Introduction

When buyers compare jadeite and nephrite, the conversation often starts with “which one is better,” but the purchase risk is usually about yield, consistency, and cost predictability. In real manufacturing, the material name alone doesn’t protect your PO from scrap spikes, late cracks, or quote drift—your design + process assumptions do. This means, you can turn a “jade choice” into a controllable sourcing decision instead of a cost surprise.

If you’re searching “jadeite vs nephrite” as a product manager, studio owner, or procurement lead, you’re likely trying to answer: Will this material hit my target look without blowing up lead time and QC? This article translates gem science into buyer-operable steps, ROI logic, and compliance guardrails so you can write a better RFQ and get stable production outcomes. This means, you can reduce back-and-forth with suppliers and get quotes that stay stable from sample to mass production.

Table of Contents

The Buyer’s Decision in One Page

Most buyers don’t need a mineralogy lecture—they need a decision that holds under scale. Use this as your “one-page” filter before you even send CAD files. This means, you can choose faster and avoid paying for the wrong kind of “premium.”

.webp)

Choose Jadeite when the product value depends on premium optics

Jadeite is widely associated with higher-end jewelry and can show a “glassier” look when quality and translucency are strong, which is one reason it often commands higher market value. That visual premium can justify more conservative machining, slower finishing, and stricter selection of rough, but only if your customer actually pays for that difference. This means, you can align material choice with pricing power instead of absorbing premium costs that your market won’t repay.

Choose Nephrite when production stability and impact resistance matter most

Nephrite is commonly described as tougher (more resistant to breakage) due to its fibrous microstructure, while jadeite is generally harder but can be less forgiving in edge chipping under certain machining stresses. Classic materials research and gem references distinguish hardness from toughness, and nephrite’s toughness is often the stability advantage in complex carving or thin sections. This means, you can reduce catastrophic failure risk on thin or intricate designs and improve batch yield predictability.

Your real decision is “risk profile,” not “which jade is better”

If your product has risky geometry (thin bridges, sharp internal corners, deep engraving), “jadeite vs nephrite” becomes a question of how much yield volatility you can tolerate. A material that looks better on a single hero sample may cost more in production because it forces slower removal, more tool changes, and more rejects on the tail end of finishing. This means, you can select the material that protects your margin, not just your mood board.

A practical matrix you can paste into your RFQ

| Buyer Priority | Likely Better Fit | Why it matters in manufacturing |

|---|---|---|

| Premium optics and perceived luxury | Jadeite | More buyers accept higher MSRP; allows higher finishing budgets |

| Stable yield on complex shapes | Nephrite | Toughness reduces breakage/chip sensitivity |

| Tight delivery windows | Often Nephrite | Lower risk → fewer reworks and restarts |

| Highly consistent repeat batches | Either (process-led) | Consistency depends on sorting, process discipline, and acceptance criteria |

This is not a guarantee—your supplier’s process maturity matters as much as material selection. But using a matrix like this forces the quote to reflect risk allocation rather than vague statements like “jadeite is difficult.” This means, you can make the supplier’s assumptions visible before you place a deposit.

Material Reality Buyers Can Use — Hardness Is Only Half the Story

Buyers often hear “jadeite is harder” and assume it must be “better,” but hardness is only one axis of manufacturability. In production, the pain usually comes from the gap between scratch resistance (hardness) and break resistance (toughness). This means, you can stop overpaying for a single property and start buying for real-world production outcomes.

Mohs hardness explains scratch resistance and some finishing cost

Authoritative gem references commonly list jadeite around Mohs 6.5–7 and nephrite around Mohs 6–6.5. (gia.edu) Because Mohs is ordinal (not linear), “0.5 higher” can still change how the surface responds to abrasive finishing and how quickly tools lose cutting efficiency. This means, you can anticipate why some jadeite SKUs need longer finishing time and budget accordingly.

Toughness explains yield, chipping, and late-stage failures

The famous buyer trap is assuming “harder = less likely to break,” when toughness is what governs resistance to cracking and fracturing under stress. A classic mineralogical study specifically notes that jadeite is harder, but nephrite is tougher and stronger, and it links this to fracture behavior and microstructure. This means, you can choose nephrite for designs where breakage risk costs more than minor differences in scratch resistance.

Microstructure is what your supplier is fighting, even if they don’t say it

Jadeite is typically described as an interlocking granular aggregate, while nephrite is often characterized by a fibrous interlocking structure. Those structural differences influence how cracks initiate and propagate when tools introduce vibration, localized stress, or thermal effects. This means, you can understand why two “jades” with similar hardness can behave very differently on thin edges or sharp corners.

The “so what” for buyers: hardness affects tools, toughness affects disputes

Hardness tends to show up as higher tool consumption and more time to maintain surface quality, while toughness tends to show up as fewer catastrophic breaks and more stable yield. When a supplier says “tool wear” or “crack risk,” they are often describing these properties indirectly, and your RFQ should force them to quantify the implications. This means, you can convert vague factory language into measurable quote terms and QC expectations.

What Manufacturing Outcomes Buyers Actually Feel

From a buyer perspective, “processing difficulty” only matters because it changes unit cost, lead time, and defect rate. This chapter connects material behavior to the three outcomes that make or break your margin. This means, you can predict the business impact of material choice instead of discovering it during mass production.

Tool wear is a cost multiplier, not a minor shop detail

Hard, brittle materials often remove via micro-chipping and abrasive interactions, which naturally increases wear and dulling in abrasive tools. Research on machining hard/brittle solids discusses damage mechanisms and wear behaviors that align with why conservative processes are used to avoid sub-surface damage. (PMC) This means, you can treat “tool wear” as a first-class cost driver in your quote, not a post-hoc excuse.

When tools dull, the supplier must either slow down (protecting surface quality) or push through (raising defect risk), and both outcomes cost you. In buyer terms: dull tools produce more edge chipping and inconsistent finish, which shows up as rework, remakes, or stricter sorting that reduces deliverable quantity. This means, you can ask for a tool-change policy and reduce finish variance across the batch.

Cycle time expands because “safe removal” is slower than “fast removal”

For hard/brittle materials, stable processing often requires smaller step-downs, more passes, and more conservative parameters to reduce stress concentration and cracking risk. Vibrational-assisted methods like ultrasonic machining are specifically used on hard/brittle materials because removal mechanisms differ from conventional cutting, reinforcing why “just run it faster” is often unsafe. (wikipedia) This means, you can plan lead time based on risk tier and avoid launch delays caused by hidden rework loops.

Yield is a probability curve, and your design decides the tail risk

Natural stone variability means yield is not a single number; it behaves like a distribution where most pieces succeed but a percentage fail at late stages. Late-stage failure is especially expensive because the part has already absorbed most of the machining and finishing cost before it breaks or chips beyond acceptance. This means, you can price and schedule using a realistic risk buffer instead of assuming 100% success.

A buyer-style ROI model to quantify “cost” intent (illustrative, adjustable)

Here’s a practical way to quantify ROI without pretending there is a universal number. Assume a batch of 1,000 units with a target delivered quantity of 950 sellable pieces and compare two scenarios:

- Scenario A (less stable): 85% yield, tool+process cost $X per attempted unit

- Scenario B (more stable): 92% yield, tool+process cost $X+Δ per attempted unit

If your target is 950 sellable pieces:

- At 85% yield, you must attempt 950 / 0.85 = 1,117.65 → 1,118 units

- At 92% yield, you must attempt 950 / 0.92 = 1,032.61 → 1,033 units

That’s 85 fewer attempted units—meaning fewer tool-hours, fewer finishing hours, and less calendar time tied up. Even if Scenario B costs more per attempted unit, the total cost can still drop because you attempt fewer units, and your delivery risk improves at the same time. This means, you can justify paying for stability when the math shows it reduces total cost and protects your ship date.

To use this in your RFQ, ask suppliers to quote by delivered quantity and disclose the assumed yield range by design risk tier. This forces “cost” conversations into measurable terms instead of emotional debate about which jade is “hard.” This means, you can negotiate on transparent assumptions and reduce surprise add-ons.

CNC vs Hand Carving vs Hybrid — What This Means for PO Risk

Buyers often treat process choice as a style preference, but it’s also a risk strategy. Your process choice controls repeatability, tolerance capability, and how failures are detected or prevented. This means, you can choose a workflow that protects your delivery and brand reputation, not just your prototype aesthetics.

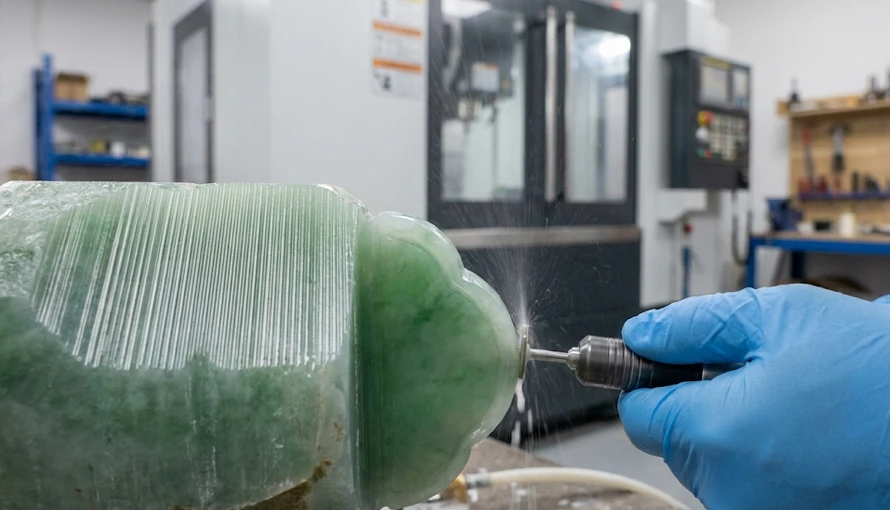

CNC helps repeatability, but it can amplify hidden material risks

CNC excels when geometry is repeatable and the material is predictable, but natural stone can contain hidden fissures or stress zones that are not visible from the surface. When a toolpath hits a weak zone at speed, failure can be abrupt and expensive, especially in later stages. This means, you can decide when CNC is appropriate and when it needs a screening + hybrid strategy to protect yield.

Hand carving adapts to variability, but consistency is harder to scale

Skilled hand carving can respond to local material feedback—adjusting pressure, direction, and sequencing to avoid propagating cracks. The trade-off is that hand processes can introduce variability in dimensions and repeatability unless you define tolerance philosophy and inspection methods clearly. This means, you can avoid mismatched expectations by specifying what must be consistent and what can remain artisanal.

Hybrid workflows are often the buyer’s best balance

A common high-control workflow is: CNC for roughing and symmetry-critical features → hand refinement for risk zones → controlled polishing. This allocates machine repeatability where it matters and human adaptability where the stone’s variability creates tail risk. This means, you can scale production while keeping catastrophic failure probability under control.

How-to steps: choose the process using a simple “risk tier” method

- Classify your design as low/medium/high risk (thin walls, sharp corners, undercuts, deep engraving, micro holes).

- Match the workflow: low risk = CNC-heavy; medium risk = CNC + hand refinement; high risk = hand-led with CNC assist.

- Require evidence: ask for a short process video of one sample showing roughing → refinement → polishing so you can validate the claimed workflow.

- Lock inspection: define how the part is measured and viewed (lighting, magnification, acceptable micro-chips).

This approach is process-agnostic and works whether you choose jadeite or nephrite. This means, you can turn “process selection” into a controllable checklist instead of supplier guesswork.

Design Rules That Protect Yield (DFM for Buyers)

Design drives risk more than most buyers realize. Two buyers can choose the same material, but the one who sends a risk-aware design will get better pricing, higher yield, and fewer disputes. This means, you can lower total cost without switching materials simply by designing for survivability.

Thin sections fail late—and that’s why they cost more than you expect

Thin walls, long bridges, and delicate prongs concentrate stress and are more likely to chip during machining or break during polishing. The economic pain is that failures often happen late, after most value-add steps are already invested in the part. This means, you can reduce late-stage scrap by setting minimum thickness rules before you prototype.

Sharp internal corners and deep engraving multiply crack initiation risk

Sharp corners behave like stress concentrators, and deep engraving increases the chance that micro-chips become visible defects. If your brand requires sharp typography or deep relief, you should expect slower processing, more tool changes, and stricter sorting standards. This means, you can budget premium features realistically and avoid arguing over predictable consequences.

Orientation is not “just rotate it” — it’s a probability game

Because jade is an aggregate material, orientation can change how forces travel through the structure. Good suppliers treat orientation as a risk mitigation choice, not a cosmetic preference, and the best orientation may differ by rough piece even within the same batch. This means, you can allow controlled orientation flexibility in your spec to improve yield while keeping appearance consistent.

How-to steps: a buyer-friendly DFM checklist you can attach to CAD

- Mark critical cosmetic faces versus hidden faces so the supplier prioritizes finishing where it pays.

- Flag no-chip zones (edges customers touch or see) so the supplier adjusts toolpath and finishing sequence.

- Define minimum wall thickness and minimum bridge width based on your market’s acceptable weight and durability.

- Avoid ultra-small holes unless necessary; if required, specify whether drilling can be replaced with slotting or post-assembly.

- Ask for a risk-grade response (low/medium/high) and require the factory to state how risk changes price and lead time.

This makes “how-to” intent actionable and reduces ambiguity. This means, you can get faster, more consistent quoting and fewer revision loops.

RFQ & Quote Guardrails — How to Get Predictable Pricing

Quote drift usually happens because the RFQ does not define material identity, treatment disclosure, defect policy, and risk-sharing. When those are vague, suppliers can underquote and then renegotiate using “tool wear” or “crack risk” as justification. This means, you can lock cost assumptions early and protect your margin.

What to specify so quotes don’t drift (copy/paste RFQ fields)

- Material identity: state explicitly “jadeite” or “nephrite,” not just “jade.”

- Treatment disclosure requirement: require written disclosure of treatments (e.g., polymer impregnation, dyeing), because treatment affects value and sometimes care. Industry and trade references document treatment categories and disclosure expectations for jadeite products. (gia.edu)

- Finish definition: define polish level and inspection method (lighting and magnification), not just “high polish.”

- Defect policy: define what counts as acceptable natural features vs unacceptable manufacturing damage (chips, edge breaks, surface pits).

- Yield assumption: request an estimated yield range by design risk tier and require quoting by delivered quantity.

These fields force the supplier to price the real work, not the dream version of the work. This means, you can reduce renegotiation risk and compare quotes on equal assumptions.

Add a simple “tool wear policy” clause for cost transparency

Ask the factory to confirm:

- tool type family (diamond abrasive class, bonding type where relevant),

- tool change triggers (time-based or quality-based), and

- whether tool cost is embedded or itemized for high-risk geometry.

Machining literature on hard/brittle materials emphasizes that removal mechanisms and tool-workpiece interactions drive wear and surface outcomes, which supports the logic of making tool policy explicit. (ScienceDirect) This means, you can turn “tool wear” from a surprise fee into a controlled quotation variable.

ROI-driven buying: pay for predictability when it reduces total cost

If a supplier proposes a hybrid workflow or stricter rough sorting that raises unit price by, say, 8–12%, your decision should be based on whether it reduces attempted units and rework enough to lower total cost. Using the yield-based ROI method in Chapter 3, even a small yield increase can reduce required attempts by dozens of pieces per 1,000 delivered, which often pays back in tool-hours and schedule stability. This means, you can approve premium process options with a finance-ready justification instead of relying on gut feel.

Supplier Evaluation Checklist — What to Ask Without Sounding Like an Engineer

Supplier evaluation should not be a vibe check. You want evidence that the supplier can manage natural material variability while controlling finish consistency at scale. This means, you can pick a supplier who protects your repeat orders, not just your first sample.

Evidence-based questions that correlate with stable outcomes

- Do you have a defect library (chips, cracks, pits) tagged by root cause (material vs process)?

- Can you show process proof: a short video of roughing → refinement → polishing for a similar geometry?

- How do you sort rough for risk grading and batch consistency (texture, visible fissures, color zoning)?

- What is your inspection method (lighting, magnification, measurement tools) and can you align it with ours?

These questions avoid arguing about ideology and focus on capability. This means, you can select suppliers based on repeatable controls instead of marketing promises.

How-to steps: a sampling strategy that prevents “sample OK, mass production fails”

- Run a pilot (e.g., 30–100 pcs) and record defect categories with photos.

- Confirm acceptance criteria on a “golden sample” signed by both parties.

- Scale in risk tiers: start with lower-risk geometry before high-risk thin or undercut designs.

- Require a process lock: if the supplier changes tooling or workflow, they must notify you before continuing.

This structure reduces the probability of unpleasant surprises when volume increases. This means, you can stabilize quality before you commit to full MOQs and marketing spend.

Compliance Deep Dive — FTC, EU GPSR/REACH, and US Lead/Prop 65 Expectations

If your search intent includes “compliant,” you’re not alone. Jade products often enter regulated environments not because jade itself is restricted, but because jewelry components, coatings, labeling, and chemical exposure rules apply in the destination market. This means, you can prevent customs issues, platform takedowns, and costly relabeling after inventory lands.

United States — FTC Jewelry Guides and treatment disclosure

The FTC’s Jewelry Guides exist to help prevent deceptive practices in marketing jewelry, including gemstone representations. (Federal Trade Commission) If jadeite is treated (e.g., polymer-impregnated or dyed), industry guidance and gem treatment references emphasize disclosure because treatment can affect value and care requirements. (gia.edu) This means, you can reduce misrepresentation risk by requiring written treatment disclosure and aligning your product copy with recognized guidance.

How-to compliance steps (FTC-facing):

- Require the supplier to declare jadeite vs nephrite in writing.

- Require disclosure of treatments and request supporting lab documentation if you sell into markets that scrutinize claims.

- Align product listings so “natural jade” claims are not used when treatments materially affect value or care expectations.

These steps are practical because disclosure problems usually begin at the supplier information stage. This means, you can protect your storefront and avoid refunds caused by claim disputes.

European Union — GPSR (EU) 2023/988 and “safe product” obligations

The EU’s General Product Safety Regulation (GPSR) is now a central framework for consumer product safety obligations and is widely discussed as applying from 13 December 2024. (EUR-Lex) For jewelry brands and importers, the operational impact is typically about documentation, traceability, risk assessment, and responsiveness—especially when products involve skin contact and small parts. This means, you can build a documentation package that supports EU market access instead of scrambling after a platform or authority inquiry.

How-to compliance steps (GPSR-facing):

- Maintain a product file with materials declarations, supplier info, and basic risk analysis.

- Ensure traceability fields exist (batch/lot identifiers, supplier address, economic operator responsibilities).

- Align labeling and warnings with destination requirements, especially for children’s items or products with small parts.

This is about operational readiness, not fear. This means, you can sell into the EU with fewer interruptions and faster issue resolution if problems arise.

European Union — REACH restrictions (nickel release and cadmium limits)

REACH Annex XVII includes restrictions for nickel release in articles intended for direct and prolonged contact with skin, often cited as 0.5 μg/cm²/week, and the test method EN 1811 is widely referenced in the compliance ecosystem. (nickelinstitute.org) REACH-related summaries also note cadmium restrictions for metal parts of jewelry, commonly referenced at 0.01% by weight (100 mg/kg) in applicable contexts. (Compliance Gate) This means, you can specify metal component compliance (not just the stone) and avoid failed lab tests that delay launches.

How-to compliance steps (REACH-facing):

- If your jade is set in metal, require nickel release compliance documentation for skin-contact parts (rings, bracelets, pendants).

- Require cadmium declarations for metal components and coatings where applicable.

- Use third-party lab testing for high-volume SKUs or when selling via platforms that demand compliance documents.

This is a practical way to treat compliance as an input to design and supplier selection. This means, you can avoid rework and returns caused by metal component non-compliance rather than blaming the stone.

United States — CPSIA lead limits for children’s products (if applicable)

If the product is marketed for children (or could reasonably be considered a children’s product), U.S. rules can include strict lead limits, and the CPSC explains that children’s products with accessible components over 100 ppm lead can be considered banned hazardous substances under CPSIA-related provisions. (U.S. Consumer Product Safety Commission) This usually impacts metal findings, coatings, and paints more than jade itself. This means, you can avoid high-stakes compliance failures by classifying your product correctly and controlling accessory materials.

How-to compliance steps (CPSIA-facing):

- Decide whether the SKU is a children’s product based on marketing and intended user.

- If yes, implement material controls for metal and coatings and consider required testing and documentation.

- Work with suppliers who can provide traceable material declarations and consistent plating processes.

This keeps child-focused compliance from becoming an expensive surprise. This means, you can prevent product removals and legal exposure in a high-liability category.

California — Metal-Containing Jewelry Law and Prop 65 warning considerations

California has specific resources discussing metal-containing jewelry and notes that you may still be responsible for Proposition 65 warning requirements if you sell jewelry containing listed chemicals such as lead. (Lead in Jewelry FAQs) Prop 65 warning rules can evolve (including short-form warning requirements), so brands selling into California should treat warning/chemical disclosure as an ongoing compliance process rather than a one-time checkbox. (HQTS) This means, you can reduce downstream relabeling costs and avoid penalties tied to warning non-compliance.

How-to compliance steps (California-facing):

- Map your SKUs sold into California and identify metal parts/coatings likely to trigger lead/cadmium concerns.

- Require supplier material declarations and keep test reports for high-risk items.

- Maintain a Prop 65 review process when formulas, plating, or suppliers change.

This turns compliance into a manageable workflow instead of a recurring fire drill. This means, you can keep listings live and protect your California revenue stream.

FAQ

Which jade is easier to carve: jadeite or nephrite?

In general references, jadeite is listed as harder, while nephrite is often described as tougher, and that toughness can make nephrite more forgiving in complex carving or thin features. (gia.edu) “Easier” in production usually means fewer late-stage breaks and fewer edge chips, which often points toward nephrite for high-risk geometry. This means, you can choose nephrite when stable deliverables matter more than incremental optical premium.

Why did my jade piece crack during carving or polishing?

Cracks can be pre-existing (micro-fissures) and become visible after stress is introduced, or they can propagate due to vibration, localized pressure, or aggressive removal in weak zones. Hard/brittle machining research explains how damage initiation and brittle fracture mechanisms can arise under concentrated contact and sliding interactions. (PMC) This means, you can reduce cracking disputes by requiring rough screening, conservative DFM, and defined acceptance criteria before mass production.

Can CNC guarantee identical results across natural stone?

CNC can guarantee path repeatability, but it cannot guarantee identical internal stone structure across pieces. Natural variability means the same toolpath can produce different outcomes if internal weaknesses differ, which is why process proof, risk grading, and inspection alignment matter. This means, you can get industrial consistency by controlling inputs and acceptance standards, not by assuming the machine overrides geology.

What defects are ‘material reality’ vs ‘process mistakes’?

Material reality often includes natural inclusions, color zoning, and certain internal features, while process mistakes often show up as consistent tool marks, repeatable edge chipping at the same feature location, or burn-like polishing artifacts depending on workflow. The cleanest approach is to define a defect taxonomy with photo examples and agree on what is acceptable for your market segment. This means, you can reduce disputes by turning subjective quality arguments into pre-agreed categories.

.webp)