Introduction

If you’re sourcing jade products for an overseas market, you’ve probably noticed a new kind of question showing up in RFQs: “How do you manage water, wastewater, and environmental impact?” This is not a trend for “big brands only”—more distributors, studios, and cross-border sellers now face ESG screening from platforms, retailers, or end customers, and they push those requirements down to the factory level.

This guide explains the jade process through one specific lens: water. You’ll see where water is used in jade manufacturing, how a closed-loop water recycling approach typically works, what “good control” looks like, and what evidence you can request so your supplier file is audit-ready without turning you into an engineer.

Table of Contents

What Overseas Buyers Actually Need to Know About Water in Jade Manufacturing

Why Water Management Becomes a Procurement Risk

From a buyer’s perspective, water management matters for three reasons: supply risk, compliance risk, and reputational risk. If a supplier’s wastewater handling is unclear, your shipment timeline can be disrupted by inspections, local restrictions, or corrective actions—none of which show up in the unit price.

What “Verifiable” Looks Like for ESG Questions

The second reason is documentation. Many ESG questionnaires look complicated, but the water portion usually comes down to simple, verifiable things: where water is used, whether it is reused, how solids are captured, and how discharge (if any)(GRI 303) is controlled. In other words, water is one of the easiest environmental claims to verify—if the factory is transparent.(CDP)

Why Water Control Also Protects Product Consistency

The third reason is product consistency. The jade process involves cutting, grinding, carving, and polishing, and water is often part of cooling and cleaning. Stable water control helps stabilize tooling performance and surface quality, which means fewer finish disputes and fewer “why does this batch look slightly different?” conversations in jade manufacturing.

Where Water Is Used in the Jade Process (A Stage-by-Stage Map)

.webp)

A Simple Way to “See” Water in Jade Manufacturing

In Jade Manufacturing, water typically touches the jade process in two ways: (1) cooling and dust control during material removal, and (2) rinsing and cleaning during finishing. When a factory maps these water touchpoints clearly, it becomes much easier for you to evaluate sustainability without guessing.

For procurement, the goal is not to force every supplier into the same equipment list. The goal is to make sure each stage has a defined capture point for slurry, a defined reuse or treatment path, and a defined way to prevent uncontrolled discharge.

Cutting & Slicing (Cooling, Kerf Control, and Slurry Capture)

During cutting and slicing, water or water-based coolant is commonly used to reduce heat and manage fine particles. From a buyer’s perspective, the key question is not “Do you use water?” but “Where does the slurry go, and how do you prove it doesn’t go straight to drain?”

A credible eco-friendly jade process will show a predictable collection route from the cutting station to a settling or filtration area. If the supplier can’t show that physical route clearly—via photos, a short video, or a simple flow diagram—it’s a sign that water control is informal.

Grinding & Shaping (Abrasive Slurry and the Biggest Recycling Opportunity)

Grinding and shaping generate a mix of water, abrasive, and mineral fines—often called slurry. In Jade Manufacturing, this is usually the highest-volume “dirty water” stream, so it’s also where closed-loop recycling creates the biggest impact.

For buyers, the practical check is whether the supplier can explain three things in plain language: how slurry is captured at the source, how solids are separated, and how reuse water quality is kept stable enough for consistent results. If those three answers are vague, it typically means the system is hard to scale when your order volume grows.

CNC Carving (Fine Particles, Tool Life, and Filtration Discipline)

CNC carving often uses coolant or flush water to carry away micro-particles and protect tool life. This matters because finer particles are harder to settle, which means filtration quality and maintenance discipline become both a quality factor and an ESG factor in the jade process.

If you purchase intricate patterns or tight-tolerance components, ask how the factory prevents fine particulate buildup from circulating back into the process. A stable filtration routine supports consistent carving performance, and it reduces the risk that “environmental controls” disappear when the workshop is busy.

Polishing (Residues, Rinsing, and Keeping the Loop Efficient)

Polishing can introduce residues from compounds and pads, followed by rinse steps that remove surface residues before drying. An eco-friendly jade process typically focuses on minimizing chemical load, optimizing rinse volumes, and avoiding unnecessary freshwater use while protecting finish quality.

From a buyer’s viewpoint, the red flag is when polishing residues enter the same recycling loop without any plan—because it can overload treatment and make the supplier’s “closed-loop” claim unstable. A mature Jade Manufacturing workflow either controls that stream carefully or separates it when needed.

Cleaning & Finishing (Final Rinse, Drying, and Buyer-Facing Quality)

Cleaning and finishing often include final rinses before drying and packing. This stage is easy to overlook, but it’s where buyers most directly connect “process control” with “product readiness,” especially for pieces that must arrive clean and presentation-ready.

For ESG review, your question can stay simple: can the supplier show controlled cleaning steps that avoid unnecessary freshwater use, while still meeting your cleanliness standard? If they can explain the steps, show the station setup, and describe where the used water goes, it usually indicates the entire jade process is managed with the same discipline.

Closed-Loop Water Recycling in Jade Manufacturing (How the System Works)

What “Closed-Loop” Means in Practical Jade Manufacturing

A closed-loop system means the factory treats process water on-site and reuses it back into production, instead of running “once-through” water that becomes wastewater immediately. In sustainable Jade Manufacturing, this approach is often the backbone of a green factory standard because it reduces freshwater demand and lowers wastewater risk.(IFC EHS Guidelines)

For buyers, the key benefit is simple: a closed-loop system turns water from an uncontrolled cost and compliance risk into a managed process. It also makes supplier verification easier, because you can ask for a diagram, photos, and basic logs that match the physical system.

Step 1 — Collection (Return Flow from Each Station)

Process water returns from cutting, grinding, CNC, and polishing stations into collection channels or sumps. A practical design goal is to prevent heavy slurry from spreading across the workshop and to route it predictably into the treatment loop.

From a procurement perspective, collection is where “recycling” either starts or fails. If the return path is unclear or relies on manual dumping without containment, the system is harder to scale and harder to audit.

Step 2 — Separation (Settling for Heavy Mineral Fines)

Settling tanks slow the flow so heavier mineral particles drop out. This is a low-complexity step, but it is very effective for stone fines and it significantly reduces the load on downstream filters in Jade Manufacturing.

Buyers don’t need tank dimensions to evaluate credibility. What you do need is a clear explanation of where settled sludge goes, how often it is removed, and how the supplier prevents overflow or bypass when production is busy.

Step 3 — Filtration (Coarse-to-Fine Stages)

After settling, filtration removes remaining suspended solids. Many workshops use staged filtration—coarse screens first, then bag filters, then finer cartridges—so they can keep reuse water workable without constant clogging.

The most buyer-relevant detail here is maintenance discipline. A supplier who cannot describe filter change frequency, cleaning routines, and how they detect clogging is often operating “reactively,” which creates both quality variability and ESG uncertainty.

Step 4 — Reuse Stability (Quality Control for Consistency)

Reuse water does not need to be drinking-water clean to support the jade process. However, it should be stable enough that machining performance and polishing outcomes stay consistent across batches.

In an eco-friendly jade process, the objective is controlled reuse: predictable solids capture, predictable water clarity for the intended step, and predictable maintenance. This is also where you can align environmental control with yield and finish consistency.

Step 5 — Monitoring (What to Track and What to Share)

When buyers ask, “What do you monitor?”, a practical answer focuses on simple metrics tied to risk. Common examples include turbidity or suspended solids (how cloudy the water is), pH (which can affect corrosion and chemical behavior), and documented maintenance cadence.

You don’t need the supplier to disclose every internal number to prove control. What you do need is evidence that monitoring exists—such as a log template, a sampling routine, and photos of the system—so your sourcing decision is defensible for ESG review.

Wastewater, Sludge, and Residue Management (The Part Buyers Worry About)

Why This Topic Drives ESG “Red Flags” in Jade Manufacturing

Even with recycling, most Jade Manufacturing operations will generate residual waste streams: settled sludge, spent filters, and residues from polishing and cleaning. This is the area where many suppliers become vague, and that vagueness becomes your procurement problem—because ESG reviewers will ask what happens after solids are captured.

From a buyer’s perspective, you’re not looking for a perfect “zero impact” claim. You’re looking for controlled handling, clear routing, and evidence that the factory can explain the system consistently during onboarding or an audit.(ISO)

Sludge Handling (Dewatering, Storage, and Traceability)

Sludge is typically mineral-heavy and can be dewatered to reduce volume and improve handling. A buyer-friendly green factory standard focuses on contained storage, clear labeling, and a simple traceability practice—such as dates, removal frequency, and transfer records—so waste management is intentional rather than improvised.

If you’re comparing suppliers, ask one straightforward question: “Can you show where sludge is stored and how it leaves the site?” A credible supplier can walk you through the route, show labeled containers, and provide at least a basic record format that your team can file.

Discharge Control (If Any) and How to Keep It Verifiable

Some workshops run with near-zero discharge, while others may discharge a controlled portion depending on local infrastructure and permits. From your perspective, the “right” approach is the one that is documented: what is discharged (if anything), under what conditions, and what basic checks are performed to reduce risk.

If a supplier discharges to a municipal or industrial system, the key is pretreatment logic—solids capture first, then controlled routing—so slurry does not enter drains unchecked. You don’t need to become a regulatory specialist, but it’s reasonable to request a simple explanation of how discharge is managed and what evidence can be shared.

Spent Filters, Polishing Residues, and Cleaning Waste (Keeping the Loop Stable)

Spent filters and polishing residues often contain fine solids and process compounds, and they can overload a recycling loop if handled casually. In a mature eco-friendly jade process, these residues are either handled as a controlled waste stream or captured at dedicated points so the main loop remains stable.

For buyers, the practical test is consistency: does the supplier have a defined routine for filter changes and residue handling, and can they show it in a way that matches what you see on-site or in a video walkthrough? If handling relies on “we’ll deal with it when it happens,” the risk increases when production volume ramps up.

Chemical Responsibility in an Eco-Friendly Jade Process

Why Chemicals Matter in Jade Manufacturing Water Systems

When buyers hear “eco-friendly,” they often think only about water quantity, but water quality in the jade process is strongly influenced by chemicals. Coolants, polishing agents, and cleaners can change how easily water can be recycled, how stable reuse quality remains, and how complicated residue handling becomes in Jade Manufacturing.

From a procurement standpoint, chemical control is less about “using nothing” and more about having a controlled system. You want a supplier who can explain what is used, why it is used, and how the workshop prevents those materials from turning a recycling loop into a hidden risk.

What Buyers Should Request (Without Becoming a Chemist)

A practical request is a short list of the main consumables used in the jade process—coolants, polishing compounds, and cleaning agents—plus confirmation that SDS can be provided when needed. This makes your supplier file defensible, especially when your customer or platform asks for hazard transparency.

You can keep it buyer-friendly by focusing on three items: an SDS list, storage/labeling photos, and a basic handling routine (how spills are prevented and how residues are contained). These three items usually reveal whether the supplier treats ESG as a process or as a marketing line.

Substitution + Discipline (A Realistic Green Factory Approach)

A green factory approach usually combines substitution and discipline. Substitution means choosing lower-impact consumables where feasible without sacrificing finish quality, while discipline means preventing overuse, preventing spills, and keeping high-residue chemicals out of the reuse loop unless the treatment system is designed for it.

This matters for you because chemical discipline reduces variability. If two suppliers produce similar samples, the one with better chemical control is often the one that stays consistent when you scale orders—because their jade manufacturing process is less dependent on ad-hoc adjustments.

Water Efficiency KPIs Procurement Teams Can Compare Across Suppliers

Why KPIs Make Jade Manufacturing ESG Reviews Faster

The easiest way to compare suppliers is to ask for a small set of water KPIs that can be verified. You don’t need a perfect life-cycle assessment to make a good sourcing decision; you need consistent metrics and a willingness to share evidence that matches the physical reality of the workshop.

In Jade Manufacturing, the best KPIs are the ones that procurement can understand and suppliers can actually measure without “creative reporting.” If a supplier can’t explain how they calculate a metric, it’s safer to treat the number as marketing rather than management.

KPI 1 — Water Reuse Rate (Closed-Loop Performance)

Reuse rate asks: what portion of process water is reused in the closed-loop system over a defined period? A higher reuse rate often indicates a more mature eco-friendly jade process, but the number matters less than whether the supplier can explain the boundary conditions—what water streams are counted, and what is excluded.

Buyer tip: ask for a one-week snapshot that shows freshwater input, estimated reuse circulation, and where losses occur (evaporation, carry-out on parts, sludge removal). A supplier who can show a simple water-balance view is usually easier to audit and more reliable to scale.

KPI 2 — Freshwater Intensity (Scale Risk Indicator)

Freshwater intensity asks: how much new freshwater is added per batch, per shift, or per kilogram of output (choose one unit and keep it consistent across suppliers). This metric helps you understand scale risk—if you double your order, will freshwater demand double, or does the recycling loop absorb growth efficiently?

For procurement, the goal is comparability, not perfection. Pick a unit that fits your buying pattern (for example, per shift if you order by production capacity, or per kilogram if you order by weight) and require the same unit in every supplier response.

KPI 3 — Solids Capture Effectiveness (Slurry Control and Proof)

Solids capture effectiveness is about preventing slurry and mineral fines from leaving the process uncontrolled. Because suppliers may not have a single “capture percentage,” evidence often matters more than a number: settling/filtration design, maintenance cadence, and visual proof of contained sludge handling.

Buyer tip: request two photos and one record template—(1) the settling/filtration area, (2) labeled sludge/residue storage, and (3) a maintenance or removal log format. These are low-friction asks, and they quickly separate “real control” from “we recycle water” claims.

Red Flags vs. “Good Signs” When Reviewing KPI Answers

Red flags include: “We recycle water” with no diagram or photos, no mention of sludge handling, and no maintenance routine for filters and tanks. Another red flag is a KPI number that sounds impressive but has no defined time period or boundary—because it cannot be compared or verified.

Good signs include: a clear definition of what is measured, a repeatable reporting cadence, and evidence that the KPI is tied to a working process (logs, maintenance routines, and visible treatment infrastructure). In sustainable Jade Manufacturing, maturity shows up as clarity and consistency, not as perfect-sounding claims.

Audit-Ready Proof for Supplier Qualification

Why “Proof Packs” Reduce Risk in Jade Manufacturing Sourcing

If you’re building a supplier file for an overseas brand, distributor, or platform that asks for ESG readiness, you want proof that matches your internal workflow. The best Jade Manufacturing suppliers make verification easy: they present the water system like a process, not like a promise.

From the buyer seat, “audit-ready” doesn’t mean exposing trade secrets. It means the supplier can show consistent, repeatable evidence—so your decision is defensible if compliance, legal, or a downstream customer asks for substantiation.

What a Buyer-Friendly Water & ESG Proof Pack Can Include

A practical proof pack for the water side of the jade process can include: a simple process-flow diagram, photos of collection/settling/filtration areas, a basic monitoring log template, a maintenance checklist, and a waste handling record template showing how sludge and spent filters are managed. These materials are usually enough for a first-pass ESG screen without slowing your sourcing timeline.

If you want the pack to be comparable across multiple suppliers, request the same structure from everyone. Standardization is what turns ESG review from “subjective impressions” into a fast, repeatable procurement step.

Remote Verification That Still Feels “Real”

If you prefer a remote-first approach, request a short live video walkthrough that follows the water touchpoints along the jade process—cutting, grinding, CNC, polishing—then ends at the recycling/treatment area and the labeled residue storage area. This route quickly shows whether the system is real and controlled.

After the walkthrough, ask for a small follow-up package: 8–12 photos labeled by station plus one sample template record. This keeps the request reasonable for the supplier while giving your team enough evidence to file and reference later.

How Procurement Can Document Due Diligence Without Overcomplicating It

A simple way to document due diligence is to keep a one-page checklist: what you requested, what you received, and what gaps remain. In practice, this protects you more than a long narrative, because it shows you asked the right questions and evaluated the evidence consistently.

If your organization uses a formal responsible sourcing approach, align your proof pack with a recognized due diligence logic: identify risk, request evidence, and track corrective actions when needed. This is the same structure many global buyers use across supply chains, not just for Jade Manufacturing.

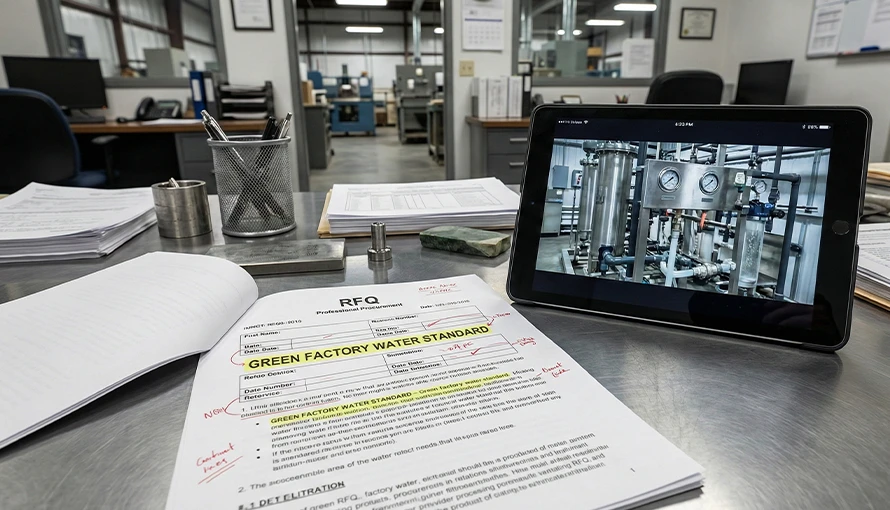

Green Factory Standard You Can Put Into Your RFQ (Buyer-Friendly)

How to Use This Section in Procurement

Buyers often ask, “Can you give me a green factory standard I can copy into my RFQ?” The goal is not to turn your RFQ into a technical manual—it is to set minimum expectations that filter out suppliers who cannot operate transparently in Jade Manufacturing.

The best RFQ language is specific enough to verify, but simple enough that suppliers can respond quickly. To keep your process fast, ask for two kinds of evidence: (1) visual proof (photos/video), and (2) basic records (templates or samples with sensitive details redacted).

Minimum Requirements (Baseline Controls Any Credible Supplier Should Meet)

Water mapping and capture: The supplier should identify where water is used across the jade process (cutting, grinding, CNC, polishing, cleaning) and show how slurry is captured before it reaches any drain. Evidence can be a simple flow diagram plus photos of collection routes and the treatment area.

Defined recycling/treatment loop: The supplier should operate a defined closed-loop recycling or treatment system (even if partially closed-loop) that includes collection, settling, and filtration. The key for buyers is that the loop is stable and documented, not that it uses a specific brand of equipment.

Residue and sludge management: The supplier should store sludge/residues in contained and labeled areas and maintain a basic routine for sludge removal and filter changes. A credible supplier can show the storage area and provide a simple record format that matches what you see in the workshop.

Preferred Requirements (For Brands With Stricter ESG Targets)

Measurable KPIs: The supplier tracks reuse rate and freshwater intensity over time and can share a snapshot report for a defined period (e.g., one week or one month). This makes ESG reviews faster and helps you compare suppliers side-by-side.

Monitoring and maintenance cadence: The supplier maintains monitoring and maintenance routines for tanks and filters and can share redacted examples of logs. In practice, this is one of the strongest indicators that the eco-friendly jade process will stay stable when orders scale.

Stream separation when needed: If polishing residues or cleaning chemicals create high loads, the supplier applies separation or dedicated capture points so the main recycling loop remains efficient. For buyers, this reduces the risk of “closed-loop in theory, overflow in reality.”

Verification Method (What Evidence Counts and What’s Easy to Review)

To keep verification simple, require a small, repeatable evidence set: a one-page water flow diagram, 6–10 labeled photos (stations + recycling area + residue storage), one monitoring or maintenance template, and one waste handling template. This is usually enough to establish credibility without slowing negotiation.

If you want to be stricter, add one remote verification step: a 10–15 minute video walkthrough that follows the water touchpoints and ends at the recycling and residue storage areas. The goal is not to “catch” a supplier, but to confirm that what’s documented matches what exists.

Copy-and-Paste RFQ Clause (Buyer-Friendly Language)

RFQ requirement (Water & Waste Control): Supplier must describe water use points in the jade process and provide evidence of slurry capture, water recycling/treatment, and residue/sludge handling. Supplier must provide (a) a simple process flow diagram, (b) photos/video of collection + settling/filtration + labeled residue storage, and (c) basic templates or sample records for monitoring/maintenance and waste handling (redaction allowed).

Verification: Buyer may request a remote walkthrough prior to bulk order confirmation. Supplier agrees to respond to ESG water questions in a consistent format for supplier onboarding and audit purposes.

Conclusion

If you are evaluating suppliers and want a faster way to qualify environmental readiness, treat the water system like any other capability: define your requirements, ask for evidence, and compare responses side-by-side. This approach reduces risk and shortens the time between sampling and bulk purchase in jade manufacturing.

For Jade Mago buyers, we recommend using a simple onboarding request: your product type, finish requirements, estimated order volume, and your ESG water questions in one message. We can then respond in the same structure—where water is used in the jade process, how reuse is controlled, and what proof materials can be shared for your supplier file—so your review is straightforward and your internal approvals move faster.

FAQ

Does water recycling affect finish quality?

It can, if reuse water becomes unstable or overloaded with fine particles. In a controlled eco-friendly jade process, reuse water quality is managed so machining and polishing remain consistent, and the factory can explain how they prevent solids from returning to critical steps.

How do you prevent cross-contamination?

In jade manufacturing, cross-contamination is usually about residues and particle size. Practical controls include separation of certain rinse streams, staged filtration, and clear routing so polishing residues do not overload the same loop used for cutting and CNC operations.

What can you provide if our compliance team asks for proof?

A credible supplier should be ready with a simple system explanation plus evidence: flow diagram, treatment area photos, monitoring/maintenance templates, and a clear description of sludge/residue handling. If the supplier cannot share anything, that is typically a sign that the system is informal.

-900x375.webp)