Introduction

The global manufacturing landscape is undergoing a profound shift, moving away from a “production-at-all-costs” mentality toward a framework that values environmental health, social equity, and transparent governance. In the jade processing industry—a sector traditionally defined by ancient techniques and intensive manual labor—this transformation is not just a trend but a necessity for survival in the modern B2B market. At JADE MAGO, we have observed that international buyers are no longer just asking about the price per unit or the lead time of a shipment. Instead, they are increasingly concerned with the “Green Credentials” of their supply chain partners.

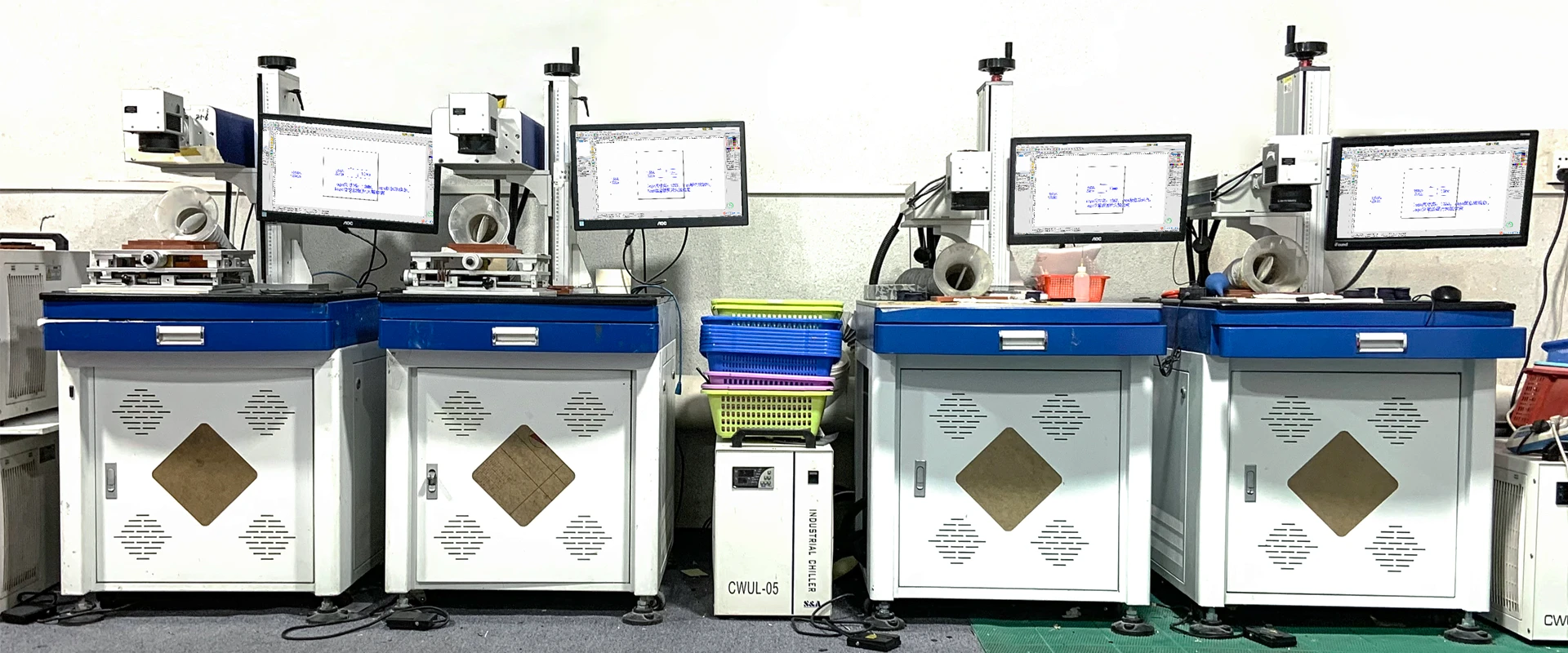

Laser engraving has emerged as the cornerstone of this “Green Processing” revolution. By replacing traditional abrasive methods with high-precision light energy, the jade industry is finally able to align itself with global Environmental, Social, and Governance (ESG) standards. This article will explore why the adoption of laser technology is the single most important step for a jade processing factory aiming to achieve ESG transformation. We will dive deep into how this technology reduces waste, protects workers, and creates a transparent, data-driven manufacturing environment that meets the rigorous demands of the 21st-century luxury and gift markets.

Table of Contents

The Dawn of a New Era: ESG in the Jade World

For decades, the jade industry operated under the radar of global sustainability discussions because it was viewed as a niche, artisanal craft. However, as jade products—ranging from wellness tools like Gua Sha boards to high-end jewelry—become staples in the global market, the environmental footprint of their production has come under intense scrutiny. ESG is no longer a buzzword reserved for Fortune 500 companies; it is a framework that defines the “bankability” and “reputation” of manufacturing firms like ours.

Defining ESG for Gemstone Manufacturing

In our specific context, Environmental (E) refers to the conservation of water and the reduction of mineral waste during the carving process. Social (S) focuses on the health of the artisans, ensuring that the dust and noise traditionally associated with jade workshops are eliminated. Governance (G) involves the digital tracking of production, ensuring that every piece of jade can be traced back to its origin and that the manufacturing process is ethically documented.

The Shift from Abrasives to Light

The traditional method of jade processing involves physical contact between an abrasive tool—often coated with diamond grit—and the stone. This process requires constant water cooling and produces significant amounts of slurry, which is difficult to dispose of without harming local ecosystems. Laser engraving changes this dynamic entirely by using a non-contact method. This shift represents the technological foundation of our ESG transformation, moving from mechanical destruction to thermal precision.

Environmental Stewardship: How Lasers Reduce Ecological Impact

The “E” in ESG is perhaps the most visible area where laser engraving provides an immediate benefit. Traditional jade carving is an “extractive” and “dirty” process that consumes vast amounts of natural resources. By integrating laser systems, JADE MAGO and other industry leaders are able to drastically lower the carbon and water footprint of every product manufactured.

Eliminating Water Waste in the Workshop

In a conventional CNC or manual jade workshop, water is used as a coolant and a dust suppressant. This water becomes contaminated with fine jade particles and chemical coolants, often ending up in local water systems if not treated properly. According to the United Nations Sustainable Development Goal 6, ensuring sustainable management of water is critical for global health. Laser engraving is a dry process; it uses a focused beam of light to vaporize or fracture the surface of the jade on a microscopic level. Because there is no physical friction, there is no heat buildup that requires a liquid coolant, effectively reducing the facility’s water consumption by up to 90%.

Reducing Material Waste through Precision

Traditional carving tools have a “kerf” or a thickness that results in a certain amount of material being turned into dust. When working with precious materials like natural Nephrite or Jadeite, every milligram of waste represents a loss of natural resources. Laser engraving operates with a beam diameter often smaller than 0.1mm, allowing for incredible detail without the bulk removal of material. This precision ensures that we maximize the yield from every raw stone slab, adhering to the principles of a Circular Economy by minimizing the “Jade Tailings” that would otherwise end up in landfills.

Energy Efficiency and Carbon Footprint

While it might seem that a high-tech laser would consume more power than a simple hand tool, the reality is the opposite when viewed at scale. Modern fiber and CO2 lasers are incredibly efficient, converting a high percentage of electrical energy into light energy. Because the process is much faster than manual carving—often completing in seconds what would take a human hours—the total energy consumed per unit is significantly lower. This reduction in energy use directly translates to a lower carbon footprint, a key metric for any brand looking to report its ESG progress to stakeholders.

Social Responsibility: Protecting the Human Capital in Jade Workshops

The “S” in ESG stands for Social, and in the context of jade manufacturing, it primarily concerns the health, safety, and well-being of the workforce. For centuries, jade carving has been a high-risk profession. The traditional methods of grinding and polishing stone create fine mineral dust that poses significant long-term health risks to artisans. By adopting laser engraving, JADE MAGO is not just improving efficiency; we are fundamentally changing the working conditions for thousands of people in the industry.

Combating Silicosis and Respiratory Hazards

One of the most significant health challenges in the gemstone industry is silicosis, a lung disease caused by inhaling crystalline silica dust. Traditional dry-grinding or even wet-carving without adequate ventilation can lead to workers inhaling microscopic particles that scar lung tissue. According to reports by the World Health Organization (WHO), workplace exposure to mineral dust is a leading cause of preventable respiratory illness. Laser engraving systems are typically enclosed units equipped with high-efficiency particulate air (HEPA) filtration and exhaust systems. This setup captures vaporized particles at the source, ensuring that the air in the workshop remains clean and safe for the operators.

Enhancing Ergonomics and Reducing Physical Strain

Manual jade carving requires hours of intense focus and repetitive physical motion, often leading to musculoskeletal disorders and chronic eye strain. The precision required to hold a vibrating tool against a hard stone like jadeite for an entire shift takes a massive toll on the human body. Laser technology shifts the artisan’s role from high-strain physical labor to technical supervision and design. Instead of hunching over a workbench, the modern jade technician operates a computer interface, overseeing the laser’s progress from a comfortable distance. This transition allows for a more inclusive workforce, extending the careers of master carvers who may no longer have the steady hands of their youth but possess invaluable design expertise.

The Evolution of Craftsmanship and Skill Sets

There is a common misconception that automation replaces the artisan. In reality, laser engraving acts as a powerful tool that augments human creativity. At JADE MAGO, we view the “Social” aspect of ESG as an opportunity to upskill our team. By learning to operate advanced laser systems and CAD (Computer-Aided Design) software, our workers transition from traditional laborers to high-tech manufacturing specialists. This shift increases their value in the global job market and ensures that the ancient art of jade carving remains relevant in the digital age. We are preserving the cultural heritage of jade while equipping the next generation with the tools of the future.

Governance and Transparency: Building Trust through Digital Precision

The “G” in ESG—Governance—is often the most overlooked component in the jade industry, yet it is vital for B2B relationships. Governance refers to how a company is managed, the transparency of its operations, and the ethical standards it upholds. In an industry often plagued by “gray market” stones and questionable origins, laser technology provides a digital ledger of truth.

Digital Traceability and Anti-Counterfeiting

One of the greatest challenges for jade buyers is verifying the authenticity and the journey of the stone. Laser engraving allows us to etch microscopic, indelible serial numbers or QR codes directly onto the jade, often in areas that do not interfere with the aesthetic design. These “Digital Birth Certificates” can link a physical piece of jade to a database containing its origin, the date of manufacture, and the specific ESG metrics achieved during its production. This level of transparency is essential for brands that want to comply with the OECD Due Diligence Guidance for responsible mineral supply chains.

Standardization in a Fragmented Market

Historically, the quality of jade carving was subjective, depending entirely on the individual skill of the carver on a particular day. This inconsistency makes it difficult for B2B clients to maintain brand standards across thousands of units. Laser engraving introduces a level of governance through standardization. Once a design is approved, the laser executes it with 100% fidelity every single time. This consistency reduces the “governance risk” for our clients, ensuring that they receive exactly what they ordered without the variations and defects that often lead to disputes and waste.

Ethical Documentation and Auditing

For a company to claim ESG compliance, it must be able to provide data. Unlike manual processes, laser engraving machines are integrated with software that tracks every minute of operation, every watt of energy used, and every unit produced. This creates a “data trail” that can be audited by third-party ESG rating agencies. When a client asks for proof of our green processing claims, we don’t just provide marketing slogans; we provide raw data exported from our manufacturing systems. This level of corporate governance builds deep trust with international luxury groups who have their own strict ESG reporting requirements.

Technical Comparison: Why Lasers Outperform Traditional CNC and Manual Methods

To fully appreciate why laser engraving is the “Key” to this transformation, we must look at the technical limitations of previous generations of technology. While CNC (Computer Numerical Control) machines were a major step forward from hand-carving, they still rely on physical contact and mechanical force, which limits their ESG potential.

Contact vs. Non-Contact Processing

Traditional CNC machines use diamond-tipped bits that physically grind away the stone. This creates heat, vibration, and noise pollution—all of which are detrimental to the workshop environment. Furthermore, bits wear down and must be replaced frequently, creating a secondary waste stream of spent industrial diamonds and metal. Laser engraving is a non-contact process. There are no “consumables” like drill bits to throw away. The “tool” is a beam of light that never gets dull. This significantly reduces the overhead costs and the environmental impact of maintaining a tool inventory.

Complexity and Fine Detail Capability

Jade is incredibly tough, which makes it difficult to carve fine details using mechanical tools. To achieve high levels of detail, a manual carver must use extremely small, fragile bits that break easily. A laser beam, however, can be focused to a diameter of mere microns. This allows for the creation of intricate textures, photographic-quality engravings, and complex geometric patterns that are simply impossible with mechanical tools. For the jewelry industry, this opens up new design possibilities that were previously discarded due to technical limitations, allowing for more creative use of smaller, high-quality jade fragments.

Economic Viability: The ROI of Sustainable Jade Manufacturing

A common hurdle for many traditional factories is the initial capital expenditure required for high-end laser systems. However, when we look at the lifecycle of the technology, the economic benefits of laser engraving become undeniable. In the world of ESG, we often talk about “Future-Proofing”—ensuring that a business remains competitive as regulations tighten and consumer preferences shift toward ethically produced goods.

Efficiency and Speed-to-Market

In the traditional B2B gemstone trade, lead times are often measured in weeks or even months because of the manual labor involved in carving and detailing. Laser engraving operates at speeds that mechanical tools cannot match. A design that takes a master carver three days to etch can be completed by a precision laser in under thirty minutes with higher consistency. This increased throughput allows brands to respond to market trends in real-time, reducing the need for massive inventories and the associated waste of overproduction. By streamlining the “Design-to-Delivery” pipeline, we are practicing an economic form of sustainability that minimizes resource idling.

The “Green Premium” and Market Access

The global luxury market is increasingly dominated by Gen Z and Millennial consumers who prioritize environmental and social values. According to studies by Bain & Company on the Luxury Market, sustainability is now a top-three factor in purchasing decisions. By positioning jade products as “Laser-Processed & Eco-Friendly,” brands can command a “Green Premium.” Furthermore, many high-end retailers in Europe and North America now require ESG compliance documentation before they will even list a supplier. Laser engraving provides the technological credentials needed to bypass these barriers to entry, providing JADE MAGO’s clients with a significant competitive advantage.

Reduced Consumables and Maintenance Costs

As mentioned previously, the absence of physical contact means there are no drill bits, grinding wheels, or polishing compounds to constantly repurchase. Over a five-year period, the savings on these industrial consumables can often pay for the laser machine itself. Additionally, the maintenance of a laser system is primarily electronic and optical, rather than mechanical. There are fewer moving parts to break and no slurry-filled pumps to clog. This reliability ensures that the factory can maintain a “Zero-Downtime” schedule, which is crucial for meeting the high-volume demands of global B2B partnerships.

The Science of Light on Stone: Understanding Material Reactions

From my years in the workshop, I know that “Jade” is an umbrella term for two distinct minerals: Nephrite and Jadeite. Each reacts differently to laser energy, and understanding this science is critical for achieving a high-quality, sustainable finish without damaging the integrity of the stone.

Nephrite: The Interlocking Fiber Structure

Nephrite is known for its extreme toughness due to its interlocking fibrous structure. Traditional tools often struggle with Nephrite because the fibers can cause the tool to “skip” or create micro-fractures. Laser engraving, however, interacts with the stone at a molecular level. The laser’s heat causes a localized vaporization of the fibers, creating a clean, dark-etched line that contrasts beautifully with the stone’s natural color. This process is entirely controlled, ensuring that the structural integrity of the jade is never compromised, which is a key requirement for items like “Gua Sha” tools that must remain smooth and durable.

Jadeite: The Crystalline Challenge

Jadeite is more brittle and has a more crystalline structure than Nephrite. It requires a different laser frequency—often a UV laser or a high-frequency fiber laser—to prevent the stone from “spalling” or chipping. At JADE MAGO, we use precise “Cold Processing” laser techniques for high-end Jadeite. This method uses short pulses of light that are so fast the heat doesn’t have time to spread to the surrounding crystals. This level of technical control is what allows us to produce high-definition imagery on Jadeite jewelry without the risk of thermal shock, a common problem in older, less sophisticated factories.

Color Transformation and Surface Integrity

One of the most fascinating aspects of laser engraving in the jade industry is the ability to create different visual effects without using chemical dyes or inks. Depending on the power settings, a laser can create a frosted white effect, a deep charcoal etch, or even a subtle “watermark” style finish. This eliminates the need for potentially toxic coloring agents that are often used in traditional “B-Grade” or “C-Grade” jade treatments. By using light alone to alter the surface, we ensure that the final product remains “100% Natural” and “Non-Toxic,” adhering to the highest standards of the Consumer Product Safety Commission (CPSC).

Design Innovation: Pushing the Boundaries of “Quiet Luxury”

The aesthetic of the jade industry is evolving. We are moving away from the overly ornate, heavily carved styles of the past toward a “Quiet Luxury” and “Artisan Atelier” feel. This shift is perfectly aligned with the capabilities of laser technology, which excels at minimalism and precision.

The “Documentary × Aesthetic” Style

In our content and product design, we often aim for a style we call “Documentary × Aesthetic.” This involves capturing the raw, natural beauty of the jade while applying precise, modern geometric patterns via laser. This style tells a story—the story of a natural mineral shaped by human ingenuity and light. B2B clients looking to build a brand identity around “Modern Tradition” find that laser-engraved jade pieces offer a unique narrative that resonates with modern consumers. It looks intentional, sophisticated, and, most importantly, clean.

Customization for Small-Batch Collections

The digital nature of laser engraving makes it the perfect tool for the “Small-Batch Wholesale” model. Traditional mold-based or hand-carved methods require large minimum order quantities (MOQs) to be cost-effective. With a laser, we can change the design in seconds just by uploading a new file. This allows our clients to test small collections of 50 or 100 units with different laser-etched patterns or logos before committing to a larger production run. This flexibility reduces the risk of unsold inventory, which is a major contributor to waste in the fashion and jewelry sectors.

Conclusion

The transformation of the jade industry through ESG principles is not an overnight process, but it is an inevitable one. At JADE MAGO, we have seen firsthand how the integration of laser engraving technology can bridge the gap between ancient stone and modern values. By focusing on Sustainable Jade Laser Engraving, we are addressing the environmental concerns of water and waste, the social concerns of worker health and safety, and the governance concerns of transparency and data-driven manufacturing.

As we look toward the future, we see a jade industry that is cleaner, safer, and more innovative. We believe that the brands that embrace these “Green Processing” techniques today will be the leaders of the global market tomorrow. Our commitment to ESG is not just about compliance; it is about honoring the natural beauty of the jade by ensuring that the way we process it is as pure as the stone itself. We invite our partners and fellow manufacturers to join us in this light-driven revolution, ensuring that jade remains a symbol of beauty, status, and sustainability for generations to come.

Frequently Asked Questions

How does JADE MAGO use laser technology for brand authentication and traceability?

In an industry where authenticity is paramount, laser technology provides an indelible way to track and verify every piece of jade. We can etch microscopic QR codes or unique serial numbers into the stone that are invisible to the naked eye but easily scanned for verification. This “Digital Birth Certificate” links the physical product to its ethical origins and manufacturing data, helping brands comply with international transparency regulations. Such high standards of governance build immense trust with luxury retailers who must prove the integrity of their entire supply chain to sophisticated consumers.

Why is laser engraving more cost-effective for small-batch or custom orders?

Traditional jade manufacturing often requires the creation of expensive molds or high labor costs for even the simplest custom designs, which forces brands to place large minimum orders. Because laser engraving is a purely digital process, changing a design is as simple as uploading a new file to the system. This flexibility allows JADE MAGO to offer small-batch wholesale services that are economically viable for niche collections or localized market tests. By reducing the need for large, risky inventories, our B2B clients can practice a more sustainable business model that minimizes overproduction and waste.

Can laser technology really minimize material waste in high-value stones?

When processing precious materials like natural Nephrite or Jadeite, every millimeter of stone counts toward the final yield and economic value. Traditional mechanical tools have a significant “kerf” or cutting width, which turns a portion of the stone into unusable dust. In contrast, the precision of a laser beam—often smaller than 0.1mm—allows for incredibly tight tolerances and intricate designs that maximize the usage of the raw material. This high-efficiency approach supports the principles of a circular economy by ensuring that more of the natural resource ends up in the final product rather than on the workshop floor.

-900x375.webp)