Introduction

At JADE MAGO and across the wider gemstone processing industry, the precision of Tumbling Polish is the finishing factor that makes or breaks products.” For centuries, master polishers worked long hours polishing every piece of Nephrite or Jadeite to achieve that iconic greasy or vitreous luster that defined centuries ago jade processing techniques. But due to changes in B2B markets that require scaleability without compromising quality standards, JADE MAGO now uses tumble polish technology that has revolutionized production capabilities at JADE MAGO and beyond.

This article delves into the technical details of automated polishing systems. We will discover how modern engineering allows us to process hundreds of kilograms of rough stone into market-ready gems with consistent quality. Understanding this process is essential for factory owners, wholesale buyers and supply chain managers when making informed decisions regarding procurement and production standards.

Table of Contents

Jade Surface Engineering Has Evolved Over Time

Transitioning from hand carving tools to industrial machinery was not an overnight process. At first, our factory floor workers viewed automated tumblers with caution – believing they couldn’t replicate the “warmth” of hand polishing stone surfaces by machine. Over time however, we learned that while machines cannot match human hands in terms of creativity or design of carvings, they excel far beyond us when it comes to consistency and uniformity for beads, cabochons, or simple geometric forms.

From Manual Friction to Mass Production

Histories of jade processing used bamboo tools, leather strips and loose abrasive mud; artisans then applied pressure depending on the stone’s feedback to vary pressure with each pass of pressure applied by hand – an effective but slow method that often led to human error and fatigue–often leading to uneven surfaces or missed spots known in trade as “orange peel”. Rotary and vibratory tumblers changed this equation significantly by replacing manual friction from human arms with steady motor energy for greater consistency in production.

Automated jade processing not only speeds up work; it also ensures uniform outcomes. When we load 50 kilograms of jade beads into a barrel, we know each bead will receive exactly the same friction and contact time, an essential aspect of modern volume manufacturing that allows brands to guarantee consistent products to clients while building commercial trust in gemstone markets.

Definition of Modern Tumbling Polish

Many outside of the industry often conflate industrial tumbling with hobbyist rock tumbling, both being passive processes with uncertain results. Industrial tumbling polish is a precise science involving fluid dynamics, abrasive geometry and frequency modulation; we utilize specific calculating formulas to ascertain stone to media ratio and required water volume.

Modern stone shaping processes utilize advanced lining materials, like polyurethane, to prevent contamination and damage to our barrels, as well as sophisticated control panels that enable us to adjust rotational speed or vibration intensity at will. Thanks to this level of control, we can aggressively shape a rough stone in the morning before gradually creating high gloss polishes in the afternoon – effectively turning geological raw material into commercial commodities with predictable margins.

Mechanicals of Motion: Rotary Vs Vibratory Systems

To gain a full appreciation of how we achieve high-volume output, it’s necessary to examine our machinery itself. At our facilities we utilize two main types of machines – rotary tumblers and vibratory tumblers – with each serving specific purposes in production line; it is crucial that technicians or buyers understand this difference so as to maximize production success.

Rotary tumblers are notoriously aggressive

Rotary tumblers are the mainstay of initial shaping phase. Imagine a cement mixer filled with rocks and grit, but lined with rubber instead. As the barrel rotates, material climbs its walls until gravity takes control – creating high impact collisions as it slides back down, creating significant friction.

Rotary tumblers are ideal for the “coarse grind” stage of jade processing. When we receive raw material from being cut with a saw, its edges may be sharp and jagged; rotary tumblers efficiently round off these edges while their cascading action removes material quickly. Unfortunately, however, this method may be too aggressive for final polishing stages; impact from its rotating action may cause microfractures in its crystal structure; thus we primarily employ these devices for shaping and smoothing initial rough forms before moving to more delicate methods of shaping and smoothing them over more aggressive ones.

Vibratory Tumbler Precision

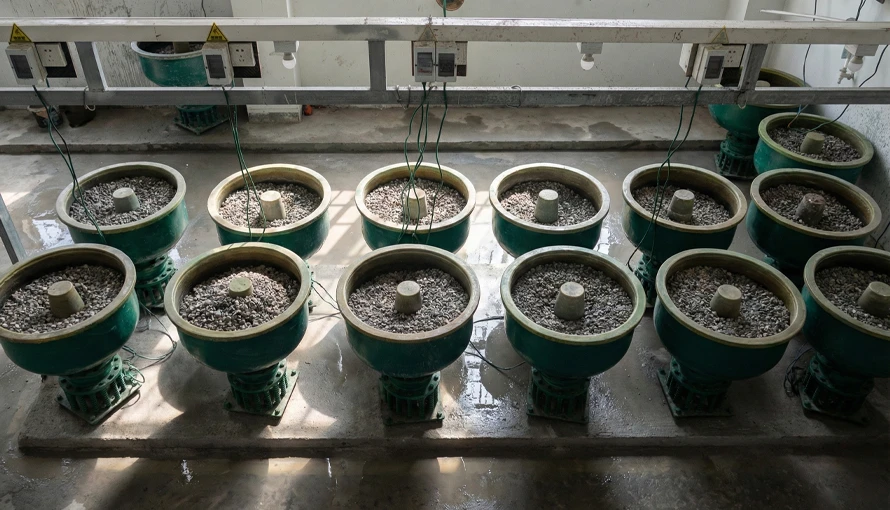

Vibratory tumblers represent a revolutionary advancement in finishing technology. Instead of the violent collisions experienced with rotary systems, vibratory bowls use high frequency vibration to shake all loads within them at the same time – providing constant abrasive contact between jade and its abrasive media without violent collisions between objects in rotary barrels.

Vibratory polishers are an ideal way to apply semi-finished goods. As no stones fall or collide during tumbling, there’s less of a risk of cracking or bruising the jade; vibration allows abrasive media to reach recesses and internal curves missed by rotary tumblers; JADE MAGO has chosen this method as their go-to choice for final three stages of polishing as it preserves stone shape while refining surface to a mirror finish while conserving integrity of shape while refining surface to a mirror finish surface; according to industry leaders like Lapidary Journal Jewelry Artist vibratory systems can reduce processing time by 50% compared with their counterparts while maintaining higher fidelity of original shape preservation compared rotary systems while simultaneously increasing original shape fidelity compared with their counterparts.

Abrasive Media Science

Machines provide energy, but media does the work. “Media” refers to the abrasive shapes we mix with jade for processing; choosing an optimal media mix requires balancing density, shape and abrasive composition to achieve success.

Ceramic Media and High-Density Impact Resistance Testing Solutions

Ceramic media is used as the standard in jade processing to facilitate grinding and smoothing stages, due to its high density. Jade is a tough material; Nephrite in particular has an interlocking fibrous structure which makes it particularly resistant to fracture. To smooth it down effectively requires heavy media that exerts enough pressure.

As part of our initial process, we utilize angle-cut ceramic cylinders or triangles with angled edges that allow our media to cut deep into the surface of jade, removing saw marks and imperfections. Its hardness must match that of its stone material; otherwise it might chip off instantly without impacting it at all; we constantly monitor wear rate of our ceramic media to prevent it from shrinking too rapidly and lodging inside bead holes – this can become a production headache that must be mitigated through rigorous screening protocols.

Plastic and Organic Media for Final Polish

As we move toward our final tumbling polish, we shift away from heavy ceramic media towards lighter plastic or organic media. Plastic media consists of polyester resin mixed with silica or aluminum oxide for fine abrasive action; its lower density helps cushion stones against one another while still delivering an aggressive action.

For the ultimate high-gloss finish, we utilize organic media such as walnut shell or corn cob grit treated with polishing compounds for dry processing. This dry processing technique generates heat via friction. The heat encourages the polishing compounds–often tin oxide or cerium oxide–to bond briefly with the surface of jade to create a chemical-mechanical polishing effect, similar to “water glazing” found in high-end optics manufacturing; giving our jades that wet, radiant look even when completely dry! This final stage ensures their wet, glowing look even when perfectly dry!

The Progressive Grit Strategy

At its core, creating the ideal finish requires following one simple rule: never leave a scratch deeper than what the next step can remove. Rushing initial stages won’t cover any underlying imperfections; we use a four-stage cycle on most commercial jade products which ensures surface structure refinement from jaggedness to microscopically smooth surfaces.

Coarse Grinding: Establishing Geometry

At first, tumbling polish involves coarse silicon carbide grit ranging from 60 to 90 mesh – usually the most aggressive phase – with its aim being not just making the stone beautiful but defining its shape as well. For rough jade that has been cubed or sliced roughly, this stage wears away sharp edges while creating an even contour.

We operate this cycle in rotary tumblers for 24-48 hours. As soon as the mixture of water, grit, and stone thickens up quickly with mud, operators must closely monitor its viscosity if too much sludge accumulates; otherwise grinding will stop due to floating stones rather than grinding against an abrasive. At this stage we regularly flush barrels so fresh grit can reach stone surfaces – creating the geometry on which all subsequent steps rely.

Intermediate Refining of Surface Area

Once the shape has been determined, we must remove any deep scars left by coarse grit. At this stage we switch between 220- and 400-grit cycles, often switching from rotary to vibratory tumblers in order to protect stones from impact fractures; jade surfaces begin to transform from rough white into smooth matte textures as we progress.

At this stage, quality control is of utmost importance. If a batch moves forward too early from 60-grit stage, the deep scratches visible under magnification may remain. We refer to this practice as “undercutting,” and it ruins the value of final product. Loupes are used daily to inspect random samples from barrel and ensure uniform “frosted” appearance across its entirety – consistency here determines reflection clarity and therefore improves value of final product.

Pre-Polish Matte Finish

The Pre-Polish Stage is the final mechanical abrasion step before polishing begins. We usually utilize 1000-1200 mesh aluminum oxide powder as its fine particles will remove small amounts of material, leaving jade feeling silky soft to touch after this stage has completed.

Cleaning both stones and barrels thoroughly between intermediate and pre-polish stages is of utmost importance. Even just a single grain of 220 coarse grit remaining in a barrel during 1200 grit can ruin days of work by acting like an invisible diamond scratching every stone that passes over it. Our factories adhere to stringent hygiene protocols using separate barrels for coarse and fine stages to eliminate cross-contamination risks completely; this discipline sets professional jade processing facilities apart from amateur workshops.

Chemistry of Polishing Compounds

After days of grinding, our stones become smooth but dull. To achieve the distinctive “glassy” or “greasy” luster characteristic of high-grade jade, however, we must go beyond simple abrasion into tribochemistry – a process where chemical reactions, heat and friction combine to alter its surface molecularly.

Oxide Reactions and Luster

At this final tumbling polish stage, specific metal oxides are utilized. While Cerium Oxide has long been the industry standard for quartz-based stones such as Agate or Jasper, jade often requires different considerations. Nephrite jade is often more suitable than Cerium Oxide due to its soft yet tough nature; for best results we often utilize Chrome Oxide or Tin Oxide due to their specific hardness and chemical affinity with its structure.For details, refer to the Mohs Hardness Scale and Abrasive Suitability Chart.

friction generates localized heat points which cause jade to rub against carrier media coated in these oxides, creating localized hot spots which in turn cause its surface to flow microscopically, filling even its tiniest pores. Chrome Oxide’s bright green hue makes it perfect for producing the high-gloss “mirror finish” on darker green nephrite; however, its use on lighter stones such as white Hetian jade or icy Jadeite requires high grade Tin Oxide or an Aluminum Oxide blend in order to prevent color contamination while creating brilliant shines that leave an impressionful shine behind.

PH and Surfactant Management Options Available

Water chemistry plays an integral part of this process. The pH balance in our polishing tanks ensures that polishing compound remains in suspension, with too acidic or basic water having an adverse impact on its effectiveness. We ensure a neutral pH level balance.

Surfactants, or specialty soaps, are added into our polishing mix as specialized agents that serve two key purposes. First, they reduce surface tension of water to allow polishing slurry to cover every millimeter of jade even inside any holes drilled for it. Second, these agents provide lubricity; friction should occur without creating too much heat build-up so as to “burn” or discolor stone; the surfactants act as coolants/lubricants keeping action smooth and consistent – the balance of chemistry/mechanics being what truly defines efficiency of jade processing lines.

Fluid Dynamics And Water Management

Water is the unsung hero of tumbling. A 500 kilogram industrial tumbler uses water as the energy transfer medium; therefore, we don’t simply fill our barrel to capacity but must calculate how much liquid must be added in order to create the optimal “slurry.”

Viscosity and Cushioning of Fluids

If the slurry contains too much water, the abrasive sinks to the bottom, resulting in excessively hard collisions between stones that lead to bruises. Conversely, too little water results in solid blocks rotating without internal movement–neither of these conditions allows polishing to take place.

At our modern plants, we aim to achieve a creamy consistency similar to milkshake. This viscosity provides a cushioning effect and keeps abrasive particles suspended, keeping them constantly in contact with jade’s surface while working effectively every second the machine runs. Flow meters and automated dosing systems in these plants help us ensure this ratio remains constant throughout 24-hour cycle while compensating for evaporation or build-up of sludge.

Wastewater and Sustainability

Modern manufacturing demands responsibility. Jade processing results in the creation of a sludge which contains rock dust, spent abrasive, and chemical residues; previously this would simply have been washed away; today however, environmental regulations and corporate social responsibility demand more from us.

JADE MAGO facilities utilize sedimentation tanks and filtration systems to capture heavy solids from used slurry, treat, pH balance, and recycle it back into our tumbling lines. Any remaining solid waste is dried and disposed of according to industrial waste standards – not only reduce our environmental footprint but also lower operational costs by decreasing water consumption; making us an attractive solution for B2B clients who prioritize ethical supply chains when purchasing products.

The Economics of Automation: A Cost-Benefit Analysis

Transitioning from manual to automated polishing is more than just an upgrade; it involves restructuring of your entire cost model. Traditional processing determines costs per piece – for instance, for every 1000 beads processed you pay one master polisher to perform 1000 individual operations – creating a linear cost curve which inhibits true scaling. Automated polishing enables true scaling.

Breakthrough the Linear Cost Barrier

Automated systems alter calculations from “per piece” to “per kilogram.” A 200-liter vibratory tumbler doesn’t care whether or not it is polishing 50 large pendants or 5,000 small beads, as energy consumption, water usage, and media wear remain roughly equal for full loads – this allows us to decouple production volume from labor costs.

Mass Tumbling Polish can reduce finishing costs for Nephrite beads by an estimated 70% over traditional hand-polishing, providing manufacturers with significant cost savings compared with hand polishing. This margin allows manufacturers to invest more in procuring higher quality rough stones knowing their processing costs will remain predictable and predictable costs; which translates to competitive wholesale pricing without any compromise to quality standards.

Time vs. Throughput

One cost reduction strategy involves time. A master polisher might finish an expensive bangle in four hours while its tumbling cycle could take four days; but throughput tells an entirely different tale – during those four days, the master polisher could produce only 10 pieces while 500 are produced by the machine!

This shift requires an adjustment in supply chain management. We advise our clients to adopt a “batch mindset.” By batching orders together we maximize efficiency of tumblers and ensure they run at maximum capacity; batching orders also eliminates rush fees associated with manual labor as they ensure steady product entering the market.

Troubleshooting Common Defects in Motors

Even with advanced machinery, things can still go wrong. JADE MAGO stands apart as a specialist by understanding defects to identify early any that arise during automated jade processing – particularly issues such as Orange Peel effect and Bruising that frequently arise during automated processing. Catching them early could save tons of material.

The Orange Peel Effect

“Orange peel” refers to surfaces with uneven shine that resemble the skin of citrus fruit. Reflected light refracts differently when bounced back; hand polishers may experience inconsistent pressure while tumble polishers often suffer undercutting issues that create these irregular surfaces.

This can happen when polishing time is too long or polishing compound generates too much heat, leading to too much wear on softer parts of stone’s structure at an alarmingly fast rate. Nephrite contains aggregate fibers; over-polishing exposes this grain structure. To rectify this, rather than adding polish again we should step back towards fine 1200-grit grinding to flatten surface before moving forward with shorter, cooler final polishes.

Impact Fractures and Bruises

Bruising appears as white crescent-shaped marks on the surface of stone that indicate subsurface fractures caused by impact, typically found on Quartz and harder varieties of Jadeite. It usually indicates an imbalance of fluid dynamics.

When the viscosity of the slurry drops too low, stones do not receive sufficient cushioning and they collide with either the walls of the tumbler or each other. To counteract this effect, we increase the ratio of small plastic pellets in our mix which act as shock absorbers; further thickening it by adding clay-based suspension agents ensures stones “swim” rather than crash through it. Regular inspection of barrel linings must also take place as any wear or tear exposes steel shells that could shatter instantly upon contact; regular inspection will expose steel shells that shatter instantly upon collision exposing its steel shell exposing steel shells which could shatter stone instantly upon contact with steel shell exposed steel shells which then shatter stones instantaneously upon contact resulting in instantaneous shattering stones shattering instantly upon contact by contact between steel shell and stone surfaces linings exposed.

Future of Jade Processing Industry projected growth

As we look to the future, jade processing industry will undergo change. With digital intelligence being integrated into existing analog machines, precision control and hybrid technologies will become part of jade processing’s future.

Nano-Polishing and Ultrasonics

At present, we are conducting experiments with ultrasonic-assisted tumbling. This technology employs high-frequency sound waves introduced into slurry to form cavitation bubbles which implose against jade surface more effectively than any brush or media could. This microscopic action ensures thorough cleaning out of pores on stone surface.

Nano-abrasives-polishing compounds with nanometer-sized particles-can produce surfaces with optical perfection. While currently expensive, this technology could become standard practice for processing high-value gemstones. Pushing beyond our conception of what constitutes “flawless,” it might change how gemstones are processed altogether.

Sorting and Quality Control using Artificial Intelligence.

Human eyes should be our next target to overcome. Sorting rough stones and inspecting finished goods are often done manually; however, optical sorting machines equipped with machine learning algorithms have recently begun appearing in the market and these systems can analyze color, translucency, and surface defects of thousands of stones every hour.

Integrating these systems with our tumbling lines enables us to establish an automated feedback loop. If an optical sorter detects a higher than desired percentage of scratches in a batch, it can signal tumblers to adjust speed or cycle time accordingly for the next load. JADE MAGO envisions smart manufacturing as its future–an amalgamation of geological beauty and industrial intelligence.

Conclusion

The transformation of jade processing through modern tumbling polish technology is a tale of adaptation. We have taken an ancient material associated with ancient tradition, applied the rigorous standards of modern engineering, and found no loss in soul but rather increased accessibility for jade users.

By mastering media, mechanics, and chemistry we enable jade’s natural beauty to be produced at scale that meets global demand. Understanding this process for retailers, wholesalers, designers is the key to procuring superior products – guaranteeing every polished bead and pendant produced is part of a process defined by precision, consistency and volume.

Frequently Asked Questions

Is automated tumbling polish as effective as traditional hand polishing?

For geometric shapes like beads, cabochons, and simple pendants, automated tumbling is actually superior to hand polishing. It offers unmatched consistency across thousands of pieces, ensuring uniform luster without human error. However, for intricate carvings with deep undercuts, we still recommend a hybrid approach combining vibratory finishing with manual detailing.

What is the typical lead time for a bulk tumbling order?

Unlike hand polishing, which is linear, tumbling is a batch process. A full 4-stage polishing cycle typically takes 5 to 7 days to complete, regardless of whether the batch is 50kg or 500kg. This allows for rapid turnaround on high-volume orders compared to the weeks required for manual labor.

Can all types of jade be processed using vibratory tumblers?

Most varieties, including Nephrite and Jadeite, respond beautifully to vibratory tumbling. The key is adjusting the media density. Harder stones require ceramic media for shaping, while softer or more brittle materials may require a higher ratio of plastic cushioning media to prevent impact fractures. Our technicians adjust the “recipe” based on the specific Mohs hardness of your rough stone.

-900x375.webp)