, visual requirements, and how disciplined cleaning will be. In practice, penetrating protection is often chosen for stain control, thin-film topcoats for cleanability and surface resilience, and hybrid strategies for premium flagship areas.

Can coatings change the color or gloss of jade?

Yes, surface treatments can change gloss perception and color depth, and some can create a “wet look.” The treatment reference lists common surface enhancements (waxing/oiling/transparent coatings/sealants) and warns that surface enhancement can be superficial and degrade with wear or cleaning.

What cleaners are safe for jade decor?

Cleaners should be chosen based on compatibility with the specific finish and protection strategy, and they should be standardized across shifts. The safest operational approach is defining an approved cleaner list and a do-not-use list in the SOP.

How often should protection be refreshed in high-traffic areas?

It depends on traffic, cleaning method, and whether the protection layer is a service topcoat. This is why pilot zones and scheduled inspections are practical: they create an evidence-based refresh interval instead of guesswork.

-900x375.webp)