Introduction

Manufacturing Nephrite and Jadeite has always been a challenge due to its tough surface material. Artisans and factories alike relied on friction-based methods like wire saws with diamond-tipped circular blades or friction milling to divide boulders into workable slabs for manufacturing purposes. While effective, these traditional processes produce heat, waste material due to wide cutting paths, and can induce mechanical stress which fractures high-value stone products.

JADE MAGO has witnessed an industry shift toward Abrasive Waterjet Machining (AWJM). No longer just used for metal and glass processing, this cutting method has become the go-to standard in high-end gemstone production. Waterjet cutting utilizes a supersonic stream of water mixed with abrasive particles to erode material rather than grind it; business owners and factory managers must understand that this represents a transition from brute force to fluid precision.

In this comprehensive guide, we will break down the technical barriers associated with waterjet cutting technology. We will explore why waterjet cutting increases material yield while simultaneously protecting jade’s structural integrity, and why it is an optimal choice for complex geometric cuts. Regardless of whether you are purchasing OEM products or setting up your own processing line, understanding this workflow is vital for making sound business decisions.

Table of Contents

The Physics of Cold Cutting Technology

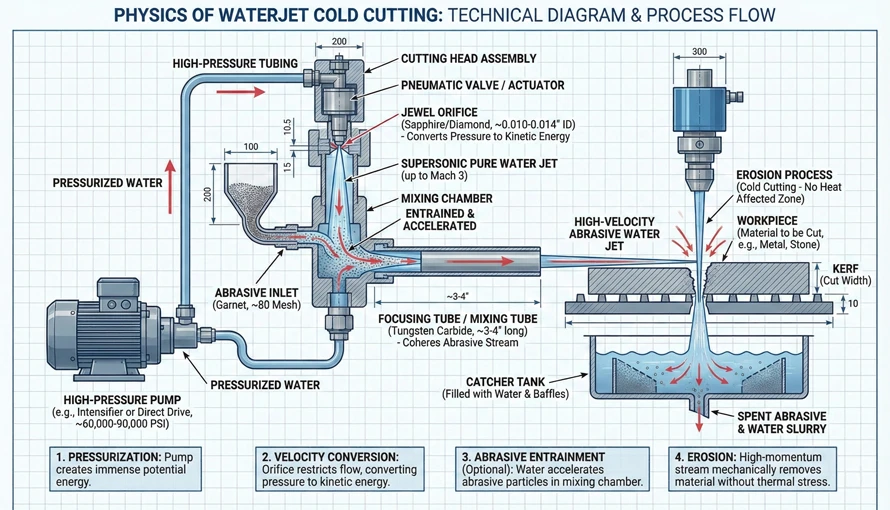

To understand why waterjet cutting is our go-to technology at JADE MAGO, one must look closely at how the cut happens. While lasers or saws burn and grind materials away, waterjets use supersonic erosion for cutting.

Hydro-Abrasive Power Hydro-Abrasive Power relies heavily on water’s acceleration. A high-pressure pump pressurizes it to levels often exceeding 60,000 PSI (4,100 bar), and then it passes through a tiny orifice made of diamond or sapphire to form a focused beam – however this may not be sufficient to cut dense Nephrite or Jadeite efficiently without additional materials such as grinding particles of steel into powder form first.

The magic happens in the mixing chamber. Here, abrasive material–usually alluvial garnet–is added to a water stream and rapidly accelerated to speeds approaching Mach 3. When this stream hits jade, each grain of garnet acts like a microcutter that removes material granularly. This allows this machine to slice through boulders of various densities without stopping or stalling; an issue often associated with mechanical saws.

Eliminate Thermal Stress in Gemstones

One of the greatest advantages of AWJM in our industry is its cold cutting capability. Jade is a metamorphic rock composed of interlocking mineral fibers; when cut with traditional diamond saws, frictional heat generates intense localized heating effects which cause extensive stress to gemstones.

Industry Note: Rapid temperature changes (thermal shock) can result in micro-cracks to develop within jade, even though they may not be visible immediately; over time these could lead to product failure when polishing or wearing.

Waterjet cutting provides an inherently cool cutting environment, using water both as the carrier for the abrasives and coolant to preserve structural integrity of stone at its cut edges. For high-value rough stones such as Hetian jade or premium Jadeite, protecting their investment through eliminating heat-induced fractures is paramount in safeguarding against costly investments made in raw material.

For further reading on material hardness and its requirements for effective processing, referring to the Mohs Scale of Mineral Hardness can provide valuable insight. Jade typically ranks between 6.0-7.0 on this scale, necessitating harder abrasives than quartz in order to process effectively.

Implementing waterjet technology requires specific machinery. At JADE MAGO, we make sure our processing partners utilize equipment which combines power with extreme precision.

High-Pressure Pump Systems

Pumps are at the core of every waterjet system. In stone processing applications, we typically see two kinds of pumps: direct drive pump and intensifier pump.

Direct drive pumps work similarly to pressure washers but on a much larger scale. Utilizing a crankshaft with plungers for pressurizing water, direct drive pumps offer energy-efficiency as they have continuous flow capabilities – perfect for high volume factories where machines need to run continuously.

Intensifier pumps use hydraulic pressure to drive a piston and pressurize water, creating higher pressures – sometimes up to 90,000 PSI! Ideal for cutting thick or dense jade boulders at high cutting speeds while leaving behind cleaner edges requiring less secondary processing or polishing post production line.

Cutting Head and Abrasive Delivery

This component must be capable of withstanding internal abrasion of garnet stones while still offering precision in cutting operations.

Within the cutting head, a “mixing tube” or “nozzle” aligns water and abrasive. Its diameter determines the width of cut, known as “kerf”. Whenever possible in jade processing, we strive to minimize yield as much as possible by keeping our kerf as small as possible – for precision jewelry work this may mean using mixing tubes that measure as small as 0.76 mm!

Abrasive delivery systems must be calibrated precisely. Too much garnet feed into a stream can clog its nozzle; too little may reduce cutting power, leading to jade chips instead of smooth cuts. We usually employ 80-mesh garnet for general cutting applications, while for intricate carvings or thinner slabs a finer 120-mesh garnet offers smoother finishes that more closely resemble pre-polished states.

Digital Workflow and Design Integration

Today’s jade factory is more than a physical environment; its digital infrastructure comprises computer-aided design (CAD) and manufacturing (CAM), making JADE MAGO stand out as an scalable manufacturing brand.

Before any jade boulder is cut into individual slices, its shape and volumetric details must first be captured digitally using 3D scanning technology. We then create an accurate digital model of it so we can view its external dimensions within virtual reality space.

Designers use CAD software to layout cuts. This differs significantly from using markers on rocks; with software we can arrange our desired products–bangles, pendants or tiles–within its virtual boundaries of stone.

Nesting for Maximal Material Yield

Waterjet technology’s true financial advantage lies in “nesting,” the practice of placing parts as close together as possible to reduce waste.

Due to the waterjet beam being omnidirectional – meaning it can cut in any direction without rotating the stone–we can place parts within millimeters of each other. A traditional circular saw is limited to cutting straight lines; any curvier cuts require significant maneuvering which often creates “dead zones” of wasted material.

With waterjet software, we are able to easily rotate shapes and fit them together like pieces in a jigsaw puzzle. In an industry such as jade where raw material is sold by weight at exorbitant rates, an increase of 15% yield can create massive competitive advantage and translate directly to lower pricing for B2B clients.

Operational Benefits Over Traditional Sawing

For businesses considering alternative production methods, efficiency and versatility often determine their decision. Diamond wire saws and circular saws have long been industry standards; however Abrasive Waterjet Machining (AWJM) provides several distinct operational advantages that directly contribute to bottom line returns.

Unparalleled Geometric Freedom

One of the greatest restrictions of traditional sawing is linearity. Circular and wire saws are designed primarily for cutting straight lines; to produce curves like those needed in creating a bangle or carving preform, a craftsperson must often cut a square block and grind away excess material manually – an extremely time consuming and wasteful process.

Waterjet cutting frees manufacturing lines of geometric constraints by creating an omnidirectional tool path with waterjet cutting streams, making our machine capable of cutting intricate curves, sharp internal corners and complex organic shapes just as easily as straight lines. JADE MAGO uses this capability to produce “near-net-shape” blanks which closely resemble their final designs so subsequent grinding and polishing stages require far less labor and time than their non-cut versions would.

Waterjets’ unique operational feature is their internal piercing capability, while traditional saws must enter material from an edge. If you need to cut a hole in the center of a jade slab without cutting through its perimeter, saws cannot do this effectively – rather you would need to drill a pilot hole and thread wire saw through manually first; an inefficient process.

Waterjet technology enables “internal cutouts”, or nesting parts inside other parts, maximizing material usage from every square centimeter of raw stone material. For example, when we cut large jade rings using traditional processing, material from their core is typically wasted; with waterjet piercing we can turn that material into pendants or beads that maximize use from every centimeter of raw stone used.

Edge Quality and Secondary Processing

The quality of cut edges determines how much work remains for polishing teams to do in post-cutting processing. Diamond saws often leave “swarf” marks or deep scratches that require aggressive grinding to be removed, especially if the blade wandered or vibrated during cutting.For more information on surface finishes and roughness averages (Ra), manufacturing engineers often consult guides on Surface Metrology.

Navigating Technical Challenges

While AWJM excels in many respects, it still presents unique technical hurdles and limitations. At JADE MAGO we understand these restrictions are vitally important to ensuring successful implementation and quality control of any initiative.

Managing Stream Lag and Taper

A waterjet stream is not a rigid tool like metal drill bits; as the waterjet penetrates deeper into jade, its flow loses energy and bends slightly opposite of its direction of travel, known as “stream lag.” In addition, as it cuts deeper, its cuts widen at the top before narrowing towards its base creating a V-shaped edge known as taper.

Taper in high-precision applications such as inlay work with jade must fit perfectly into metal settings is unacceptable, which is why modern machines utilize “Dynamic Waterjet” technology or 5-axis cutting heads to address it. These advanced heads automatically tilt their nozzles to compensate for taper. By angling the stream, machines ensure that side remains perpendicular to surface; using dynamic heads like these ensure our tolerances stay tight (typically +/-0.1mm).

Piercing Fragile Materials Although piercing offers many advantages, it also presents potential dangers. When piercing high-pressure streams impact brittle stones like Nephrite or Quartz for the first time, an initial shockwave can cause it to shatter or laminate as though hit by a hammer directly at that spot.

To overcome this challenge, sophisticated software controls are essential. Our “low-pressure piercing” technique utilizes lower pressures initially in order to gently erode an entry hole before ramping up to full cutting pressure when necessary. For additional stress distribution and prevention against hydrostatic pressure cracking of stone surfaces we may employ “ramping.” In such instances the nozzle enters while moving instead of stationaryly piercing.

Abrasive Embedding and Staining

Light-colored stones like Hetian jade or jadeite present special challenges when cutting, including abrasive embedding. Sometimes the garnet particles used during cutting may become lodged within microscopic pores of its cut surface, leading to staining.

Environmental and Economic Sustainability

Modern manufacturing isn’t solely about speed; it must also take environmental considerations into account. While jade production traditionally generated dusty and noisy conditions, waterjet technology meets modern environmental standards which is increasingly essential to compliance and brand reputation management.

Traditional stone workshops are notorious for producing silica dust. Grinding and dry sawing operations release minute particles into the air that pose serious respiratory health risks (including Silicosis). To create an ideal working environment, dust-free environments should be prioritized in any workshop environment.

Waterjet cutting is an inherently wet process; cutting action occurs either under a thin film of water, or it is immediately suppressed by its stream itself, and all dust generated is captured at source before being funneled down to a collector tank below – producing clean factory floors and air that is safe to breathe. At JADE MAGO, protecting our technicians is of utmost importance – with this technology we ensure a compliant workplace for them all.

Closed-Loop Water Filtration

Water consumption is a significant concern with this technology; an average machine uses several gallons per minute. To address this, closed-loop filtration systems have been deployed.

Instead of draining cutting water directly into sewers, we opted to divert it through a settling tank where any heavy garnet sludge settles to the bottom and filter filtered before chilling to reduce pump heat emissions and recycle nearly all of it back to our machines. This approach allowed us to recycle nearly all the water used during production – not only reducing operational costs and environmental footprint but also providing renewable resource within the factory loop – thus decreasing operational expenses and conserving natural resources.

Diverse Application Scenarios: From Jewelry to Architecture

Waterjet technology allows JADE MAGO to expand their market presence into two separate sectors – fine jewelry and high-end architectural decor. While the fundamental technology remains the same, application strategies vary significantly based on end products produced.

Precision Manufacturing for Fine Jewelry

In fine jewelry manufacturing, every gram of material represents significant capital. Waterjet cutting’s primary objective should be material conservation and complex shaping rather than speed.

Making traditional jade bangles can be one of the most wasteful processes in our industry, using traditional core-drilling as the method. This often leaves an empty center space too small to hold large items. By switching to waterjet cutting instead, we are able to nest smaller bangles or pendants inside its inner diameter with minimal material loss – providing multiple high-value items from one slice of raw stone and increasing revenue generated per kilogram of material used.

Architectural Interiors At the other end of the spectrum lies architectural applications of jade. Luxury hotels and residences increasingly use it in wall features, backlight panels and floor inlays; projects that demand scale and consistency that manual carving cannot deliver.

Waterjet cutting allows for the mass production of jade tiles and mosaics with zero gap tolerances, eliminating grout lines altogether. We can cut intricate floral patterns or geometric shapes that fit together seamlessly without grout lines – this technique, often called “stone marquetry” or “pietra dura,” relies solely on precision of cut. Furthermore, since waterjet does not introduce heat or vibration into its process, jade slabs can be thinned down into veneers of only 3mm for backlit applications whereas traditional saws would likely shatter under vibrational stress.

To gain more insight into architectural stone applications, take a look at the Marble Institute of America (Natural Stone Institute). They have industry standards regarding installation and processing.

The Economic Analysis for B2B Partners

Whether jewelry brands or interior designers – understand the economics of waterjet processing to accurately price and plan projects. While hourly operational costs for waterjet machines tend to be higher than simple diamond saws, TCO per part can often be less.

Material Yield as the Primary Profit Driver

In the jade industry, raw material costs often outstrip labor and processing expenses. If a waterjet machine costs $100 an hour to operate but saves $500 worth of jade by optimizing nesting layout, its return on investment becomes almost immediately evident.

At JADE MAGO, we encourage our clients to view cost per usable gram rather than cutting hour. By employing software-driven nesting technology and cutting scrap rates significantly lower, resulting in reduced scrap rates for every pendant ordered – thus saving our clients money on raw stone purchases needed for production of 1,000 pendants with every 20 percent increase in material yield! These savings are passed directly back onto them making JADE MAGO an economical partner for large scale production runs.

Speed to Market and Rapid Prototyping

Time is an integral factor when considering economics: traditional mold making or setting up carving jigs typically take days or weeks; waterjet cutting does not require hard tooling – we simply import DXF/DWG files, set parameters accordingly, and begin processing immediately.

Future Trends in Stone Processing

At JADE MAGO, we remain aware of emerging technological innovations within stone processing. Waterjet industry advancements will further refine how we process jade.

Waterjet machines typically cut on two axes: X and Y axes). However, recent advancements such as 5-axis cutting heads are opening new avenues of cutting that enable beveled edges, chamfers, or complex 3D contours to be created more easily than before.

For jade processing, this means we can cut parts that have already been semi-shaped in three dimensions and reduce hand carving even further. Imagine cutting an already domed jade cabochon or bangle with an already rounded profile; although 3D waterjet cutting may currently be slower than 2D cutting technology is advancing quickly.

AI-Driven Material Analysis

Artificial Intelligence (AI)-driven stone processing is on the horizon, as we anticipate systems capable of scanning a raw jade boulder, identifying flaws or color zones using tomographic imaging, and automatically creating the optimal cutting layout to avoid cracks while maximising color retention. Such automation could transform jade processing from a traditional craft industry into an advanced high-tech manufacturing sector.

Conclusion:

The transition from traditional friction sawing to Abrasive Waterjet Machining (AWJM) represents a maturing of the jade industry, moving away from intuition and brute force towards data, precision and fluid dynamics.

JADE MAGO sees technology not as just another tool; rather it represents their philosophy of respect for material. By employing cold cutting technology to preserve natural structures of jade while advanced nesting software takes into account scarcity issues relating to resources; offering these capabilities to B2B partners has opened up a whole host of design possibilities that were once impossible or too expensive to attain.

No matter if it’s delicate jewelry components or large-scale architectural features that you need to produce, understanding the “how” is just as essential to success. Waterjet cutting provides the precision, yield, and safety required for modern manufacturing to thrive; we welcome you to make use of this cutting edge technology in your next project.

Frequently Asked Questions

Why is Waterjet Cutting considered safer for jade than traditional saws?

Traditional diamond saws generate intense friction heat, which causes “thermal shock” and can lead to micro-cracks in the stone. Waterjet Cutting is a “cold cutting” process. The water acts as both the carrier for the abrasive and a coolant, ensuring the structural integrity of the jade remains unaltered.

Can Waterjet Cutting handle complex shapes and internal cuts?

Yes. Unlike saws that are limited to straight lines, waterjets have unmatched geometric freedom and can cut intricate curves and organic shapes. It also features “internal piercing” capability, allowing the machine to start a cut in the center of the slab to create internal cutouts or nest smaller parts inside larger ones (e.g., cutting a pendant from the center of a bangle).

How does the machine prevent breaking fragile stones during the piercing process?

Piercing brittle stones like Nephrite or Quartz with high pressure can cause shattering. To solve this, we use a “low-pressure piercing” technique. The machine starts at a lower pressure to gently erode an entry hole before ramping up to full cutting pressure. We also use “ramping,” where the nozzle enters while moving rather than staying stationary.

-900x375.webp)