If your purchase order says “jade,” you are not specifying a mineral. You are buying into a trade term that can refer to jadeite or nephrite, and those two materials do not behave the same in value, verification, supply consistency, or downstream claims. Modern gemology treats “jade” as a generic term for jadeite and nephrite (and sometimes other “jade-like” materials under specific conditions), which is exactly why procurement needs to be more precise than marketing language.

This article is written for B2B buyers who need enforceable specs, predictable production, and claim-safe documentation. You will walk away with a practical framework that connects cause → consequence → control, and then turns that control into copy/paste PO terms and contract clauses that reduce disputes.

Table of Contents

Executive Takeaways for Procurement

Procurement risk starts when a supplier uses the word “jade” as if it were a single material grade. That ambiguity is not a minor technical detail, because it blocks pricing comparability and invites disputes over what was actually delivered. The fix is not “learn gemology,” because procurement systems scale through specs and workflow, not personal expertise.

You can control jade procurement with a 3-layer system. First, lock material identity (jadeite vs nephrite) in writing and tie it to lot traceability. Second, lock treatment disclosure (what was done to the stone and how it will be verified). Third, lock quality + tolerances in measurable terms that survive production variability.

-1.webp)

Decision Framework: Control Identity First, Then Treatment, Then Quality

Most “bad jade deals” happen because buyers try to negotiate quality and price before they define identity and treatment. That sequence is backward, because the same-looking piece can be a different mineral, or a treated version of the same mineral, and either change can radically alter value and claim risk. Once identity and treatment are written down, you can finally negotiate quality with clear acceptance criteria.

The 3-Layer Control System (What You Control vs What You Can’t)

Layer 1 — Material identity. You are controlling which mineral family the product is made from, which is the foundation of truthful labeling and many verification decisions. GIA’s gemology references describe jadeite and nephrite as different mineral species with different internal structure and chemistry, which is why identity matters as a starting point.

Layer 2 — Treatment disclosure. You are controlling whether the supplier must disclose bleaching, polymer impregnation, dyeing, or combinations, and which test method will be used when required. Jadeite is frequently treated in the market, and polymer impregnation can be difficult to detect by simple inspection, so relying on “looks fine” is not a procurement strategy.

Layer 3 — Quality and tolerances. You are controlling the business definition of “acceptable” by specifying color range, translucency targets, defect definitions, dimensional tolerance, and finish standards. Those terms are where you prevent endless arguments, because you define what happens when reality deviates.

The Buyer’s Shortcut: If You Only Do One Thing

If your team is time-constrained, make one change: update your PO to require identity + treatment + traceability on every jade order, including samples. That single change prevents the most common dispute pattern, where the buyer tries to renegotiate after receiving goods because the original PO was ambiguous. It also makes supplier qualification faster, because vendors who cannot comply will self-select out early.

Jadeite vs Nephrite: The Only Differences That Matter to Buyers

You do not need a museum-level mineral lecture to buy correctly. You need a buyer-level model of what the materials are, why visual identification fails, and which physical differences affect yield, pricing, and durability.

What They Are (Mineral Identity in One Minute)

Jadeite is a pyroxene mineral, and it is distinct from nephrite, which is an amphibole aggregate commonly associated with the tremolite–actinolite series. GIA’s foundational jade references emphasize that jadeite is “very different from nephrite” in chemistry and internal structure, which is the core reason the trade name “jade” creates procurement ambiguity.

For procurement, the practical takeaway is simple. Identity is not a “nice-to-have” detail, because it sits upstream of how the stone behaves in manufacturing, how the market prices it, and how labs verify it.

Why Visual ID Breaks at Scale (Photos, Lighting, Finishing Tricks)

Visual identification fails in B2B workflows because it is sensitive to lighting, polish style, camera white balance, and post-processing. It also breaks when suppliers mix lots, because buyers often judge from a few “hero” photos that are not representative of production. Even honest suppliers can deliver drift if the lot is not controlled, because natural stone variation is real and non-linear.

This is why your workflow must be documentation-driven. The buyer’s job is not to “be right by eyesight,” but to create a system where the supplier has incentives to label lots correctly, and where disputes can be resolved quickly with agreed methods.

Property Differences That Change Order Outcomes

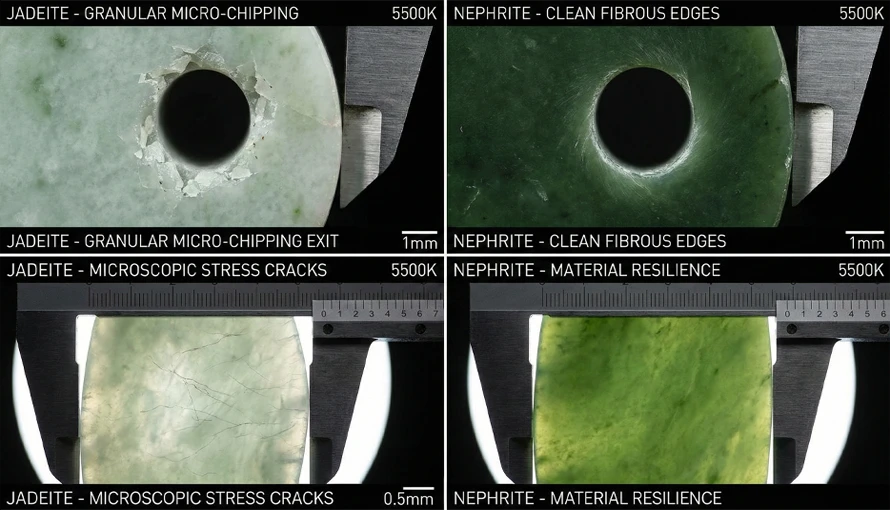

The biggest buyer mistake is assuming one mechanical property tells the whole story. Hardness and toughness are not the same thing, and confusing them leads to wrong material choice for thin designs, bangles, and high-stress wear items.

Jadeite and nephrite can differ in how they respond to stress and edge impacts, which can show up as different chipping rates during carving, setting, and shipping. That is why design tolerances, minimum thickness guidance, and edge radius rules should be written with the chosen material in mind. Your procurement spec should treat “identity” as a design constraint, not just a label.

Procurement Implications: Pricing, Lot Risk, Lead Time, and Forecasting

Once identity is locked, you can finally talk about money and timelines in a way that is comparable across suppliers. Before identity is locked, pricing conversations often turn into “apples to oranges,” because the word “jade” hides the real drivers of value and yield.

Why Price Comparisons Fail Without Identity + Treatment + Grade Definitions

Jadeite and nephrite can carry different market dynamics, and value can change dramatically with subtle differences in quality factors. For example, GIA notes that with top-quality “imperial” jadeite, small size differences can cause large value differences, while nephrite often does not scale in value the same way with size.

If your RFQ does not define identity, treatment, and a grade logic, you are effectively letting suppliers quote different products under the same name. That invites the most expensive kind of mistake: selecting a supplier based on a lower quote that was never comparable.

Lot-to-Lot Risk: What Actually Drifts

Lot drift is not only color drift. It includes translucency shifts, inclusion rate changes, micro-fracture prevalence, and polish behavior, which can affect both scrap rate and customer perception.

You reduce drift by treating the lot as the product. That means every box needs a lot ID, every lot needs representative photos, and every lot needs a retained reference sample that both sides agree represents the approved target.

How to Reduce Supply Risk Without Inflating MOQ

A scalable strategy is a three-step commitment. First, approve a pilot lot and produce a small run that establishes real yield and finish behavior. Second, lock a reference sample set (including “acceptable defect” examples) and write tolerances around it. Third, scale production only after the supplier demonstrates repeatability under the same process and the same material-lot control.

This approach protects buyers who are building SKUs over time. It also protects suppliers, because it reduces subjective rejections that occur when the buyer’s expectations were never written down.

Verification Workflow: From Receiving Checks to Lab Proof (Cost-Optimized)

Verification is where many buyers overcorrect. Some buyers do nothing and trust photos, while others demand expensive lab proof for every shipment and slow down their supply chain. The right approach is a tiered workflow that scales cost with risk.

Level 1: Receiving Inspection (Screening, Not Proof)

Receiving inspection should be designed to catch obvious inconsistencies and protect you from “lot mixing” and “substitution.” It should include lot ID checks, weight/size conformity checks, and magnification-based defect screening that matches your defect dictionary. It should also include photo documentation of incoming goods under consistent lighting so disputes are fact-based.

This level does not prove mineral identity conclusively. It creates the evidence trail that makes higher-level verification meaningful when you need it.

Level 2: Instrument Testing (When to Escalate)

When the order value is high, when your brand claims are strict, or when a supplier is new, you escalate. Raman spectroscopy is widely used to differentiate jadeite and nephrite because their spectra have characteristic differences, and application notes and studies show they are “easily differentiated” by Raman features. (TSI)

For treatment detection, buyers should understand one key point: polymer impregnation in jadeite is not reliably detected by “just looking.” GIA’s research on bleached and polymer-impregnated jadeite states that infrared spectroscopy provided conclusive evidence of polymer impregnation across cases studied, which is why FTIR often appears in serious treatment workflows.

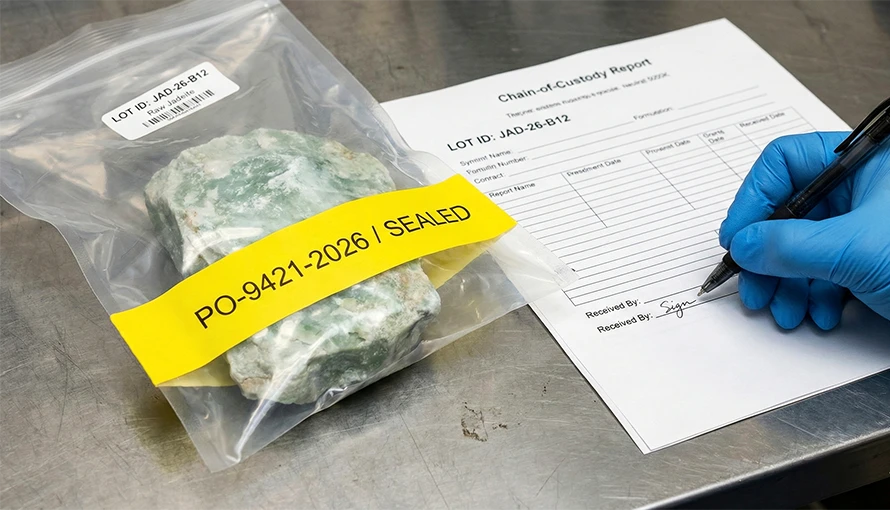

Level 3: Documentation & Chain-of-Custody (Make Reports Enforceable)

Testing only helps procurement if the report can be tied to the delivered goods. That is why the sample for testing should be sealed, labeled with lot ID and PO number, and documented with photographs and signatures. Chain-of-custody procedures prevent the “wrong sample” problem that makes disputes impossible to resolve.

Treatment & Disclosure: Where Most Disputes Actually Start

Identity solves only one half of the problem. The other half is treatment, because treatment can change value, durability over time, and what your marketing team can safely claim.

Treatments That Change Value and Claim Risk

Jadeite in particular is frequently treated in the market, including bleaching, dyeing, polymer impregnation, or combinations. GIA’s gem trade notes highlight that treatment options for jadeite are numerous, and polymer impregnation is a common approach that may not be easy to observe by magnification.

From a procurement standpoint, the issue is disclosure and enforceability. If a supplier says “natural” without defining what that means, you are inviting downstream customer complaints and compliance issues when treatments are later discovered.

How to Specify Treatment Without Becoming a Gemologist

You can write a treatment requirement in business language. Require that the supplier discloses any treatments and agrees to a verification method for high-risk SKUs or random audits, and then define remedies if disclosure is false.

If you need one technical anchor, use FTIR as a common escalation method for polymer impregnation, because GIA’s research identifies infrared spectroscopy as conclusive for polymer impregnation detection in the context of their study. That does not mean FTIR solves every treatment question, but it gives procurement an enforceable, widely recognized reference point.

Claim-Safe Language for Listings (Avoiding Downstream Issues)

Procurement should not write marketing copy, but it must create guardrails. Your PO and supplier documentation determine what your product pages can safely claim, because the brand is responsible for accuracy even if a supplier misled you.

A simple internal rule works well. If the supplier cannot provide disclosure and verification options you trust, your listing language should remain conservative and avoid absolute claims that imply untreated status or rarity.

Copy/Paste Purchase Spec Template: What to Put on Your PO

A PO spec should be enforceable, auditable, and scalable. It should also be readable by suppliers, because unclear specs create mistakes that get blamed on “stone variability” even when the real issue was missing definitions.

Non-Negotiables: Identity, Treatment, Traceability

Include a mandatory identity line item. It should state “Jadeite (pyroxene) / Nephrite (amphibole aggregate)” and require the supplier to label lots accordingly, with lot IDs printed on packaging and invoices.

Include a mandatory treatment line item. It should require written disclosure of any bleaching, dyeing, polymer impregnation, or other enhancements, and it should specify the audit method for high-risk SKUs or random sampling.

Include a mandatory traceability line item. It should require retained reference samples, incoming lot photos, and document retention tied to your PO number.

Copy/Paste Text (PO Section):

“Material Identity: Supplier warrants the delivered material is [Jadeite / Nephrite] as specified, and will provide lot IDs on all packaging and invoices. Treatment Disclosure: Supplier must disclose any treatments (including bleaching, dyeing, polymer impregnation, or combinations) in writing before production. Traceability: Supplier must maintain lot segregation and provide representative lot photos; Buyer may request verification testing on retained samples tied to lot ID and PO number.”

Quality Parameters That Don’t Collapse in Disputes

Define color range with reference photos, not adjectives alone. “Apple green” and “icy” mean different things to different teams, and suppliers can exploit that ambiguity.

Define translucency with a simple measurable proxy if you can, such as a standardized backlight photo method with fixed distance and exposure settings. Define defect terms in a “defect dictionary” that includes photos of cracks, pits, black spots, cottony inclusions, and polish haze, because written words alone invite disagreement.

Dimensional & Finish Specs (For Carved/CNC Items)

For carved and CNC-produced parts, tolerances must be written like manufacturing tolerances. State minimum thickness, hole diameter tolerance, edge radius, and polish level, and define inspection tools or methods.

This is where Jade Mago’s manufacturing strengths become a procurement advantage. Precision carving and consistent QC reduce variability, but only if the buyer’s spec is explicit enough to measure against.

[Insert: Factory Visual] Caliper measurements, gauge checks, and a polishing QC station photo to make the “measurable spec” concept concrete.

Contract & Dispute Prevention: Turn Specs into Enforceable Terms

Specs define what you want. Contracts define what happens when you do not get it, and that is where you prevent expensive arguments.

Material Identity Warranty + Remedy Logic

Your contract should include a warranty that the material identity matches the PO, and it should define remedies. Remedies should include replacement, refund, or credit terms, and it should define who pays shipping when identity is wrong.

This clause matters because identity is foundational. If identity is wrong, discussing “grade” is irrelevant, and the contract should reflect that logic.

Acceptance Window + Inspection Method

Define an inspection window that starts on delivery date. Define how rejects must be documented (photos, measurements, lot ID, defect category), and define how the supplier will respond.

This prevents the two most common disputes. One is “you waited too long,” and the other is “your rejection is subjective,” both of which disappear when process is written down.

Reference Sample Clause (Best ROI Clause)

Include a clause requiring production to match an approved reference sample within defined tolerances. A reference sample is a shared truth, which is why it reduces disputes more than almost any other term.

Copy/Paste Text (Clause Snippet):

“Reference Sample: Buyer and Supplier agree on reference samples for color range, translucency, finish, and defect thresholds. Production lots must match reference samples within the tolerances documented in the PO. Deviations beyond tolerance constitute nonconformance and trigger the remedy terms.”

Supplier Qualification: 12 Questions That Surface Risk Before Deposit

Contracts help, but the cheapest dispute is the one you never create. Supplier qualification is where you identify whether a vendor can run an identity-and-treatment-controlled workflow, or whether they operate on informal trade language.

The 12 Questions (Identity, Treatment, Lot Control, Returns)

Ask how the supplier distinguishes jadeite vs nephrite and whether they can support Raman/FTIR escalation when required. Ask whether they segregate lots with IDs and whether they can provide representative photos of the exact lot used for your order.

Ask how they disclose treatments, and whether they have a standard disclosure form. Ask what their return and remake policy is when identity or treatment disclosure is wrong, and whether they accept third-party verification results tied to chain-of-custody.

Red Flags (Neutral, Professional, Non-Accusatory)

A red flag is not “they don’t have a lab in-house.” A red flag is that they refuse to label lots, refuse to disclose treatments in writing, or will not agree to a verification workflow for high-risk SKUs.

Another red flag is inconsistent language. If a supplier changes definitions depending on the negotiation, you should expect that ambiguity to reappear during disputes.

How Jade Mago Executes This System (Process Transparency)

You should choose partners who can execute the system, not just promise it. At Jade Mago, the goal is to turn material identity and treatment requirements into a repeatable production workflow that supports cross-border procurement teams.

Incoming Inspection → Sample Approval → Production → Final QC

Incoming inspection focuses on lot segregation, labeling, and documentation. Sample approval locks the reference sample and the measurable acceptance criteria. Production follows the locked spec, and final QC verifies dimensions, finish, and defect thresholds before packing.

This workflow is designed to reduce surprises for product managers and procurement leads. It also reduces churn for suppliers, because clear specs and reference samples prevent subjective rejections.

What We Can Document for Your Team

We can document lot labeling, incoming inspection photos, in-process QC checks, and final inspection results. We can also coordinate third-party verification workflows when your SKU value or brand claims justify escalation.

Documentation is not “extra paperwork.” It is the mechanism that makes your PO enforceable and reduces the total cost of ownership across repeat orders.

CTA: Send CAD + Target Specs → Get a Risk-Checked Quotation

If you send your CAD files, target dimensions, finish requirements, and your identity/treatment requirements, we can respond with a quotation that includes risk flags. We will also recommend minimum thickness and tolerance choices that reduce breakage risk for the selected material identity.

[Insert: RFQ Form Fields] Material identity, treatment requirement, reference sample process, tolerance targets, finish targets, annual volume forecast, and verification escalation preferences.

Quick Reference: Jadeite vs Nephrite Procurement Snapshot

| Topic | Jadeite | Nephrite | Why Procurement Cares |

|---|---|---|---|

| “Jade” meaning | One of the minerals called “jade” | One of the minerals called “jade” | PO must specify identity to avoid ambiguity. |

| Verification (identity) | Raman can differentiate | Raman can differentiate | Define escalation triggers to control cost. |

| Treatment risk (trade) | Frequently treated; polymer impregnation exists | Also can be treated but market focus often differs | Must require disclosure + audit method. |

| Polymer detection | FTIR is key evidence method in GIA study | FTIR/Raman used in studies for characterization | Tie testing to lot IDs + chain-of-custody |

FAQ

Can a supplier legally label nephrite as jade?

“Jade” can be used generically, but if your product listing or internal SKU claims “jadeite,” delivering nephrite becomes a misrepresentation against your spec. The practical procurement move is to write “Jadeite (pyroxene)” or “Nephrite (amphibole aggregate)” explicitly in the PO and contract so there’s no ambiguity.

What’s the fastest reliable way to distinguish jadeite from nephrite at scale?

For scalable verification, Raman spectroscopy is widely used because jadeite and nephrite show characteristic spectral differences and can be differentiated with Raman features in gem testing contexts. Use it as an escalation step when order value or brand claims justify the cost.

Is visual inspection (color, translucency, “oily” look) enough to confirm identity?

Not for procurement decisions. Visual cues can be influenced by lighting, polish style, and photo processing, and overlap exists between jadeite and nephrite appearances. Treat visual checks as screening, then rely on workflow + documentation and escalate to testing when needed.

What does “A/B/C jade” mean, and why should buyers care?

In trade practice, these labels are used to communicate treatment status (with “B” commonly associated with bleaching and polymer impregnation, and “C” commonly linked to dyeing). Buyers should require written disclosure and define what treatments are acceptable for the SKU and claims.

f my supplier says “natural jade,” what should I request in writing?

Ask them to define “natural” operationally in the PO:

1、Material identity (jadeite vs nephrite)

2、Treatment disclosure (what was/wasn’t done)

3、Lot traceability (lot ID + representative photos + retained reference sample)Then specify audit rights (random sampling and agreed testing method for high-risk SKUs).1

-900x375.webp)